MAHLE RTI NTF-15 User Manual

Page 8

Page 6 of 8

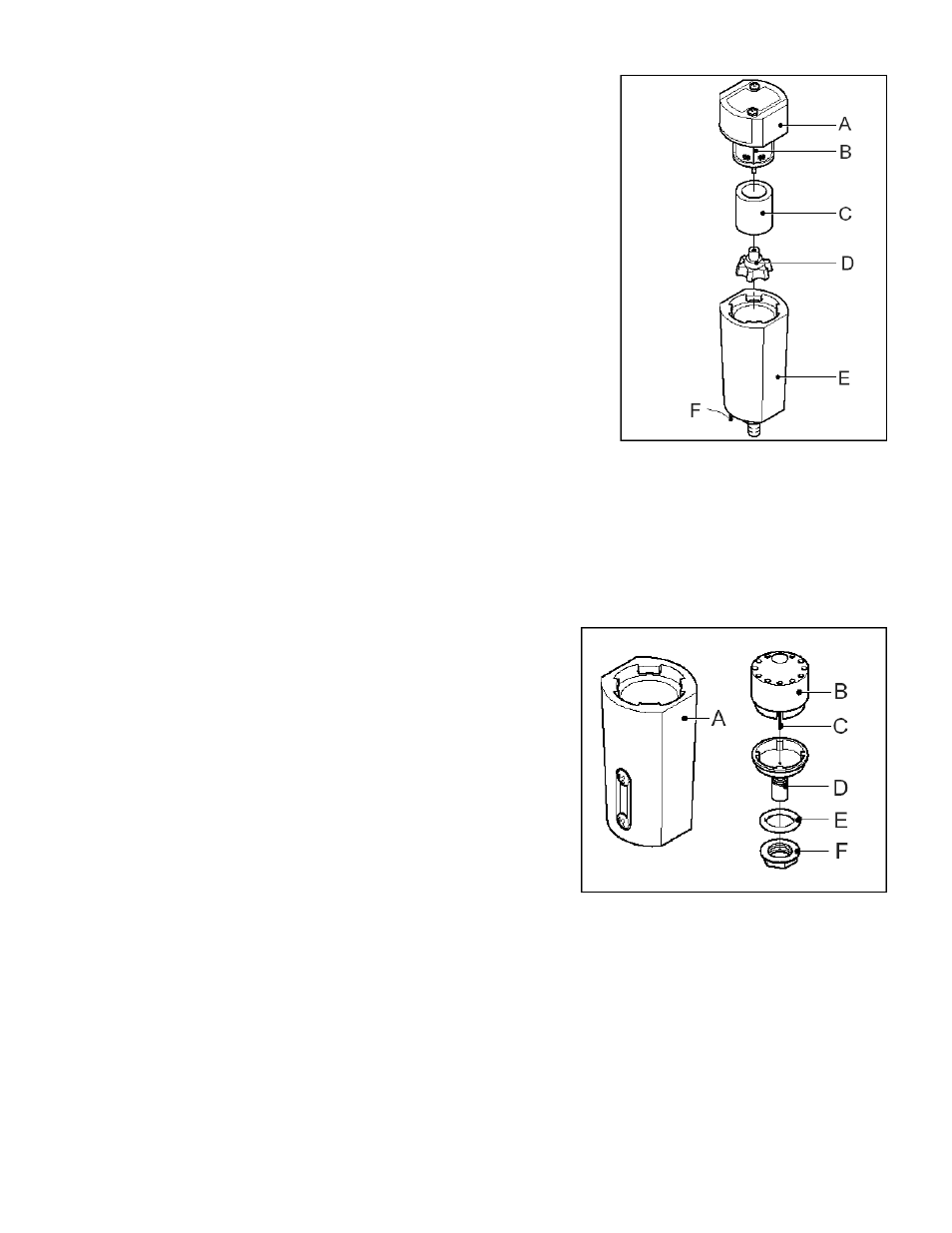

Replace Filter Element

Turn off the air supply.

Let the system depressurize until the pressure gauge reads 0 psi.

Unscrew the bleed screw (F) slowly to ensure that the filter is depressurized.

Turn the filter bowl (E) counter- clockwise and pull the bowl from the filter

housing (A).

Unscrew the blue knob (D).

Remove the old filter element (C).

Clean the sieve (B) and the filter house, if necessary.

Install a new filter element (C).

Assemble the parts in the reverse order.

Note: A periodic check of the automatic drains is neccesary to ensure the membrane life. To verify float is

functioning correctly, open the filter bowl by turning one quarter turn counter-clockwise. Inspect for water or

oil, an inactive float will be submerged, an active float will not. If float is found to be inactive follow cleaning

procedure below or if necesary replace with part number 026-80386-00.

Clean Automatic Drain

Open the filter by turning the bowl one quarter turn counter-clockwise.

Unscrew the nut (F).

Remove the drain unit (B-E) from the filter bowl (A).

Remove the O-ring (E).

Carefully pull the floating house (B) from the seat (D). Do not bend the

needle (C).

Clean the parts with soap and water. Make sure that the needle bore is

open and clean.

Assemble the parts in the opposite direction. Make sure that the parts

are dry before reassembly.

Automatic Pressure Switch Setting

The automatic pressure switch found in the is factory pre-set to shut off shop air consumption at 120 psi. This switch

will then automatically reset when the N

2

Pressure inside the tank drops by approximately 25 psi.

If your application requires an inlet pressure of 100 - 119 psi an adjustment to the automatic pressure switch is

possible. Please contact RTI Technical Support at 800-468-2321 extention 259 for further details.