4 technical description, 1 system design/principle of operation, 1 optics – LumaSense Technologies IGA 740 User Manual

Page 12: Vario optics, 4 technical, Description, System design/principle of operation, Fig. 1, Structure of the pyrometer

Technical Description

8

KLEIBER

740

4 Technical

Description

4.1 System

Design/Principle of Operation

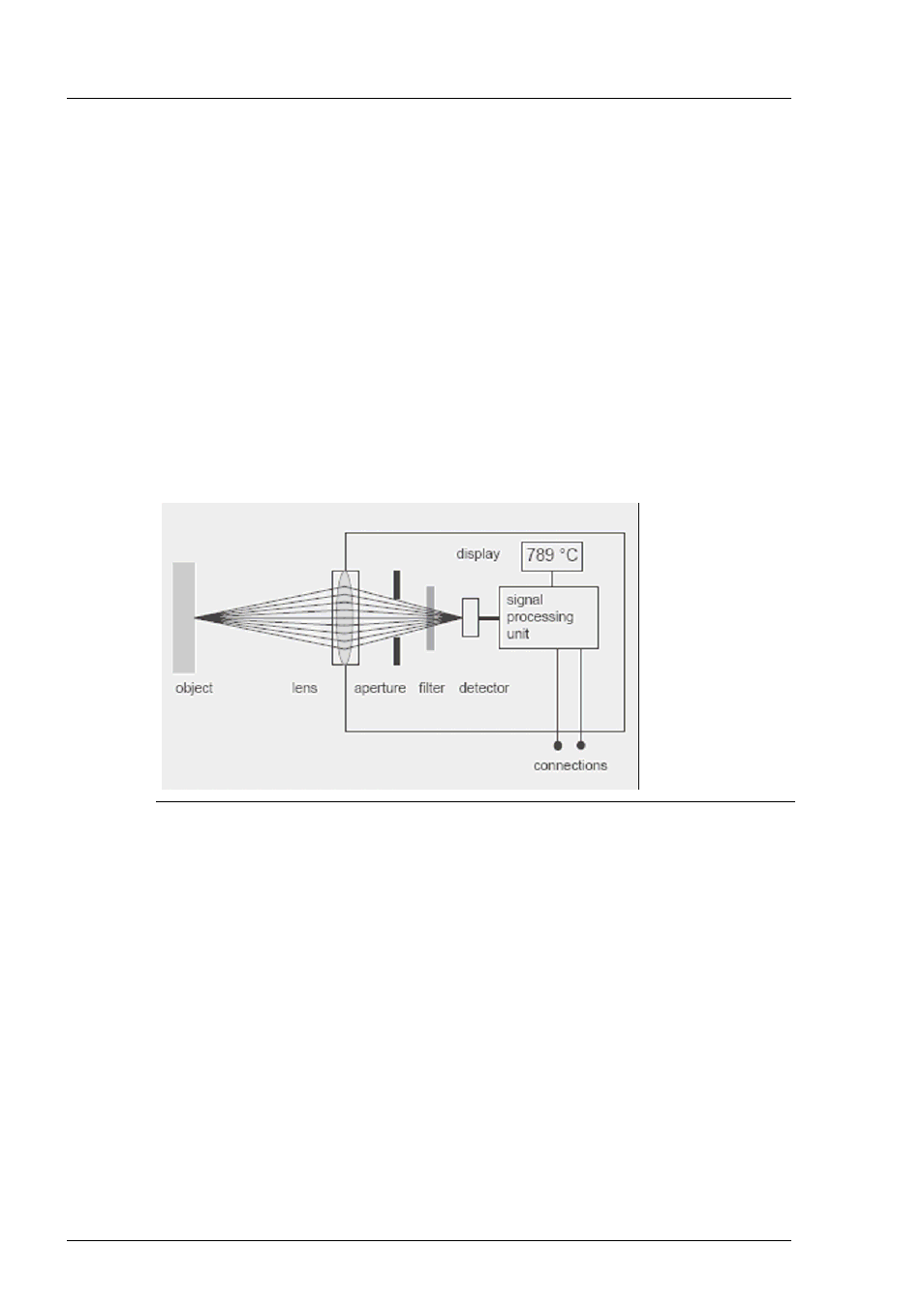

Fig. 1 shows the basic structure of the pyrometer. The basic parts of a pyrometer are the

lens, aperture, filter detector, and the signal processing unit. The infrared radiation coming

in from the object to be measured is gathered by the lens. The aperture blocks unwanted

rays at the edges. The filter permits only the desired spectral range to enter. The rays then

pass through to the detector which transforms the infrared radiation into electric signals.

These signals are then linearised in the signal processing unit and changed into a standard

output signal which can then be read in the display, and be used for process control.

The operating elements as well as the connections/interfaces are located at the back of the

pyrometer (see pages 10 to Fehler! Textmarke nicht definiert.).

The coolant connections are located under the instrument.

Fig. 1

Structure of the pyrometer

4.1.1 Optics

Depending on the application (measuring distance, measuring field diameter, etc.), the

pyrometer is equipped with a vario-optic or a macro-optic.

Vario optics

The Vario optic can be adjusted to the required measuring distance and allows small

measuring fields for various distances to the object being measured. The object being

measured can be at an arbitrary distance, but must be at least as large as the measuring

field at that distance (see section 7.1).