Installation, Mounting products supported, Warning – Lincoln Electric IM512 INVERTEC RACKS User Manual

Page 11: Electrical installation, K912 series of steel racks (8), Mounting k900-1 dc tig starter, Input connection

- 4 -

INVERTEC RACKS

INSTALLATION

K912 Series of Steel Racks (8)

Step 1 Unpack Carton

Remove eight pack carton. Hoist rack 1 ft. above

ground level to remove pallet from rack. With rack on

level surface, remove screws that fasten hood down.

For racks with main disconnect, the switch must be in

the

“

OFF

”

position before the hood can be removed.

Remove hood from rack and take out parts bag and

check against the list provided. K912 series of racks

come with skids and do not require any assembly.

The rack is ready for mounting products supported.

MOUNTING PRODUCTS SUPPORTED

Always check for proper and secure mounting of

equipment before hoisting the rack to high or low ele-

vations.

------------------------------------------------------------------------

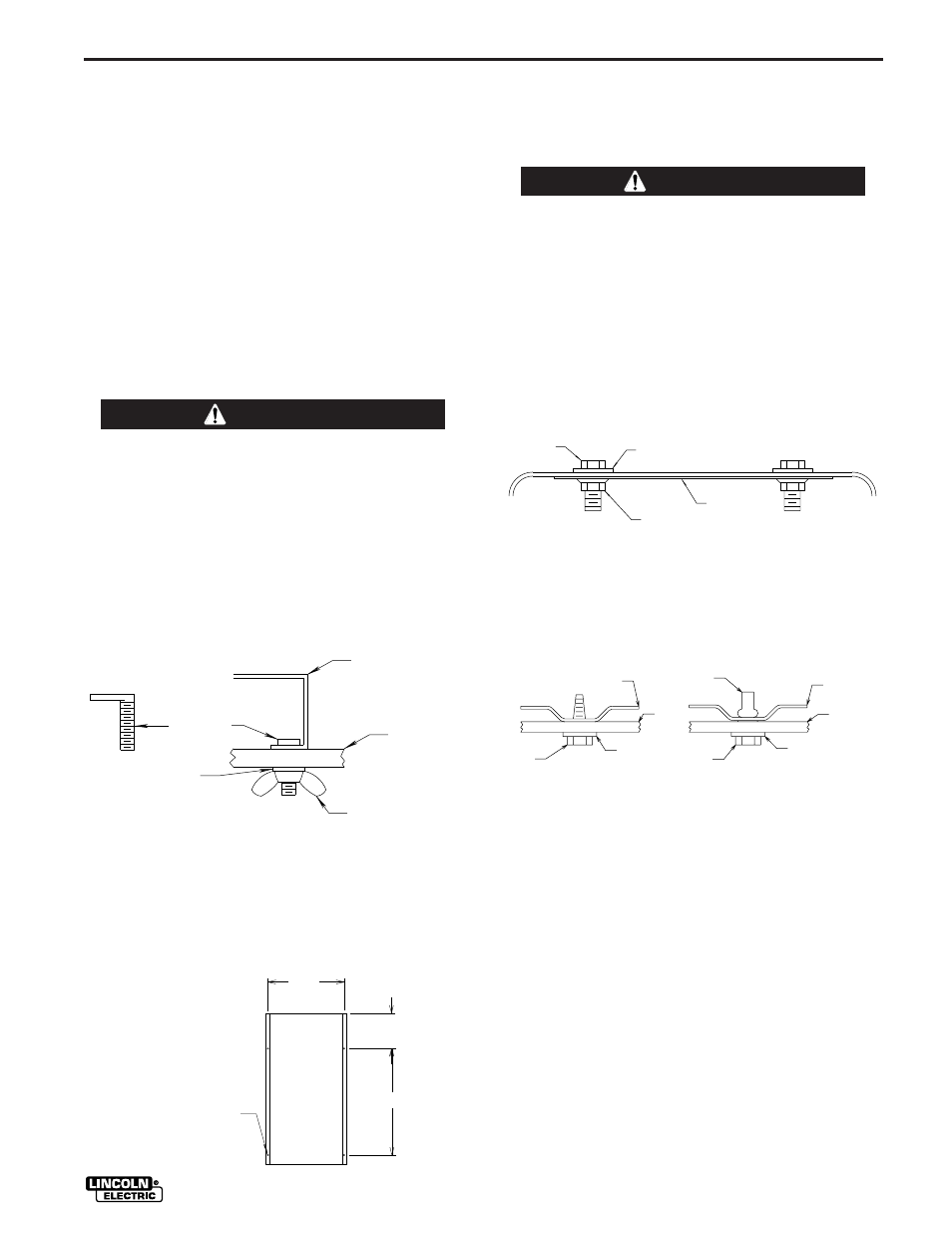

Mounting Power Source

Place power source in rack with controls toward the

front of rack. Align unit with mounting holes. Insert

four #10-24 x .75

”

L-bolts from the top side and

secure each L-bolt as follows:

Mounting K900-1 DC TIG Starter

The Invertec power source handles must be removed

in order to slide the Invertec/TIG unit into the rack.

Follow safety instructions and capacitor discharge

procedure as outlined in owner

’

s manual before ser-

vicing inverter power source.

------------------------------------------------------------------------

Remove handles from Invertec case. Use handle

hardware and flange nuts provided with rack to plug

the holes in the Invertec case, as shown below. A

quantity of eight and sixteen 3/8

”

flange nuts are sup-

plied with four pack and eight pack racks respectively.

Note: Earlier code machines may have insulation

held in place by handle hardware. If so, do not

remove it.

WARNING

L-BOLT

POWER SOURCE

BASE

RACK

SHELF

WING NUT

WASHER

Note:

Earlier code power sources may not have all four or

any mounting holes on the bottom of the base. If

hoisting the rack to high or low elevations is required,

provisions for the use of all four mounting screws

must be made. Use the following dimensions for hole

locations.

4 . 5 0

9 . 6 5

1 3 . 5 0

BACK

BOTTOM

VIEW

FRONT

.22 DIA

(4 PLACES)

WARNING

S C R E W

W A S H E R

F L A N G E N U T

I N S U L A T I O N

( I F P R E S E N T )

Once the handles are removed, follow the instructions

in the TIG Starter Owner

’

s Manual to mount the

Invertec on top of the DC TIG Starter.

Place the Invertec/TIG unit into the rack with controls

toward front of rack. Align unit with mounting holes.

Secure Invertec/TIG unit to shelf as follows:

SCREW

WASHER

RACK

SHELF

TIG BASE

W/O RIVNUTS

RIVNUT

TIG BASE

W/O RIVNUTS

RACK

SHELF

WASHER

#10-32

SCREW

ELECTRICAL INSTALLATION

Racks should be connected only by a qualified electri-

cian. Installation should be made in accordance with

the U.S. National Electrical Code, all local codes and

the information detailed below:

Input Connection

A 2.88

”

hole is provided for input lines for low voltage

operation (208/230V). All racks except K898-3, -4 are

provided with reducing washers for input lines for high

voltage operation (460/575V). Strain relief connectors

for input cables are not supplied with racks. Make sure

connections are secure and water tight. Ground lead

for rack must accompany input lines.