Operation – Lincoln Electric IM823 LN-15 WIRE FEEDER User Manual

Page 18

B-3

OPERATION

B-3

LN™-15 ACROSS THE ARC MODEL & (CE)

1

2

3

4

5

6

7

3. WIRE FEED SPEED KNOB

-

The Wire Feed Speed

knob is a 3-3/4 turn potentiometer that adjusts of

the rate of feeding electrode. The wire feed speed

range is 50 - 700 inches/min (1.3 - 17.8 m/min)

4. TRIGGER CONNECTOR-5 Pin Receptacle is used

to activate the Magnum Gun Switch.

5. CONNECTOR BUSHING-This connection is for

welding conductor cable assembly.

6. WORK CLIP LEAD-This lead must be connected

directly to the work using the spring clip.

7. ON / OFF SWITCH-For codes 11033 and above:

The ON / OFF Switch turns power on and off to the

wire feeder.

83% PROCEDURE

The LN™-15 supports a special "dual procedure"

mode. When activated, the wire feed speed is

reduced to 83% of the set value, but no less than 50

inches/minute (1.27 m/min). The 83% procedure is

most commonly used during pipe and out of position

welding. Requires Magnum 400 Dual Procedure Gun

Equivalent.

FIGURE B.1

CASE FRONT CONTROLS

(See Figure B.1)

ACROSS THE ARC MODEL

1. WIRE FEED SPEED DISPLAY-The Wire Feed

Speed display shows the rate the LN™-15 will feed

electrode during welding. The default WFS units

for domestic models are inches/minute and can be

changed to meters/minute through the configuration

menu. The default WFS units for the European

models are m/min. The wire feed speed is calibrat-

ed to within ±2%.

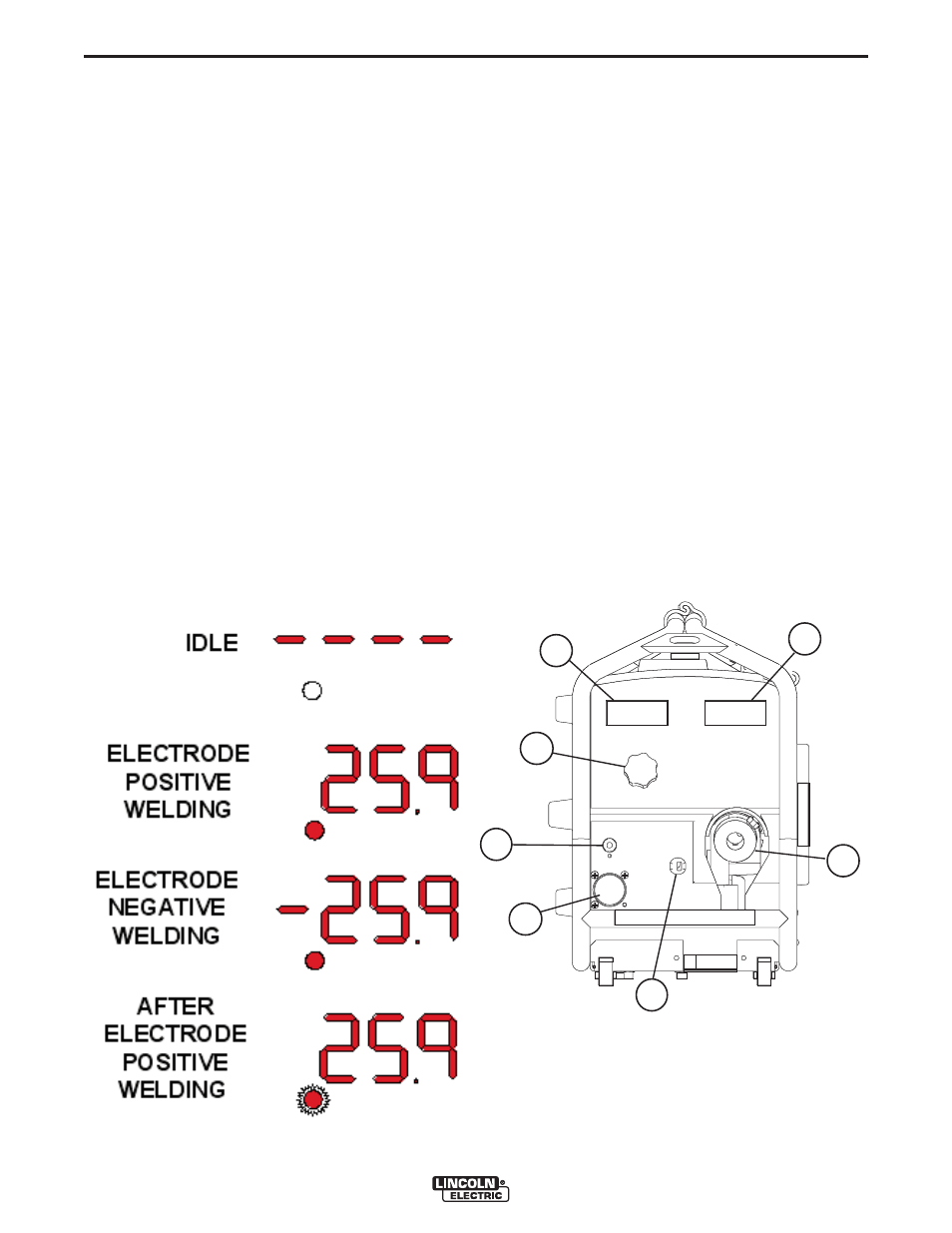

2. VOLTAGE DISPLAY

-

The voltage display shows

the average arc voltage during welding. A minus

sign "-" appears when welding with electrode nega-

tive welding procedures. While welding, an LED

will illuminate below the voltage display. After weld-

ing, the average voltage will continue to be shown

for 5 seconds after the end and the LED will flash.

of the weld. When not welding, the display shows

"- - - ". The voltage is calibrated to ±2% over a

range of 10 to 45 volts.

The voltage display is not a "preset" voltage.

Refer to the examples from Figure B.1a.

FIGURE B.1a