Installation, Warning mechanical installation, Safety precautions – Lincoln Electric IM512 INVERTEC RACKS User Manual

Page 10: K898 series of aluminum racks (4)

INSTALLATION

INVERTEC RACKS

- 3 -

Read entire installation section before starting

installation.

Safety Precautions

ELECTRIC SHOCK can kill.

•

Only qualified personnel should

perform this installation.

•

Turn the input power OFF at the

disconnect switch or fuse box or by

unplugging power cable before

working on this equipment.

•

Do not touch electrically hot

parts.

WARNING

MECHANICAL INSTALLATION

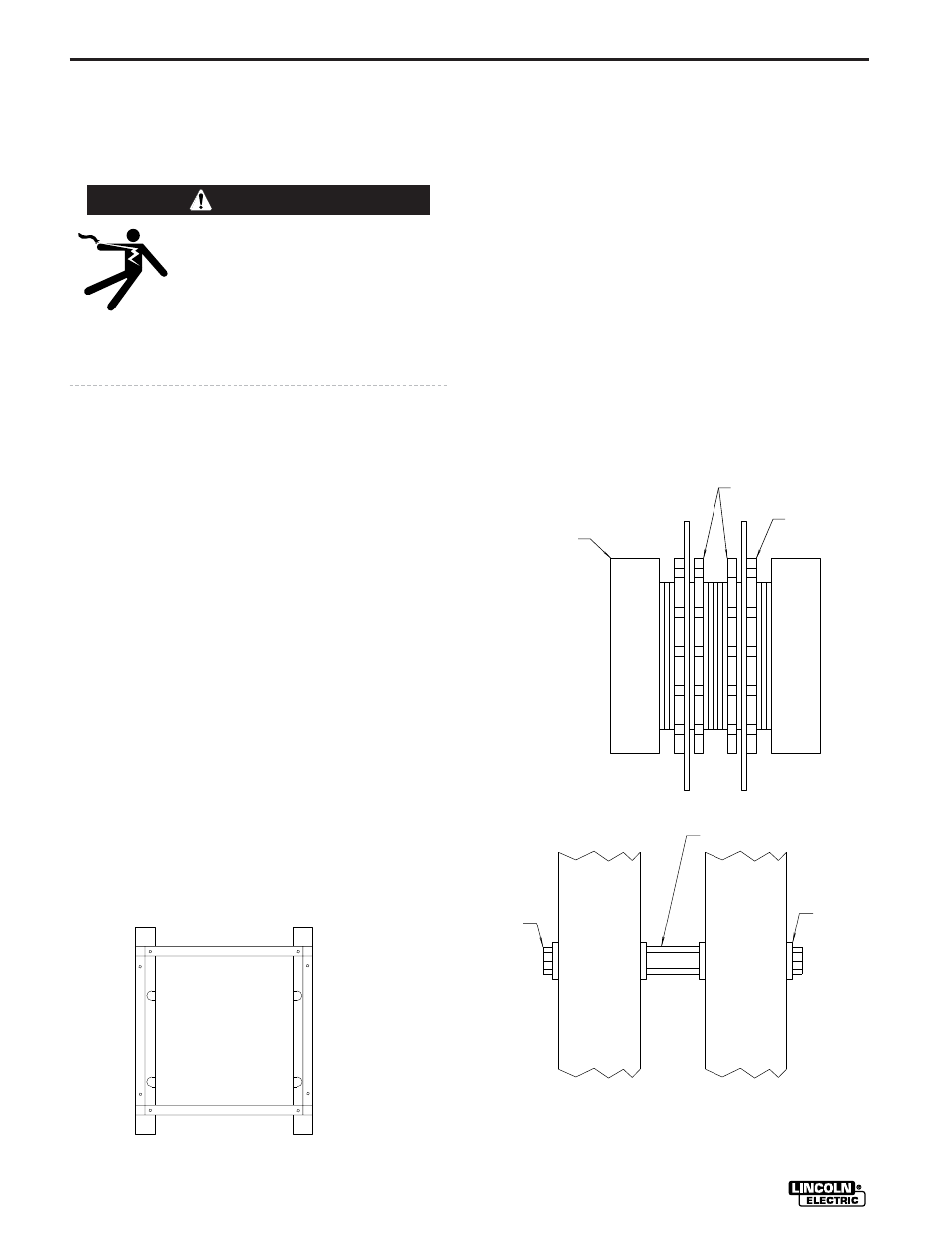

K898 Series of Aluminum Racks (4)

Step 1 Unpack Carton

Remove four pack cartons. Unpack skids and set

aside. Remove hardware mounting rack to pallet.

Remove screws that fasten hood down. For racks

with main disconnect, the switch must be in the

“

OFF

”

position before the hood can be removed. Remove

hood from rack and take out parts bag and check

against the list provided.

Step 2 Attach Skids

Skids can be installed by hoisting rack one foot above

ground level. If hoist is not available, place rack skids

on level surface near rack approximately 27

”

apart

from outside edges. Two-man lift the four pack off

pallet and place onto skids with rack front perpendicu-

lar to skids as shown below. Align holes. Place flat

washer on 1/4 - 20 x 2.25

”

bolt. Insert bolt from the

top side. Place 1/4 - 20 lock nut on bolt from bottom

side. Fasten four bolts and nuts per skid, securely.

The rack is ready for mounting products supported.

Step 3 Attach K898-3, -4 Slave Unit to K898-1, -2

Primary Unit

Attach slave unit to primary unit only after skids or

casters have been installed to both the primary and

slave units.

Remove hood from both racks. Remove 2.00

”

knock-

outs on primary and slave units. Place both racks in

upright position, side-by-side with slave unit to the

right when viewed from the front. Align units so that

the 2.00

”

holes are concentric. Clamp racks together.

Drill six .313

”

diameter clearance holes for a 1/4 - 20

bolt using the slave unit as a guide. Remove clamp.

Join slave unit to primary unit using close nipple with

two steel lock washers and two neoprene lock wash-

ers as shown below. Do not tighten. Assemble slave

unit to primary unit with two 1/4 - 20 x 2.00

”

bolts, 4

flat washers and a rod coupling in six places as shown

below. Tighten lock nuts on close nipple. Cap close

nipple on each end with plastic bushing.

Mounting

Holes

(8 Places)

FRONT

P l a s t i c B u s h i n g

N e o p r e n e

L o c k W a s h e r

S t e e l

L o c k W a s h e r

C L O S E N I P P L E

C O N N E C T I O N

B o l t

R o d C o u p l i n g

W a s h e r

B o l t

C o n n e c t i o n s