Troubleshooting, Caution – Lincoln Electric IM777 POWER FEED 10M Dual WIRE FEEDER User Manual

Page 59

E-10

TROUBLESHOOTING

E-10

POWER FEED

®

10M DUAL WIRE FEEDER

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

Observe all Safety Guidelines detailed throughout this manual

Error Codes for the Power Wave 455: Code 10675 and above.

ERROR CODES FOR THE POWER WAVE 455

As a troubleshooting aid, error code information will now persist on the user interface displays even after a fault is

cleared. When a fault occurs that the user interface needs to display, welding will be held back for 5 seconds. If

the fault has cleared, the error code information can be removed from the displays by pressing the Reset button,

by changing a user interface control or by starting a new weld.

The following is a list of possible error codes that the Power Feed

®

10M Dual Wire Feeder can output via the dis-

play on this user interface.

Note: For any Err # listed below write down the error number for reference and try cycling power to see if the

error clears itself. If not, refer to the What to Do column for the given Err.

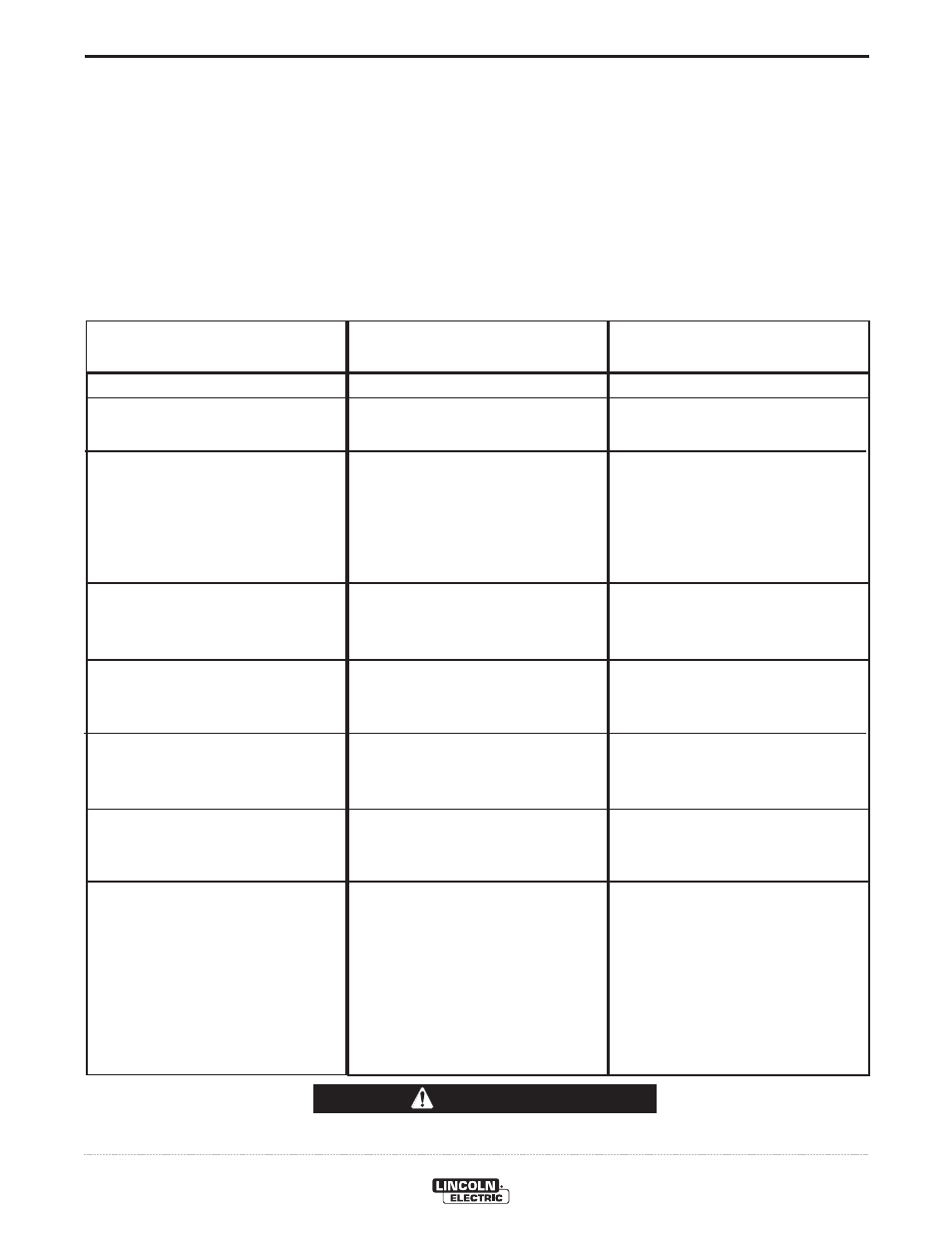

PROBLEMS

(SYMPTOMS)

POSSIBLE CAUSE

RECOMMENDED

COURSE OF ACTION

Display shows any of the following:

Err 11

Err 12

Err 21

Err 22

Err 23

Err 31

Err 32

Err 33

CAN communication bus off.

User Interface time out error.

Unprogrammed Weld Mode.

Empty Weld Table.

Weld Table checksum error.

Primary overcurrent error.

Capacitor "A" under voltage.

(Left side facing machine)

Capacitor "B" under voltage.

(Right side facing machine)

Probably due to excessive number

of communication errors.

User Interface is no longer respond-

ing to the Power Source. The most

likely cause is a fault/bad connection

in the communication leads or con-

trol cable.

Contact the Service Department for

instructions on reloading the Welding

Software.

Contact the Service Department for

instructions on reloading the Welding

Software.

Contact the Service Department for

instructions on reloading the Welding

Software.

Excessive Primary current present.

May be related to a switch board or

output rectifier failure.

Low voltage on the main capacitors.

May be caused by improper input

configuration.

When accompanied by an overvolt-

age error on the same side, it indi-

cates no capacitor voltage present

on that side, and is usually the result

of an open or short in the primary

side of the machine.