Operation, Spring tension arm, Internal controls – Lincoln Electric IM823 LN-15 WIRE FEEDER User Manual

Page 20

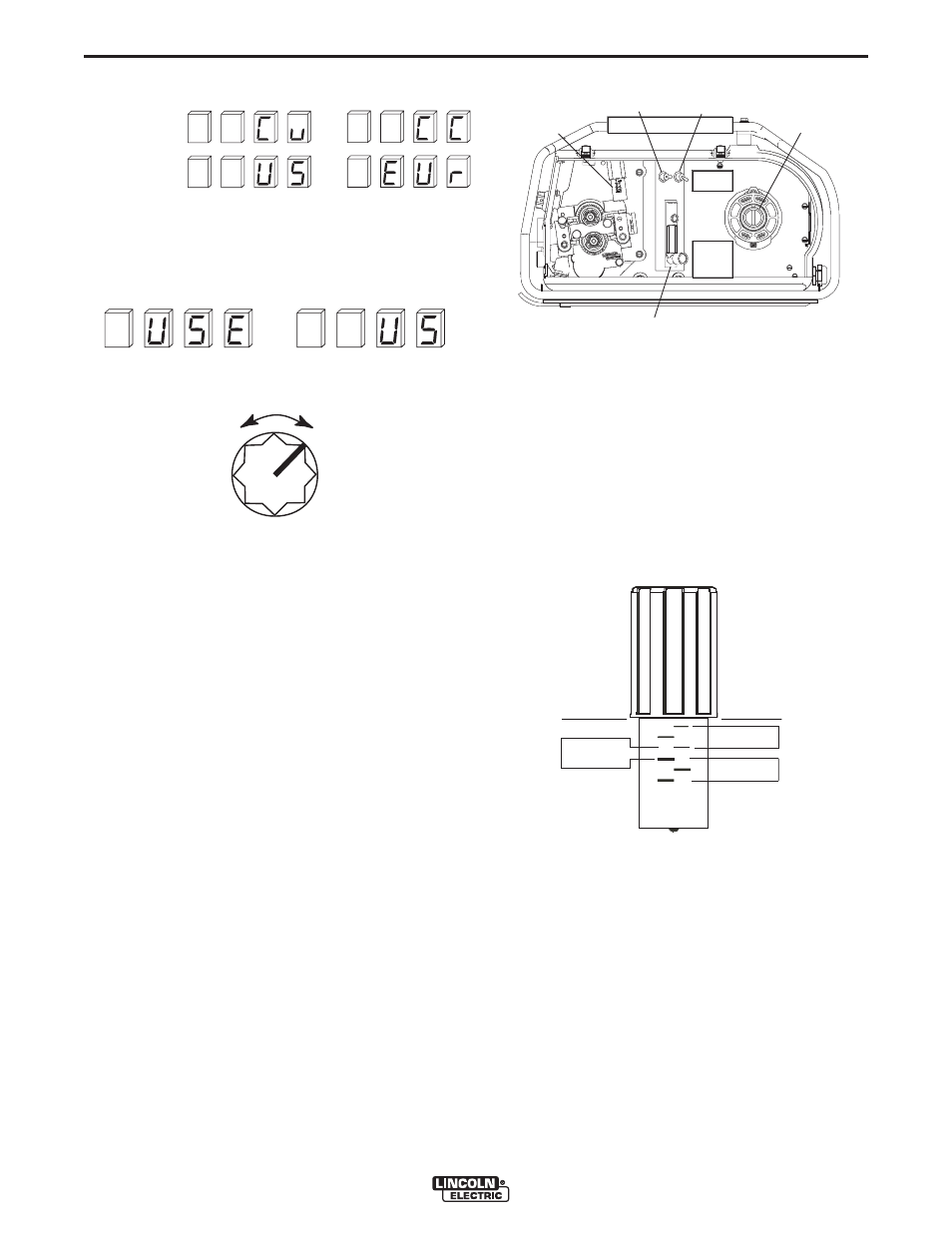

SPRING TENSION ARM

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of both pres-

sure arm gives the best welding performance. For best

results, set both pressure arms to the same value.

Set the pressure arm as follows (See Figure B.2a):

Aluminum wires

between 1 and 3

Cored wires

between 3 and 4

Steel, Stainless wires

between 4 and 6

Figure B.2a

FLOWMETER

SPRING

TENSION

ARM

COLD FEED/

GAS PURGE

SWITCH

2 STEP/TRIGGER

INTERLOCK

SWITCH

SPINDLE

BRAKE

INTERNAL CONTROLS

(Figure B.2)

B-5

OPERATION

B-5

LN™-15 ACROSS THE ARC MODEL & (CE)

Rotate the WFS knob until the desired parameter is

displayed.

CV/CC Mode:

WFS Units:

2. Activate and release the GAS PURGE switch to

select the parameter. The present value will then

display in the right hand side of the display.

Example:

3. Rotate the WFS knob to change the parameter set-

ting.

CV/CC MODE:

• "CU" for Constant Voltage power sources

• "CC" for Constant Current power sources

WFS UNITS:

• "US" for in/min

• "Eur" for m/min

4. Press the GAS PURGE switch to save the setting.

The LN™-15 will then return to the original "Press

Spin" mode in step 1.

5. To exit the "Press Spin" set-up mode, turn off power

to the LN™-15, or simply wait 15 seconds and the

LN™-15 will enter normal operation.

WFS

ALUMINUM

OUTERSHIELD

METALSHIELD

INNERSHIELD

STEEL

STAINLESS

CORED WIRES

SOLID WIRES

6

1

3 2

5 4