Cleaners, disinfectants and descalents, Storage, Trouble shooting guide – Stuart Turner Self Priming Jet 90 Centrifugal User Manual

Page 13

- 13 -

3.

Turn off water supplies to the pump and release pressure by opening outlets before

attempting maintenance.

4.

If the installation is fitted with a footvalve and strainer or inline suction strainer, the

strainer must be cleaned as necessary to ensure the pump has unrestricted flow.

5.

After maintenance is completed, refer to commissioning section for instructions on

restarting pump.

Cleaners, Disinfectants and Descalents

On installations where chemical disinfectants or descalents are periodically

used, the compatibility of the chemical solution regarding the pump must be

considered.

Acid based descalents and aggressive cleaning agents must not come into

contact with the pump. The pump must be removed from the system prior to the

use of these products. The system should be flushed to remove all chemicals

before the pump is re-connected.

If in any doubt as to the suitability of the chemical solutions refer to Stuart

Turner Ltd.

STORAGE

If this product is not installed immediately on receipt, ensure that it is stored in a dry,

frost and vibration free location in its original packaging.

TROUBLE SHOOTING GUIDE

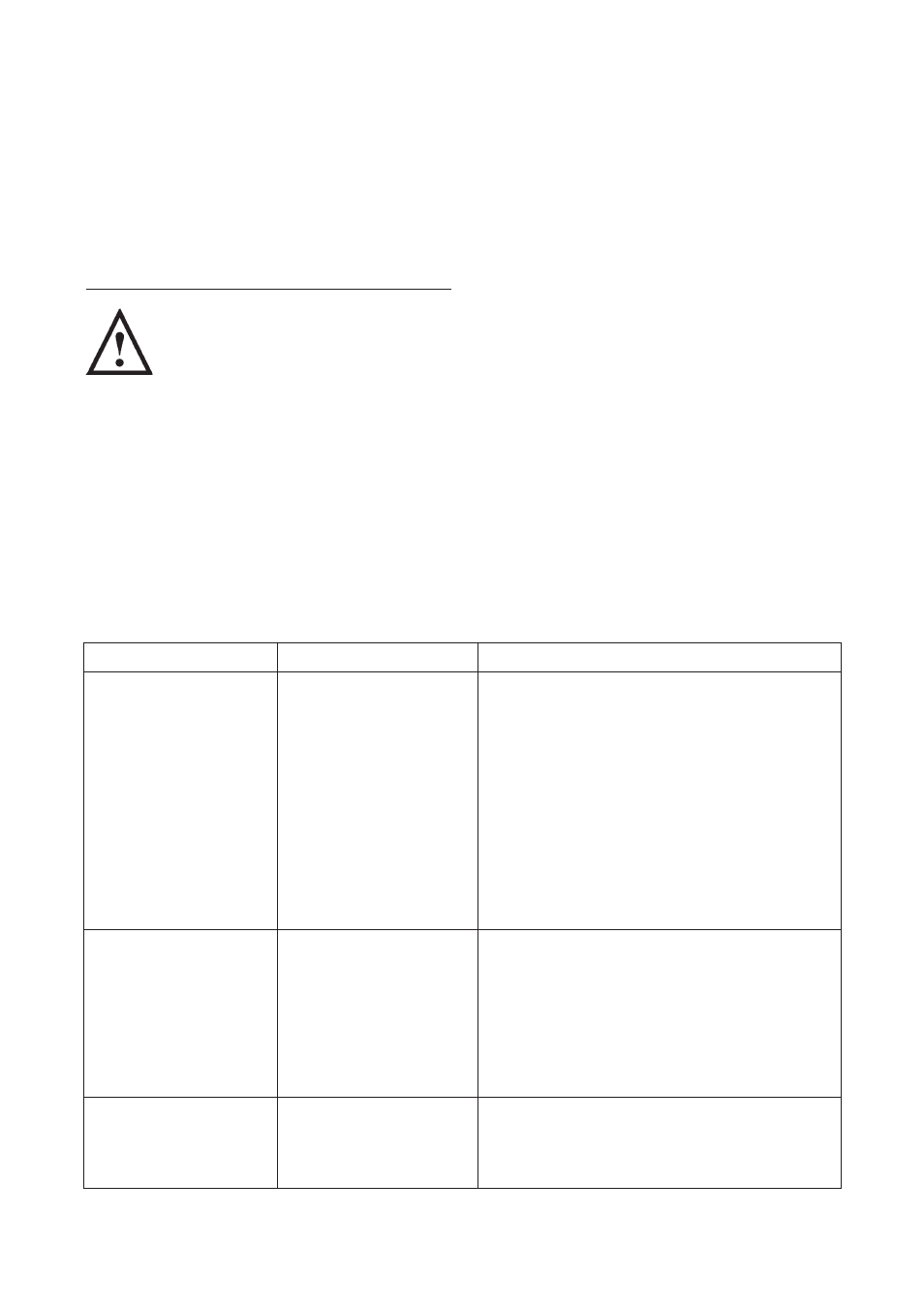

Symptoms

Probable Cause

Recommended Action

Pump will not start.

Inlet filter/strainer blocked (if

fitted).

Electrical supply.

Pump run on hot water which

has caused the integral motor

thermotrip to activate.

Integral motor thermotrip

activated.

Integral on/off switch in off

position.

Remove and clean filter gauze/strianer.

Check all electrical switches are on.

Is the correct fuse fitter?

Is the circuit breaker set?

Wait for thermotrip to cool an auto-reset.

Check water temperature.

Wait for thermotrip to cool and auto-reset.

Investigate cause of problem.

Switch to on postiion.

Pump runs, but no water.

Pump air locked.

Water supply low.

Blocked suction pipe.

Air bubbles in suction pipe.

Remove priming plug, fill with water.

Refit plug.

Check water level in the supply tank or well and all stopcocks

are open.

Check outlet not restricted or blocked.

Clean footvalve/strainer.

Check connections are all airtight.

Pump runs but no water on

suction lift installation.

Lack of priming water.

Insufficient time allowed for

priming to be completed.

Prime pump casing.

Amount of time taken to prime suction pipe will vary

dependent upon model selected and suction lift height.

After 5 minutes repeat priming procedure.