Important, Maintenance – MAHLE RTI NTF-230 User Manual

Page 10

9

MAINTENANCE

... IMPORTANT ...

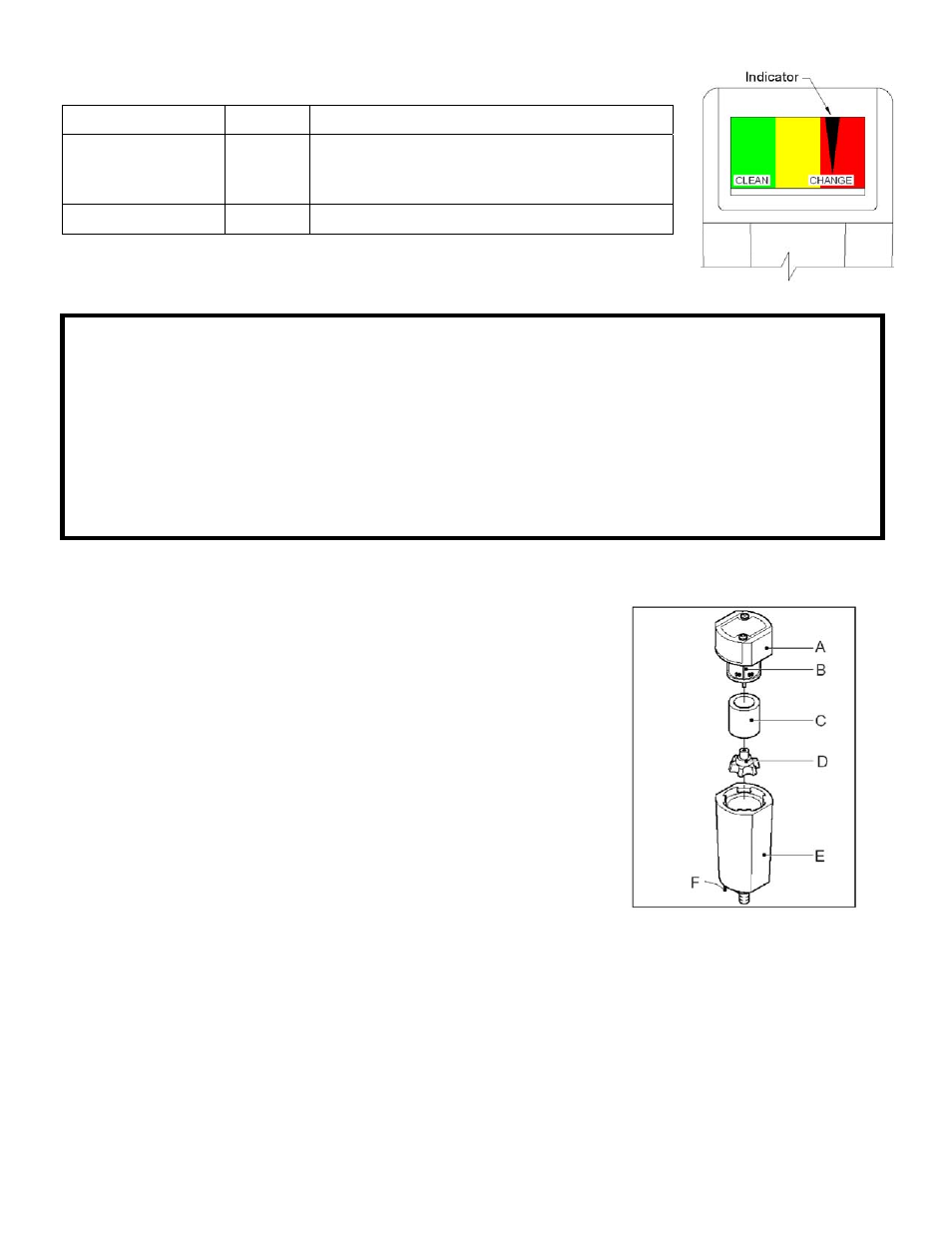

The condition of the Filter Element (mounted inside NTF-230) can only be checked when shop air

is connected to the unit and it is in the FILL TIRE mode of operation with Nitrogen being generated

and filling the tank. If this is not done, the Indicator will not be visible.

The Filter Elements must be changed when the indicator moves into the CHANGE area or annually

to protect the membrane warranty.

REPLACE FILTER ELEMENT

Disconnect

the

air

supply.

Let the system depressurize until the air pressure gauge reads 0 PSI.

Unscrew the bleed screw (F) slowly to ensure that the filter is

depressurized.

Turn the filter bowl (E) counter- clockwise one eighth of a turn and pull

the filter bowl down from the filter housing (A).

Unscrew the blue knob (D).

Remove the old filter element (C).

Clean the sieve (B) and the filter house, if necessary.

Install a new filter element (C).

Assemble the parts in the reverse order.

Note: A periodic check of the automatic drains is necessary to ensure maximum membrane life. To

verify float is functioning correctly, open the filter bowl by turning one quarter turn counter-

clockwise. Inspect for water or oil, an inactive float will be submerged, an active float will not. If

float is found to be inactive follow clean automatic drain procedure or if necessary replace with

part number 026-80386-00.

Part

Action

Frequency

Filter Element

Replace

Yearly or when indicator on the filter head

moves to the CHANGE area as shown in the

illustration to the right (change all 3 filters).

Automatic Drain

Clean

When required