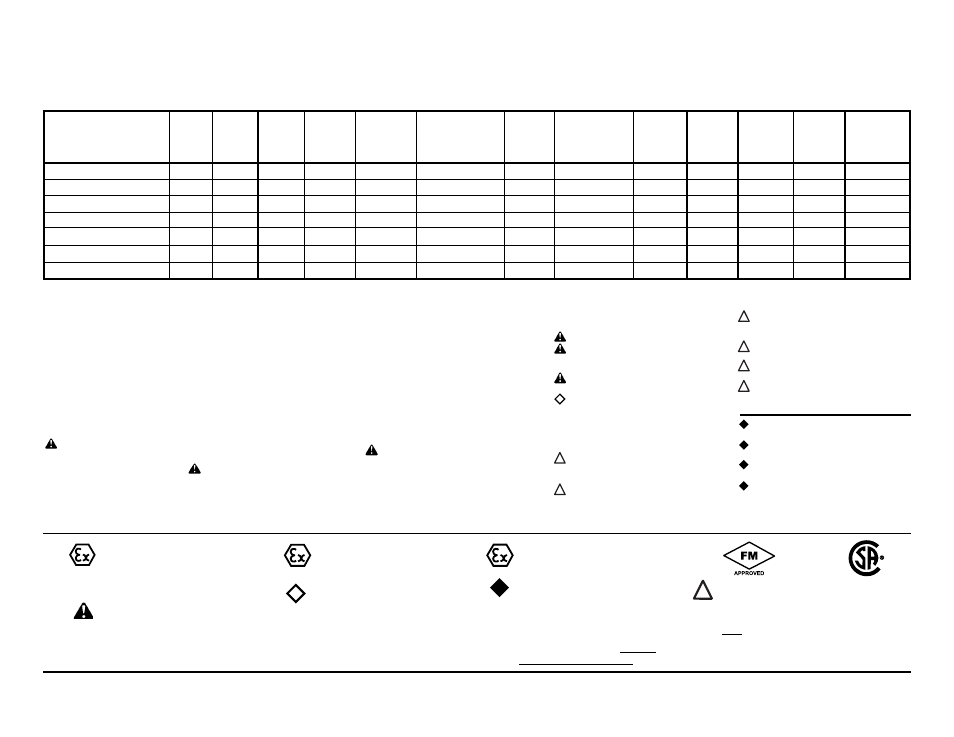

Explanation of pump nomenclature, M15 non-metallic · design level 3 · ball valve – SANDPIPER M15 Non-Metallic User Manual

Page 4

m15nmdl3sm-rev0713

Model M15 Non-Metallic Page 2

Check

Diaphragm/

Check

Non-Wetted

Shipping

Model

Pump Pump Valve Design Wetted

Check Valve Valve

Material

Porting Pump Pump

Kit

Weight

Brand Size

Type

Level Material

Materials

Seat

Options Options Style Options Options lbs. (kg)

M15B3P1PPAS000.

M

15

B 3 P

1

P P A S 0 00.

80 (36)

M15B3K1KPAS000.

M

15

B 3 K

1

K P A S 0 00.

108

(49)

M15B3P2PPAS000.

M

15

B 3 P

2

P P A S 0 00.

83

(34)

M15B3K2KPAS000.

M

15

B 3 K

2

K P A S 0 00.

112

(51)

M15B3PGPPAS000.

M

15

B

3

P

G

P

P

A

S

0

00

109 (50)

M15B3KGKPAS000.

M

15

B 3 K

G K P A S 0 00

112

(51)

M15B3C1PCAS000.

M

15

B 3 C

1

P C A S 0 00.

84(38)

M15 Non-Metallic · Design Level 3 · Ball Valve

Explanation of Pump Nomenclature

Pump Brand

M= MARATHON

®

Pump Size

15=1 1/2"

Check Valve Type

B= Ball

Design Level

3= Design Level 3

Wetted Material

K= PVDF

P= Polypropylene

C=Conductive Polypropylene

Diaphragm / Check Valve Materials

1= Santoprene/Santoprene

2= PTFE-Santoprene Backup/PTFE

6= PTFE Pumping, PTFE-Neoprene

Backup Driver/PTFE

B= Nitrile/Nitrile

C= FKM / PTFE

G=PTFE-Neoprene Backup/PTFE

N=Neoprene/Neoprene

U=Urethane/Urethane

Z= One-Piece Bonded/PTFE

Check Valve Seat

K= PVDF

P= Polypropylene

Non-Wetted Material Options

C=Carbon Filled Conductive

Polypropylene

P=40%Glass Filled Polypropylene

1=40%Glass Filled Polypropylene

w/PTFE Coated Hardware

Porting Options

A= ANSI Flange

D= DIN Flange

7= Dual Porting (ANSI)

8= Top Dual Porting (ANSI)

9= Bottom Dual Porting (ANSI)

Pump Style

D= with Electronic Leak Detection (110V)

E= with Electronic Leak Detection (220V)

M=with Mechanical Leak Detection

S= Standard

V= with Visual Leak Detection

Pump Options

0= None

1= Sound Dampening Muffler

2= Mesh Muffler

3= High temperature Air Valve

w/Integral Muffler

4= High temperature Air Valve

w/Sound Dampening Muffler

Kit Options

continued

E5.= Solenoid Kit with 110VAC

Explosion-Proof Coil

E6.= Solenoid Kit with 220VAC Coil

E7.= Solenoid Kit with 220VAC

Explosion-Proof Coil

E8.= Solenoid Kit with 110VAC, 50 Hz

Explosion-Proof Coil

E9.= Solenoid Kit with 230VAC, 50 Hz

Explosion-Proof Coil

SP.= Stroke Indicator Pins

A1.= Solenoid Kit with 12 VDC

ATEX Compliant Coil

A2.= Solenoid Kit with 24 VDC

ATEX Compliant Coil

A3.= Solenoid Kit with 110/120 VAC

50/60 Hz ATEX Compliant Coil

A4.= Solenoid Kit with 220/240 VAC

50/60 Hz ATEX Compliant Coil

Pump Options continued

5= High temperature Air Valve

w/Mesh Muffler

6= Metal Muffler

7= Metal Muffler w/ Grounding Cable

Kit Options

00.= None

P0.= 10-30VDC Pulse Output Kit

P1.= Intrinsically-Safe 5-30VDC,

110/120VAC 220/240 VAC

Pulse Output Kit

P2.= 110/120 or 220/240VAC

Pulse Output Kit

E0.= Solenoid Kit with 24VDC Coil

E1.= Solenoid Kit with 24VDC

Explosion-Proof Coil

E2.= Solenoid Kit with 24VAC/12VDC Coil

E3.= Solenoid Kit with 12VDC

Explosion-Proof Coil

E4.= Solenoid Kit with 110VAC Coil

Note: Models listed in the table are for reference only. See nomenclature below for other models.

*Note: See page 20 for

Special

Conditions For Safe Use.

Note: Pumps are only ATEX

compliant when ordered with

wetted material option C, non-

wetted material option C, pump

option 0, 6 or 7, and kit option 0.

II 2GD T5

(1)

Note: Pumps ordered

with the options listed in

(1) to the left are ATEX

compliant when ordered

with kit option P1.

II 2G Ex ia c IIC T5

II 2D c iaD 20 IP67 T100˚C

(2)

Note: Pumps ordered with the options listed

in (1) to the left are ATEX compliant when

ordered with kit option A1, A2, A3, or A4.

Compressed Air Temperature Range: Maxi-

mum Ambient Temperature to plus 50°C.

II 2G EEx m c T5

II 2D c IP65 T100°C

(3*)

IEC EEX m T4

Note: Pump models equipped with these

explosion-proof solenoid kit options E1,

E3, E5, E7, E8 or E9, are certified and

approved by the above agencies. They are

NOT ATEX compliant.

(4)

II 1G c T5

II 3/1 G c T5

II 1D c T100°C

I M1 c

I M2 c

II 2G Ex ia c IIC T5

II 3/2 G Ex ia c IIC T5

II 2D Ex c ia 20 IP67 T100°C

II 2G EEx m c II T5

II 3/2 2G EEx m c II T5

II 2D c IP65 T100°C