Process parameters, Clean shop air – proper flow & pressure, Important – MAHLE RTI NTF-515 (Rev A) User Manual

Page 5

PROCESS PARAMETERS

The nitrogen production depends on these parameters:

Flow rate

The lower the flow rate of compressed air through the hollow fiber membrane, the

more oxygen can permeate through the membrane wall. As a result, the nitrogen

produced at the outlet will have a higher purity. Nitrogen purity can be adjusted with

the flow control valve.

Temperature

The NTF-515 operates at a temperature between 40-110

0

F (70-80

0

F optimally). If

the temperature increases, the pressurized air consumption will also increase. Do

not place the system in a room where the temperature may rise unnecessarily high.

Membrane

pressure

Allow enough piping between the compressor exit and the NTF-515 inlet so that the

hot compressed gas has time to cool within the specifications listed in this manual.

A higher membrane pressure will increase the capacity (i.e. nitrogen output) of the

NTF-515. Pressure also enables operation of the pneumatic pressure switch.

External

pressure

There must be atmospheric pressure at the outlet. The capacity and the purity of

the nitrogen gas decreases strongly if the vent pressure exceeds the atmospheric

pressure.

CLEAN SHOP AIR – PROPER FLOW & PRESSURE

Many shop air supplies have an oiler installed to provide lubrication for air tools. The life of the filters in

the NTF-515 will be increased if the shop air supply is free from moisture and oil.

Recommendation - install a separate air line without an oiler to connect to the NTF-515. If this is not

practical, consider installing a separate pre-filter before connecting the NTF-515 to limit potential

contamination to the NTF-515 filters.

Also, ensure the shop air supply meets the pressure and flow ratings stated in the NTF-515 Operation

Manual for maximum nitrogen generation.

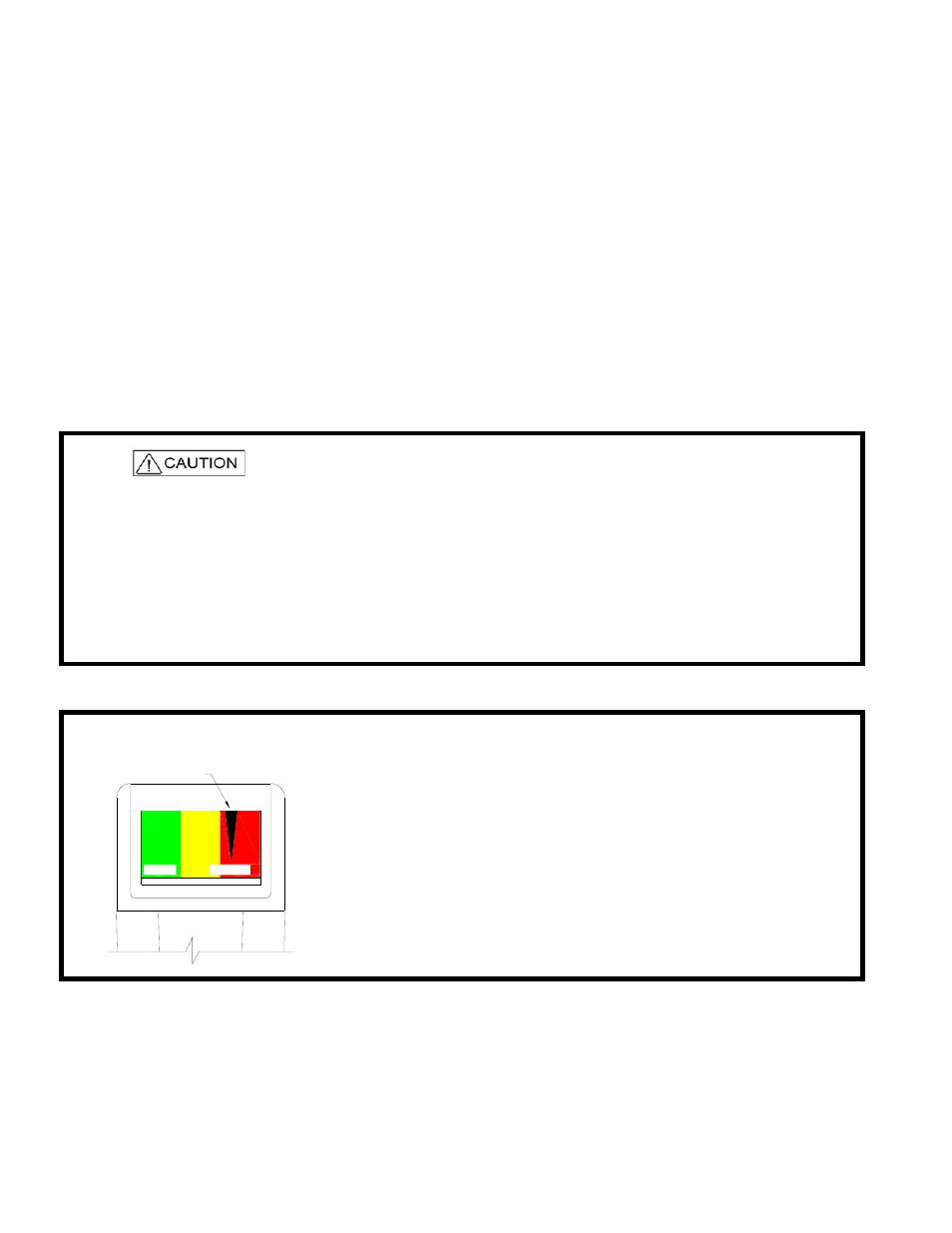

CLEAN

CHANGE

Indicator

5

6

0

-8

0

3

7

4

-0

0

... IMPORTANT ...

The condition of the Filter Element (mounted on rear of unit) can

only be checked when shop air is connected to the unit and it is in

the FILL TIRE mode of operation with Nitrogen being generated

and filling the tank. It may be necessary to press the trigger on the

fill wand to cause the tank filling. At all other times the Indicator will

not be visible.

The Filter Element must be changed when the indicator moves into

the CHANGE area and at least annually to protect the membrane

warranty.

5