Stuart Turner PH 45 TS S User Manual

Page 11

- 11 -

Cont ...

2. Liquid

Supply

Always ensure that liquid storage capacity is adequate to meet the demand.

Ensure the pump chamber is full of liquid before starting the pump. Failure

to do this could result in seal damage. To ensure dry running does not

occur the pumps must be primed as described in the priming section. Do

not run pump dry.

3. Ensure electrical supply is compatible with the details that are stated on the pump

rating plate. (The wrong voltage or frequency can be dangerous and may damage

the

pump.)

4. Priming

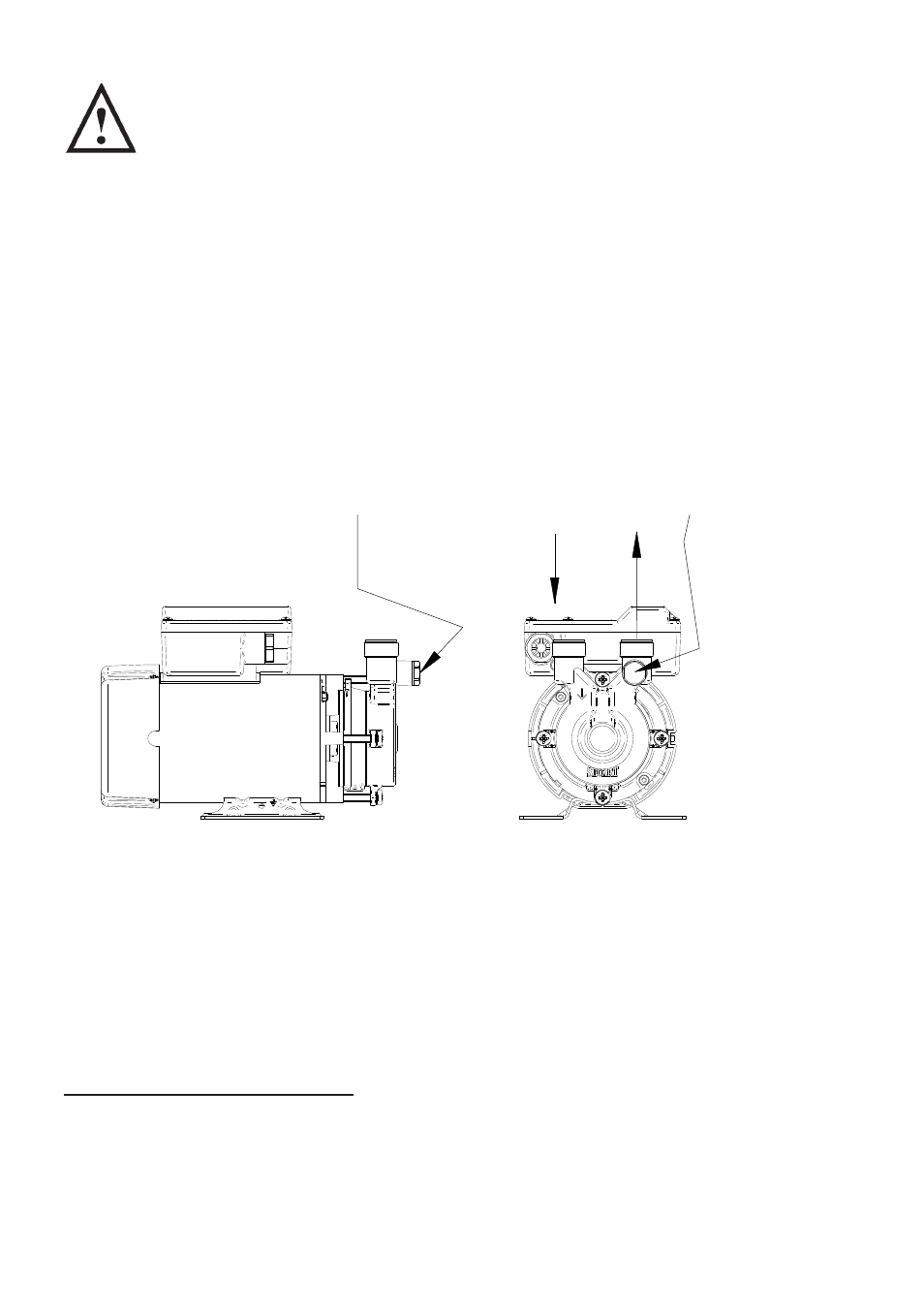

a) Top suction model (flooded suction)

The pump must be primed (filled with liquid) before starting. Turn on liquid

supply, prime and vent the pump by unscrewing the priming plug (Fig. 7)

slowly until all air escapes and liquid emerges. Ensure the ‘O’-ring seal is retained

in place. Re-tighten the plug.

b) All models (suction lift installation)

Prime the suction pipework and pump by filling with liquid via the pump discharge

connection, or by filling the suction pipework before attaching to the pump, then

fill the pump.

5. Starting

a) Switch on power to the pump which will now be operational.

b) Carefully check pump and pipework for leaks whilst pump running and stationary

before leaving the installation unattended.

For Further Technical Support

Note: When pumps are installed in another manufacturers original equipment, please

contact the manufacturer for advice.

Phone the Stuart Turner PumpAssist team on 0844 98 000 97. Our staff are trained to

help and advise you over the phone or arrange for a service engineer to call.

INLET

OUTLET

PRIMING PLUG

PRIMING PLUG

Fig. 7