6 mowing on varying terrain, 8 changing the speed/sensitivity adjustment, 9 how to perform the tracking adjustment – Wright Serial # 63495 and higher User Manual

Page 23: 7 how to adjust neutral

19

WARNING

5.6 Mowing on Varying Terrain

See the

Safety Instructions

section of this manual, especially the parts on:

•

Initial Operating Safety Guidelines

•

Operation On Slopes

•

Operation In Reverse

•

Operation In Forward Direction

•

Operation During Zero-Radius Turns

5.7 How to Adjust Neutral

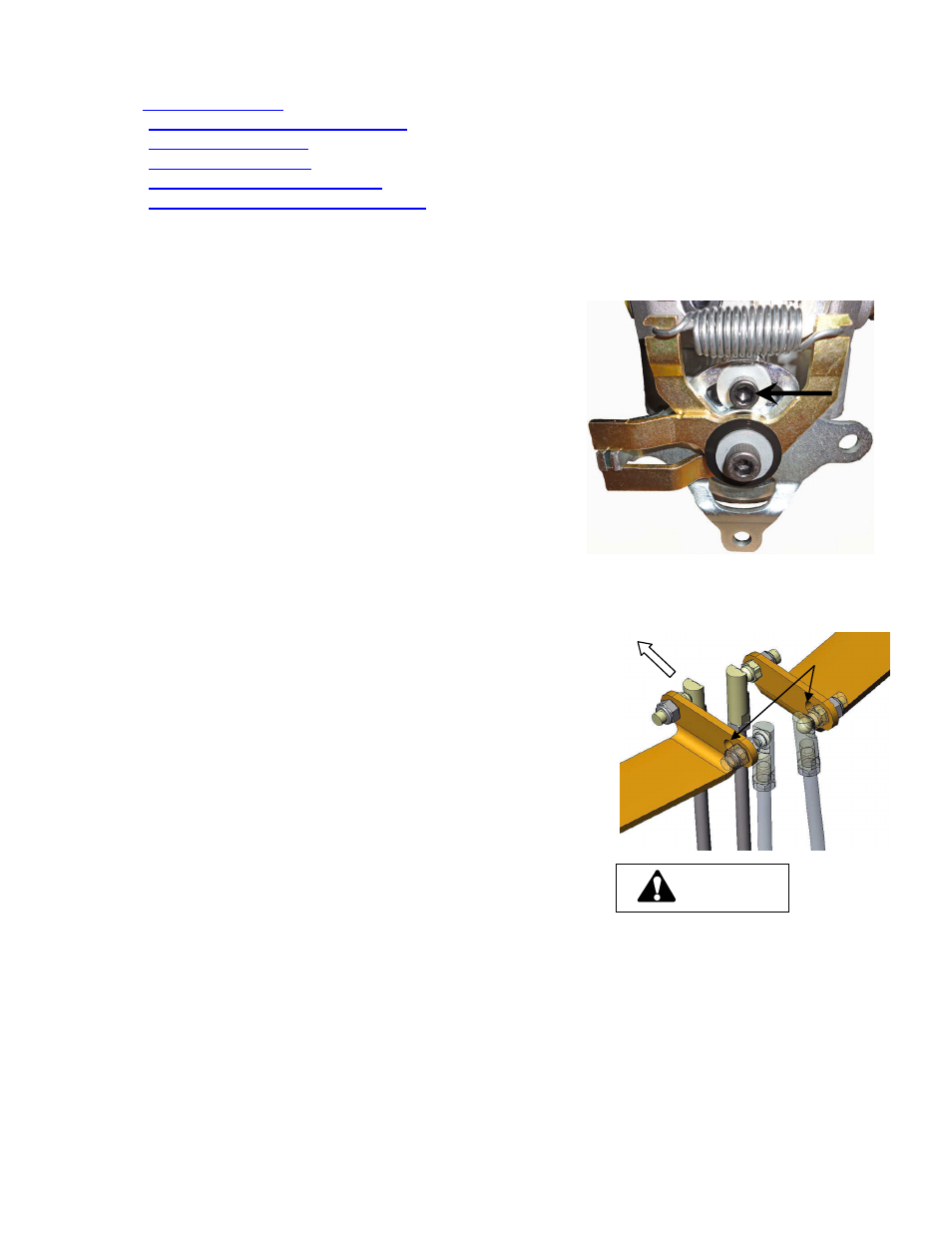

Neutral refers to the mower movement when the engine is set to full throttle, parking brake is off, and the

control levers are in the neutral position. The mower should not move forward or backward during this time.

If the mower is moving forward or rearward, the neutral setting

must be adjusted. The hydraulic pump has a Return-to-Neutral

(RTN) device built into the linkage of the pump. Before adjusting

neutral, it is necessary to lift the rear drive wheels off the ground

using a jack and stands. To make the adjustment, loosen the ¼”

Allen bolt (A) and rotate the RTN device on the pump

corresponding to the wheel that needs adjustment. If the right

wheel turns in the neutral position, then the right pump RTN

needs to be adjusted. The RTN mechanism should be rotated

until the neutral position is found and then retighten the ¼” allen

bolt. Use care not to over tighten the allen bolt. Repeat the

procedure on the other pump if necessary.

5.8 Changing the Speed/Sensitivity Adjustment

The controls are initially set with the Speed/Sensitivity Adjustment in the faster, more sensitive position. If an

operator is not completely familiar with the mower operation the operator may desire to decrease the ground

speed. The slower setting has a corresponding decrease in the

sensitivity of the controls. In other words, a given amount of

movement of the control levers will cause about a 25-30% change in

the ground speed making the controls less sensitive. After stopping

the engine, the adjustment is made by removing rod ends from the

current holes in the control system torsion bar and reinstalling them

into the alternate holes. The holes farthest from the operator position

are for the slower, less sensitive setting and the holes closest to the

operators position are the faster, more sensitive setting. You must

then perform the Tracking Adjustment described below.

5.9 How to Perform the Tracking Adjustment

First ensure that the tire pressure is equal on both rear drive tires (18-22 psi). Drive the mower on a level

parking lot with the engine at full throttle. Check that the mower drives in a straight line when both hand

controls are held to the full speed position. If not, park the mower and stop the engine. The adjustment is

made by loosening the jam-nuts on the control rods (this may need to be done to one or both control rods)

and adjusting the control rods. Once the jam-nuts are loosened at the top and bottom of the control rod

proceed to turning the control rod clockwise or counter-clockwise. Shortening the control rod will increase

the speed of the forward movement of the mower on that side. Lengthening the control rod will slow the

forward movement of the mower on that side.

In the “faster” Speed/Sensitivity setting (this is the factory setting) neither rod should be lengthened so much

that at full speed it pulls the

pump control lever (on the sides of the pumps) against the internal pump stop.

Therefore, to reach the maximum capable speed, the rods should be lengthened one turn at a time until you

A

Front

Slow setting