Mounting methods, Installation locations, External wiring – Yokogawa JUXTA VJU7 User Manual

Page 2: 1 wall mounting, 2 din rail mounting, 3 mounting using a multi-mounting base, 4 using a duct, Warning, Important

2

All Rights Reserved. Copyright © 1999, Yokogawa M&C Corporation

IM 77J01U07-01E

4th Edition Feb. 09, 2007-00

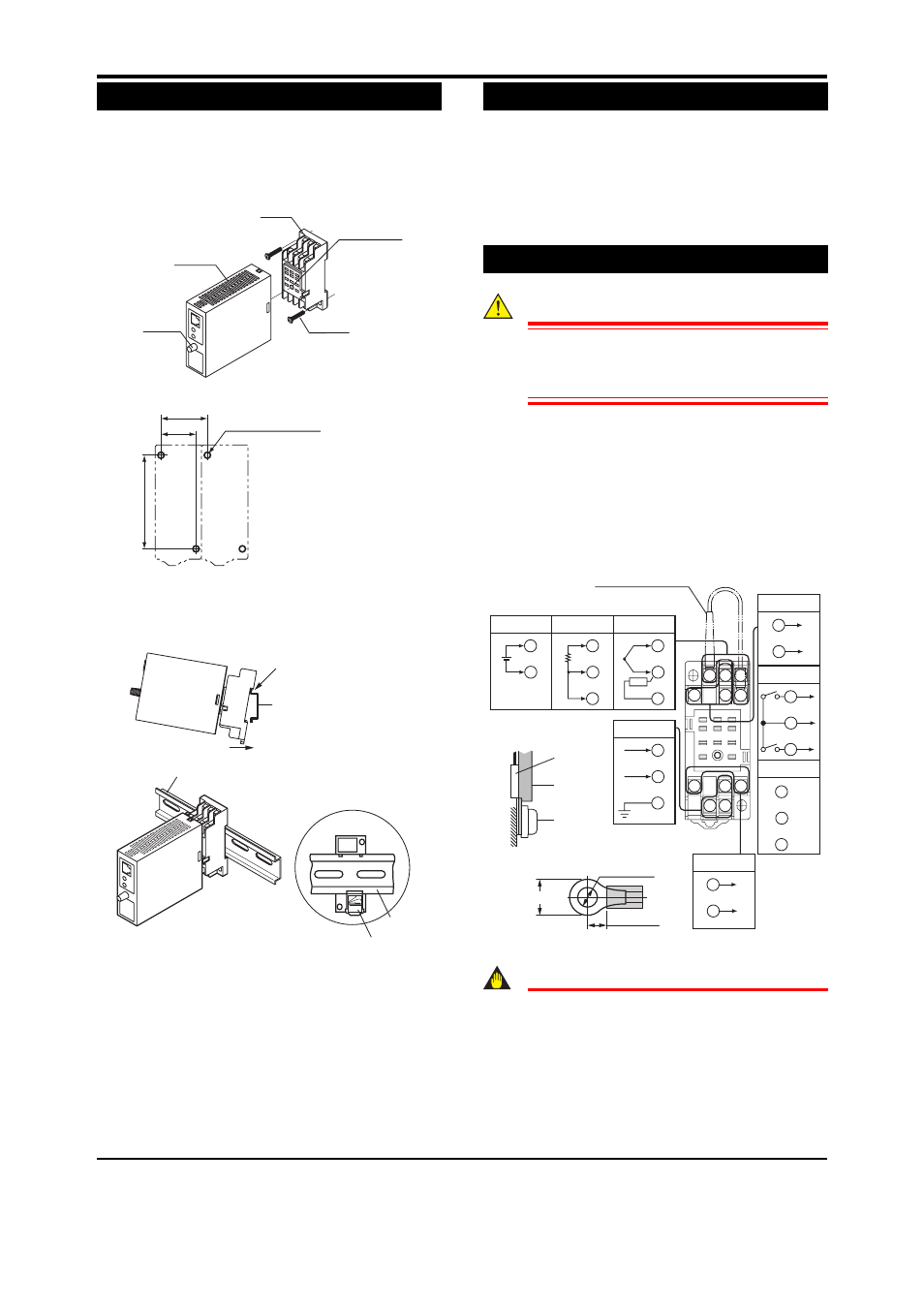

5. MOUNTING METHODS

5.1 Wall Mounting

Loosen the main unit-fixing screw to disconnect the main

unit from the socket. Next, anchor the socket onto the wall

with screws. Then, plug the main unit into the socket and se-

cure the main unit with the main unit-fixing screw.

Main

unit-fixing

screw

Socket

Main unit

Hole for main

unit-fixing screw

Mounting

screws

Unit: mm

29.5 or more

22

±

0.2

59

±

0.3

2-M4 or 2-ø4.5 or more

5.2 DIN Rail Mounting

Locate the VJU7 so that the DIN rail fits into the upper part

of the DIN-rail groove at the rear of the socket, and fasten

the socket using the slide lock at the lower part of the

socket.

DIN rail

Fit into here

Push

DIN rail

(Rear of the socket)

Slide lock

DIN rail

5.3 Mounting Using a Multi-mounting Base

For mounting using a multi-mounting base, see the user’s

manual for VJCE (VJ Mounting Base).

5.4 Using a Duct

Wiring duct should be installed at least 30 mm away from

the top and bottom faces of the main unit.

6.

INSTALLATION LOCATIONS

•

Avoid the following environments for installation locations:

Areas with vibrations, corrosive gases, dust, water, oil,

solvents, direct sunlight, radiation, a strong electric field,

and/or a strong magnetic field.

•

If there is any risk of a surge being induced into the power

line and/or signal lines due to lightning or other factors, a

dedicated lightning arrester should be used as protection

for both the product and a field-installed device.

7.

EXTERNAL WIRING

WARNING

To avoid the risk of an electric shock, turn off the

power supply and use a tester or similar device to

ensure that no power is supplied to a cable to be

connected, before carring out wiring work.

Wiring should be connected to the terminals on the socket of the

VJU7. The terminals for external connections are of M3 screws.

Use crimp-on lugs for connections to the terminals.

•

Be sure to use a compensating lead wire for thermo-

couple input.

Recommended cables: A nominal cross-sectional area

of 0.5 mm

2

or thicker for output signal cable, a nominal

cross-sectional area of 1.25 mm

2

or thicker for power

cable and shielded twisted-pair cable (AWG24) for com-

munication cable.

10

11

3

2

1

4

5

6

7

8

9

3

1

4

5

2

6

3

1

3

1

4

A

B

B

Thermocouple

RTD

mV

RJC

Input signal (Input type can be changed.)

11

10

8

GND

Power supply

9

7

Analog output

Ouptut-1

signal

5

2

Analog output

Output-2 signal

ALM1

ALM2

COM

Alarm output

5

2

6

COM

RS-485

RJC sensor

(for thermocouple input)

(NO)

(NO)

+

–

+

–

+

–

+

–

L+

N–

B+

A–

Signal

line

RJC

sensor

Terminal

screw

Recommended crimp-on lug size

(Unit: mm)

5.5 or more

ø3.2 to 3.5

Make the wiring resistance

of RTD input terminals 1

and 3 the same.

5.5 or less

IMPORTANT

●

Connect the RJC sensor at the correct position

as shown above. Otherwise tempratures cannot

be measured carrectly.

●

Conect the RJC sensor so that it overlaps the in-

put signal line.

●

Handle the RJC sensor lead wire care to prevent

disconnection.