St40-a, Explanation of pump nomenclature, st1½ & st40, Type 4 – SANDPIPER ST40 User Manual

Page 4: Containment duty, Materials, Materials of construction, Ii 2gd t5, I m2 c t5 ii 2gd t5, Sandpiper, Containment duty pumps: sealless safety

st15dl4sm-rev0614

Models ST1½, ST40 Page 2

Explanation of Pump Nomenclature, ST1½ & ST40

II 1 G c T5

II 3/1 G c T5

II 1 D c T100oC

I M1 c

I M2 c

Models equipped with Cast Iron, Stainless

Steel, or Alloy C wetted parts, and Cast Iron

midsection parts. See page 6 for ATEX

Explanation of EC-Type Certificate.

II 2GD T5

II 2 G c T5

II 3/2 G c T5

II 2 D c T100oC

All models, including pumps equipped with

Aluminum wetted and midsection parts.

See page 6 for ATEX Explanation of

Type Examination Certificate.

II 2GD T5

ST1½ -A: 1½"

(37.5mm)

NPT(F)

ST40-A: 1½"

(37.5mm)

BSP(F)

0 to 90 gallons per minute

(0 to 340 liters per minute)

Occasional solids only.

up to ¼"

(6.3mm)

125 psi or 289 ft. of water

(8.8 Kg/cm

2

or 88 meters)

Viton

®

is a registered tradenames of E.I. du Pont.

SPST1½A-REV0807

No-lube, non-stall

design.

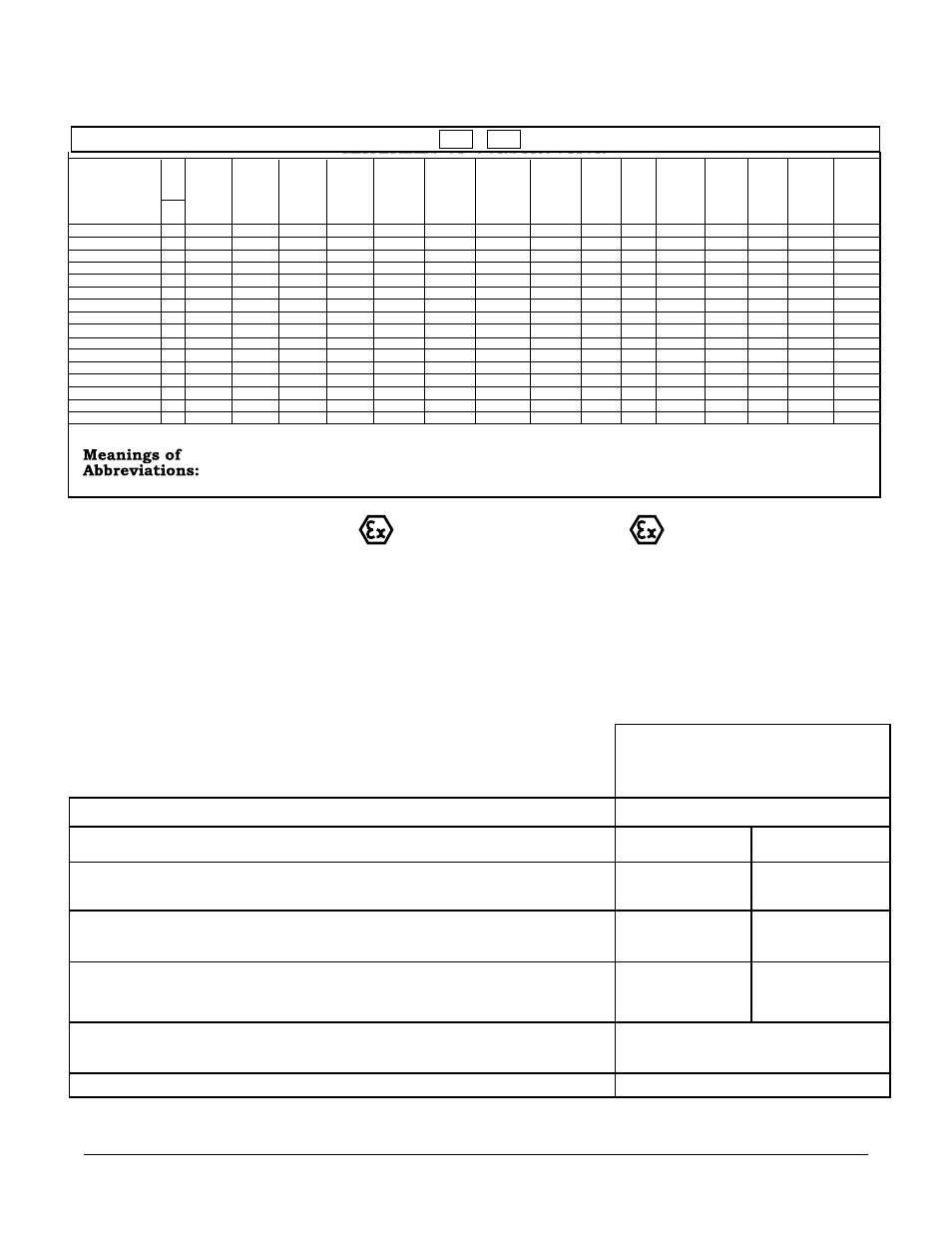

AL = Aluminum

CI = Cast Iron

DC = Die Cast

SS = Stainless Steel

DI = Ductile Iron

T = PTFE

T/I = PTFE Diaphragm/EDPM Driver

T/N = PTFE Diaphragm/Neoprene Driver

T/V = PTFE Diaphragm/Viton

®

Driver

WR-S = Warren Rupp Alloy Type 316 Stainless Steel

WR-C = Warren Rupp Alloy "C" (Hastelloy C equivalent)

Kit available to convert to top or bottom porting.

SGI-4-A

X

AL356T6 AL356T6 AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/I

T

T

T

99

SGN-4-A

X

AL356T6 AL356T6 AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/N

T

T

T

99

SGV-4-A

X

AL356T6 AL356T6 AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/V

T

T

T

99

SGI-4-SS

X

WR-S

WR-S

AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/I

T

T

T

146

SGN-4-SS

X

WR-S

WR-S

AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/N

T

T

T

146

SGV-4-SS

X

WR-S

WR-S

AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/V

T

T

T

146

SGI-4-HC

X

WR-C

WR-C

AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/I

T

T

T

146

SGN-4-HC

X

WR-C

WR-C

AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/N

T

T

T

146

SGV-4-HC

X

WR-C

WR-C

AL356T6 AL356T6

316SS

AL380DC

AL356T6

416SS

316SS 304SS

T/V

T

T

T

146

SGI-4-II

X

CI

CI

CI

DI

316SS

CI

CI

416SS

316SS 304SS

T/I

T

T

T

212

SGN-4-II

X

CI

CI

CI

DI

316SS

CI

CI

416SS

316SS 304SS

T/N

T

T

T

212

SGV-4-II

X

C

I

CI

CI

DI

316SS

CI

CI

416SS

316SS 304SS

T/V

T

T

T

212

SGN-4-HI

X

CI

DI

316SS

CI

CI

416SS

316SS 304SS

T/N

T

T

T

212

SGV-4-HI

X

WR-C

WR-C

WR-C

WR-C

CI

DI

316SS

CI

CI

416SS

316SS 304SS

T/V

T

T

T

212

SGN-4-SI

X

WR-S

WR-S

CI

DI

316SS

CI

CI

416SS

316SS 304SS

T/N

T

T

T

209

SGV-4-SI

X

WR-S

WR-S

CI

DI

316SS

CI

CI

416SS

316SS 304SS

T/V

T

T

T

209

Type 4

Shipping

Wt.(lbs)

Hard-

ware

Seat

Gasket

Ball

Valve

Material

Diaphragm

Outer

Diaphragm

Plate

Inner

Diaphragm

Plate

Intermediate

Housing

Diaphragm

Rod

Valve

Seat

Manifold

Gasket

Sealing

Rings

Manif

old

P

or

ting

Side

Manifold

Outer

Chamber

Inner

Chamber

Driver

Chamber

®

pumps are designed to be powered

only by compressed air)

Temperature Limit: 212 F -

100 C MAXIMUM

Performance based on water at

ambient temperature. Average

displacement per pump stroke:

1.14 liters.

Performance based on water at

ambient temperature. Average

displacement per pump stroke:

0.30 gallon.

ST1

-A

Type 4

ST40-A

Type 4

12

Quality System

ISO9001 Certified

Environmental

Management System

ISO14001 Certified

®

®Warren Rupp and SANDPIPER are registered tradenames of Warren Rupp, Inc.

(SANDPIPER

SANDPIPER

®

Models

SANDPIPER

®

Models

Containment Duty

SANDPIPER

®

Containment Duty Pumps: Sealless Safety

This pump is part of the Containment Duty Pumps. It is specially fitted with PTFE diaphragms as well as elastomeric or elastomeric/PTFE driver diaphragms. The liquid-filled spill chambers

provide an additional chemically-resistant barrier, should a pumpIng diaphragm fail. The Spill Containment design gives the pump user advanced warning of diaphragm failure, before

pumpage can damage the air valve or be released into the work environment. Three optional leak detectors available for this model:

• Mechanical VIP Leak Detector 031-025-000 • Electronic Leak Detector (115V) 032-043-000 • Electronic Leak Detector (220V) 032-043-000

The Containment Duty pumps offer many different levels of materials and spill monitoring devices designed to fit a variety of applications and budgets.

I M2 c T5

II 2GD T5

MATERIALS OF CONSTRUCTION

To order a pump or replacement parts, first enter the Model Number ST15, or ST40, followed by the Type Designation listed below in the far left column.

Materials

Operating Temperatures

EPDM Shows very good water and chemical resistance. Has poor resistance to oil and solvents, but is fair in

ketones and alcohols.

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected by moderate chemicals, fats,

greases and many oils and solvents. Generally attacked by strong oxidizing acids, ketones, esters, nitro

hydrocarbons and chlorinated aromatic hydrocarbons.

PTFE Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE: molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as

chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures.

FKM (Fluorocarbon) shows good resistance to a wide range of oils and solvents; especially all aliphatic,

aromatic and halogenated hydrocarbons, acids, animal and vegetable oils. Hot water or hot aqueous solu-

tions (over 70°F) will attack FKM.

Maximum

Minimum

‡

CF-8M Stainless Steel equal to or exceeding ASTM specification A743 for corrosion resistant iron chro-

mium, iron chromium nickel, and nickel based alloy castings for general applications. Commonly referred

to as 316 Stainless Steel in the pump industry.

280°F -40°F

138°C -40°C

200°F -10°F

93°C -23°C

220°F -35°F

104°C -37°C

350°F -40°F

177°C -40°C

Maximum and Minimum Temperatures are the limits for which

these materials can be operated. Temperatures coupled with

pressure affect the longevity of diaphragm pump components.

Maximum life should not be expected at the extreme limits of

the temperature ranges.

For specific applications, always consult “Chemical Resistance Chart" Technical Bulletin

ALLOY C CW-12MW equal to or exceeding ASTM A494 specification for nickel and nickel alloy castings.