Installation, Caution – Lincoln Electric IM924 POWER WAVE 455M_STT User Manual

Page 15

A-5

INSTALLATION

POWER WAVE 455M/STT (CE)

A-5

Electrode Voltage Sensing

Enabling or disabling electrode voltage sensing is

automatically configured through software. The 67

electrode sense lead is internal to the cable to the wire

feeder and always connected when a wire feeder is

present.

Important: The electrode polarity must be config-

ured at the feed head for all semi-automatic

processes. Failure to do so may result in extreme-

ly high welding outputs.

------------------------------------------------------------------------

POWER WAVE TO SEMI-AUTOMAT-

IC POWER FEED WIRE FEEDER

INTERCONNECTIONS

The Power Wave 455M/STT (CE) and semi-automatic

POWER FEED family communicate via a 5 conductor

control cable (K1543). The control cable consists of two

power leads, one twisted pair for digital communication,

and one lead for voltage sensing. The cables are

designed to be connected end to end for ease of exten-

sion. The output receptacle on the Power Wave

455M/STT (CE) is located beneath the spring loaded out-

put cover at the bottom of the case front. The input recep-

tacle on the Power Feed is typically located at the back of

the feeder, or on the bottom of the user interface.

For convenience sake, the electrode and control cables

can be routed behind the left or right strain reliefs (under

the spring loaded output cover), and along the channels

formed into the base of the Power Wave, out the back of

the channels, and then to the wire feeder.

Due to the flexibility of the platform the configuration may

vary. The following is a general description of the system.

For specific configuration information, consult the semi-

automatic Power Feed instruction manual.

SYSTEM DESCRIPTION

The Power Wave 455M/STT (CE) and Power Feed M

family of products utilize a digital communication system

called ArcLink. Simply put, ArcLink allows large amounts

of information to be passed at very high speeds between

components (nodes) in the system. The system requires

only two wires for communication, and because of its bus-

like structure, the components may be connected to the

network in any order, thus simplifying the system set-up.

Each "system" must contain only one power source.

The number of wire feeders is determined by the type

of wire feeder. Refer to the wire feeder instruction man-

ual for details

Enable the voltage sense leads as follows:

TABLE A.2

Process Electrode Voltage

Work Voltage

Sensing 67 lead *

Sensing 21 lead

GMAW

67 lead required

21 lead optional

GMAW-P 67 lead required

21 lead optional

FCAW

67 lead required

21 lead optional

STT

67 lead required

21 lead required

GTAW

Voltage sense at studs

Voltage sense at studs

GMAW

Voltage sense at studs

Voltage sense at studs

SAW

67 lead required

21 lead optional

CAC

Voltage sense at studs

Voltage sense at studs

* The electrode voltage 67 sense lead is integral to the

control cable to the wire feeder.

Work Voltage Sensing

The standard Power Wave 455M/STT

(CE)

is shipped

with the work voltage sense lead enabled.

For processes requiring work voltage sensing, connect

the (21) work voltage sense lead (K940) from the Power

Wave work sense lead receptacle to the work piece.

Attach the sense lead to the work piece as close to the

weld as practical, but not in the return current path.

Enable the work voltage sensing in the Power Wave as

follows:

1. Turn off power to the power source at the disconnect

switch.

2. Remove the front cover from the power

source.

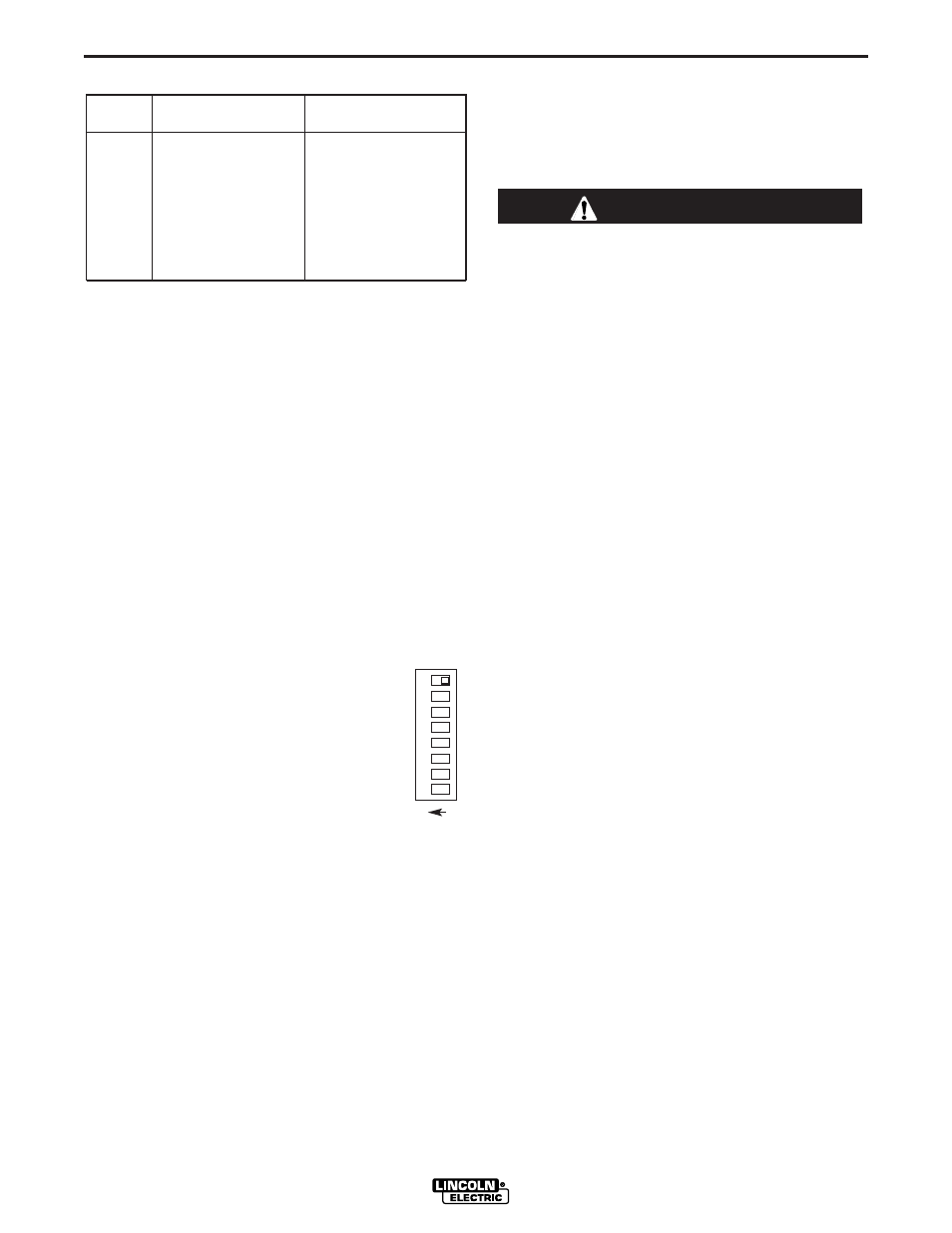

3. The control board is on the left side of the

power source. Locate the 8-position DIP

switch and look for switch 8 of the DIP

switch.

4. Using a pencil or other small object, slide

the switch right to the OFF position if the

work sense lead is NOT connected.

Conversely, slide the switch to the ON

position if the work sense lead is present.

5. Replace the cover and screws. The PC board will

“

read

”

the switch at power up, and configure the work

voltage sense lead appropriately.

O

N

1

2

3

456

7

8

CAUTION