Operation, Recommended processes and equipment, Controls and settings – Lincoln Electric IM351 LN-7 GMA Wire Feeder User Manual

Page 32

B-2

OPERATION

B-2

RECOMMENDED PROCESSES AND

EQUIPMENT

The LN-7 GMA is recommended for use in MIG and

Innershield welding applications, the LN-7 is

recommended for Innershield welding applications.

Both are recommended for use with constant voltage

power sources such as the Idealarc DC-250, 400, or

600, or CV types. The LN-7 GMA is capable of feeding

wires ranging from 0.023 in. through 1/16 in. (0.6

through 1.6 mm) solid, 0.045 in. through 5/64 in. (1.2

through 2.0 mm) Innershield, and 0.062 in. through

5/64 in. (1.6 through 2.0 mm) Outershield electrodes.

The LN-7 is capable of feeding wires ranging from

0.023 in. through 3/32 in. (0.6 through 2.4 mm) solid

and 0.045 in. through 7/64 in. (1.2 through 2.8 mm)

cored.

LN-7 & LN-7 GMA

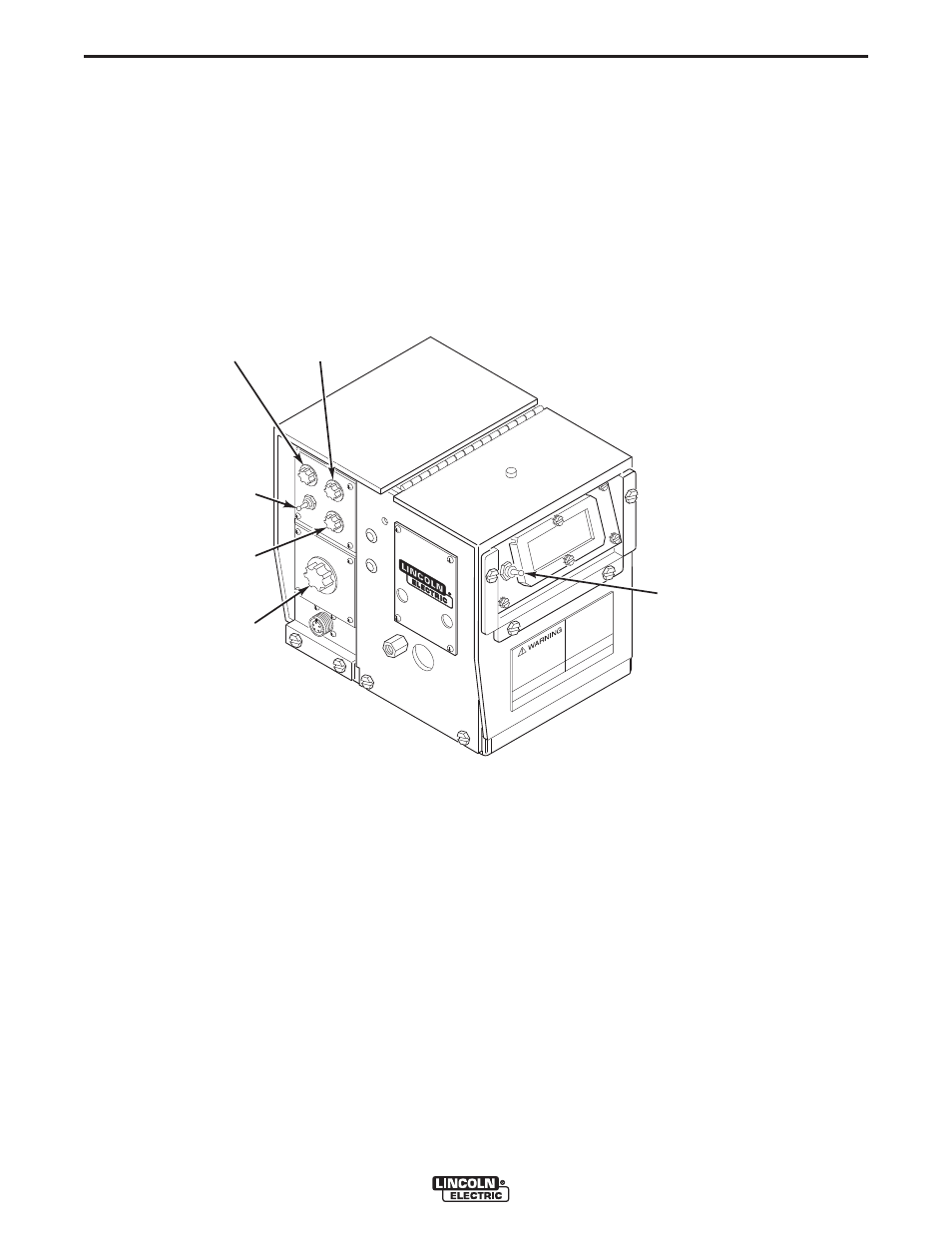

CONTROLS AND SETTINGS

Operator controls are illustrated in Figure B.1. Refer to

the figure and the following explanations of the

controls.

WIRE FEED SPEED CONTROL. This control sets the

feed speed of the wire feeder. Turn the knob to the left

for slower speeds and to the right for higher speeds.

The control is calibrated. The nameplate shows the

wire speed for the given setting of the control.

BURNBACK CONTROL (OPTIONAL). This control,

located on the optional K419 Burnback Timer and

K418 GMA Timer Kits, provides a precise time delay

that allows the wire to be burned off at the end of the

weld. This is useful for those applications where higher

speed, fine wire feeding is used and there is a

tendency for the electrode to overrun at the end of the

weld and cause “sticking” in the crater. The delay is

adjustable for optimum burnback depending on wire

size, process, procedure, etc.

PREFLOW CONTROL (OPTIONAL). This control,

located on the optional K418 GMA Timer Kit, provides

flow of shielding gas to the work before the arc is

established. The gas solenoid valve is energized

immediately when the gun trigger is closed, but the

time delay before the wire feeder is energized is

adjustable from 0 to 1.5 seconds. Turn the knob to the

left for shorter delays and to the right for longer delays.

POSTFLOW CONTROL (OPTIONAL). This control,

located on the optional K418 GMA Timer Kit, provides

flow of shielding gas to the work after welding has

stopped. Delay for the gas solenoid valve shutoff is

adjustable from 0 to 1.5 seconds. Turn the knob to the

left for shorter delays and to the right for longer delays.

POSTFLOW

CONTROL

(OPTIONAL)

PREFLOW

CONTROL

(OPTIONAL)

PURGE-COLD

INCH SWITCH

(OPTIONAL)

WIRE FEED

SPEED CONTROL

ELECTRODE

POLARITY SWITCH

(OPTIONAL)

BURNBACK

CONTROL

(OPTIONAL)

FIGURE B.1 – WIRE FEEDER CONTROLS.