Installation, Safety precautions, Can kill – Lincoln Electric IM689 K1780-1 Power Feed 10 Robotic User Manual

Page 9: Warning

A-2

INSTALLATION

POWER FEED 10 / R

A-2

SAFETY PRECAUTIONS

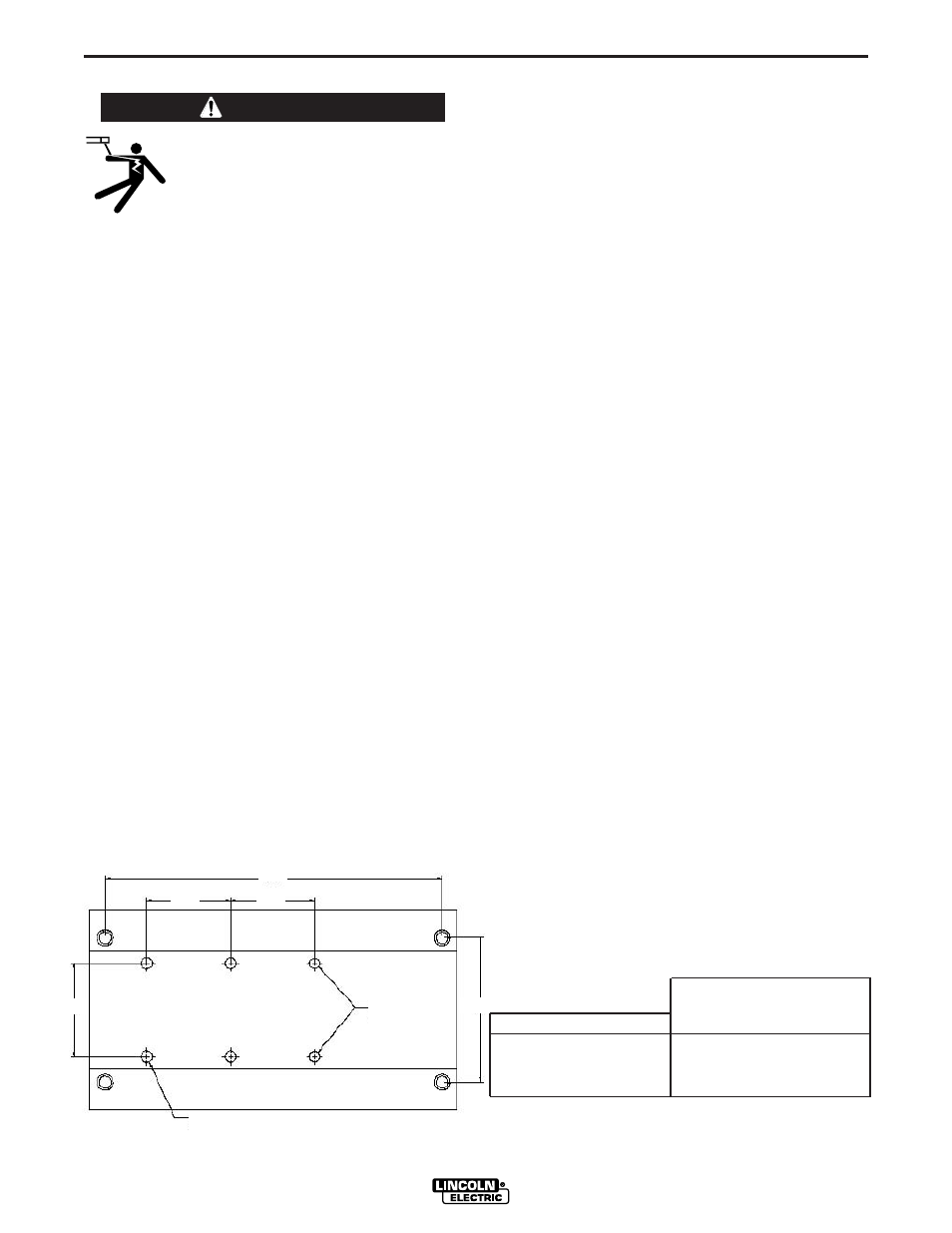

MOUNTING OF THE PF10/R

Mount the wire drive unit by means of the 4 holes in

the bottom of the wire drive base. Note that the gear-

box assembly is electrically “hot” when welding.

Therefore, make certain the gearbox does not come in

contact with the structure on which the unit is mount-

ed. The wire feed unit should be mounted so that the

drive rolls are in a vertical plane to prevent the accu-

mulation of dirt in the drive roll area. Do not bend the

conduit more than 45°.

FIGURE A.1

ELECTRODE ROUTING

The electrode supply may be either from reels, Readi-

Reels, spools, or bulk packaged drums or reels.

Observe the following precautions:

• Do not bend the conduit more than 45°, and to use

the minimum amount of conduit necessary for the

wire reel to connect to the wire feeder.

• The electrode is "hot" while welding and must be

insulated from the boom, conduit and wire payoff

structure.

• If more than one wire feed unit shares the same

boom and are not sharing the some power source

output stud, their wire and reels must be insulated

from each other as well as insulated from their

mounting structure.

ELECTRODE AND WORK CABLE CON-

NECTIONS

Most welding applications run with the electrode being

positive (+). For those applications, connect the elec-

trode cable between the wire feeder and the positive

(+) output stud on the power source (located beneath

the spring loaded output cover near the bottom of the

case front).

A work lead must be run from the negative (-) power

source output stud to the work piece. The work piece

connection must be firm and secure, especially if

pulse welding is planned. Excessive voltage drops at

the work piece connection often result in unsatisfacto-

ry pulse welding performance.

Connect a work lead of sufficient size and length (per

TABLE 1) between the proper output terminal on the

power source and the work. Be sure the connection

to the work makes tight metal-to-metal electrical con-

tact. To avoid interference problems with other equip-

ment and to achieve the best possible operation, route

all cables directly to the work or wire feeder. Do not

bundle the electrode and work leads tightly together.

Avoid excessive lengths and do not coil excess cable.

Use K1796 Coaxial welding cables wherever possible.

Minimum work and electrode cables sizes are as follows:

TABLE 1

Current (60% Duty Cycle)

400 Amps

500 Amps

600 Amps

ELECTRIC SHOCK

can kill.

• Only qualified personnel should

perform this installation.

• Turn off the input power to the power source at

the disconnect switch or fuse box before work-

ing on this equipment. Turn off the input power

to any other equipment connected to the weld-

ing system at the disconnect switch or fuse

box before working on this equipment.

• Do not touch electrically hot parts.

• Always connect the Power Wave grounding lug

(located inside the reconnect input access

door) to a proper safety (Earth) ground.

----------------------------------------------------------------------------------------

MINIMUM COPPER WORK

CABLE SIZE, AWG

Up To-100 Ft. Length (30 m)

2/0 (67 mm2)

3/0 (85 mm2)

3/0 (85 mm2)

WARNING

7.11

1.77

1.77

1.97

3.05

.25 DIA.

(4 Places)

.22 DIA.

(2 Places)