SANDPIPER ELECTRO-PNEUMATIC SPEED CONTROL SYSTEM User Manual

Page 3

spdctrol-rev0808

Speed Control Page 3

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568 • Mansfi eld, OH 44901 USA • (419) 524-8388 Fax (419) 522- 7867

www.warrenrupp.com

INSTALLATION & CONNECTION

Mechanical Connections: Plumb the outlet of

the air piloted regulator (procedure explained earlier) to

the inlet of the diaphragm pump. Plumb the inlet of the

air piloted regulator to the supply air. Supply air must

be clean, dry compressed air, not to exceed 125 psi.

Mount the control box in desired location.

Electrical Connections: The Warren Rupp

Speed Control System 032-022-000 is shipped

standard, set up for 110V. Speed Control System

032-023-000 is shipped standard, set up for 220V.

The units are marked accordingly on the exterior and

interior of the Power Supply Module. Be certain you

have the correct unit before installing. Connect

the AC incoming power to terminal on Power Supply

marked L1 and L2.

DO NOT USE neutral (ground) wire.

If the Warren Rupp Speed Control is to be used

as a stand-alone control device (no remote controller

used to provide command signal) the switch on the

outside of the control box ("Manual/Automatic") should

remain in the Manual position. In this scenario, any

desired changes in pressure output of the valve are

made by simply adjusting the potentiometer knob on

the face of the control panel. Clockwise turning of the

potentiometer increases the pressure speed and out-

put. Counter clockwise movement decreases speed

and output.

NOTE: Each input volt equals 12.5 psi output

pressure. For example, at 65 psi input, the potenti-

ometer would operate between minimum and half-

way to maximum on the dial to achieve maximum

performance of this unit. (See Fig. 6).

If a remote controller is used to provide a 4-20

mA command signal, locate the small circuit board on

the inside of the face plate of the control box. Connect

4-20 + to terminal marked S+. Connect 4-20 - to terminal

marked S-. (See Figure 5.) In this scenario, when the

switch on the outside of the control box marked Manual/

Automatic is in the Manual position, the command sig-

nal is from the potentiometer on the face of the control

panel. When the switch is in the Automatic position,

the command signal comes from the 4-20 mA control

signal supplied by the remote controller.

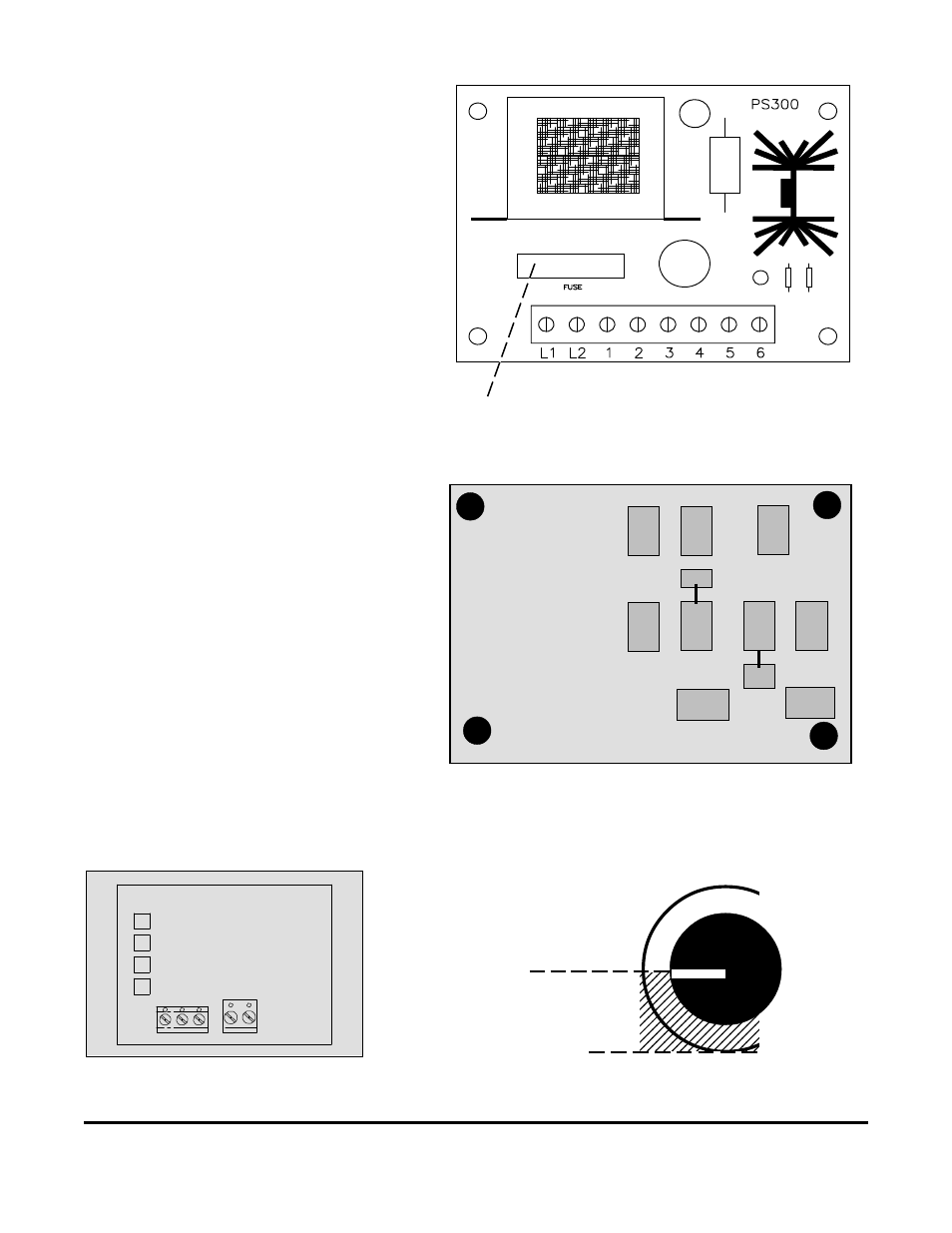

Front View of Power Supply Module

Figure 5

PS-300

A

B

C

D

E

F

Figure 4

Rear View of Power Supply Module

3 amp Fuse: Replacement Part 358-001-000

Minimum

Maximum

Operating range of this unit

at 65 psi input pressure.

This setting represents

maximum performance at

approximately 65 psi input

pressure.

Figure 6

Do not exceed 125 psi input

pressure.

POTENTIOMETER

MANUAL CONTROL KNOB

S-

S+