English, Hot cold – Pfister 048-CNFC User Manual

Page 4

4

Thank you for purchasing this Price Pfister product. All Price

Pfister products are carefully engineered, and factory tested

to provide long trouble-free use under normal conditions.

This product is easy to install using basic tools and our easy

to follow illustrated instructions. If you have any questions

regarding this product, see info on previous page.

1 BEFORE PROCEEDING

WARNING: Read all the instructions completely before

proceeding. Price Pfister recommends calling a professional

if you are uncertain about installing this product!

This product should be installed in accordance with all local

and state plumbing and building codes.

2 SHUT OFF WATER SUPPLY

Locate water supply inlets and shut off the water supply

valves. These are usually found under the sink or near the

water meter. If you are replacing an existing faucet, remove

the old faucet from the sink and clean the sink surface

thoroughly.

3 ASSEMBLY INSTRUCTIONS

If operating pressures exceed 5 BAR (75 PSI), the use of

a pressure reducer is recommended. Before proceeding

with the assembling, we advise to clean the hot and cold

water tubes, in order to avoid build-up of dirt that could

compromise the functioning of the faucet.

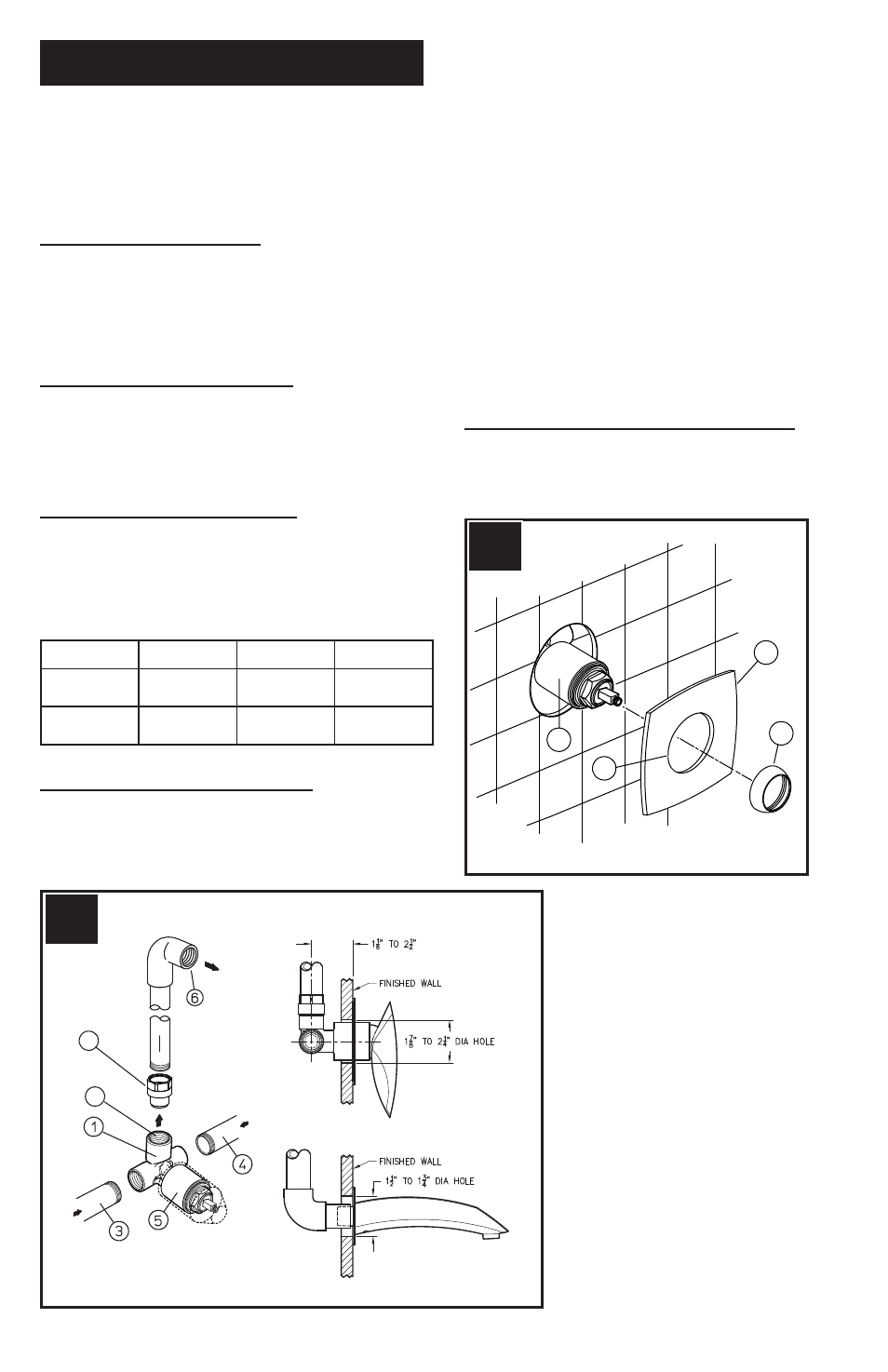

4 VALVE INSTALLATION (Fig.A)

Place the Valve Body (1) into the wall, with the Outlet (2)

facing the up. Body inlets (3&4) and outlet (2) are designed

to accommodate 1/2-14 NPT pipe. Connect the Hot Water

Supply (3) to the Left Inlet and the Cold Water Supply (4) to

the Right Inlet. Connect pipe from Supply Valve Outlet (2)

to Spout Hole. Connect Pipe Elbow (6) and Pipe Nipple (7)

(not included) to end of the pipe as shown.

The Depth is measured from center of Valve Body to

finished wall surface is 1 1/8” to 2 1/2”. Valve Hole on wall

is to be 1 7/8” to 2 1/4” Dia. Spout Hole on wall is to be

1 1/2” to 1 3/4” Dia.

WARNING Iron Pipe Connections: When attaching

threaded fittings, use thread sealant or PTFE Plumber’s

tape according to manufacturer’s instructions..

CAUTION: When using iron pipes, it is not recommended

to reduce outlet pipe diameter.

CAUTION: For Copper Sweat joints, it is important to

remove Valve Cartridge and other Plastic Components

from the Valve Body before soldering. Use copper pipe

adapters (not furnished) in this type of installation.

5 TRIM FLANGE ATTACHMENT (Fig.B)

Position Trim Flange (1) with Rubber Gasket (2) onto the

Valve Body (3) and slide flush to wall finish. Secure by

screwing Dome Cap (4) onto Valve Body (3).

ENGLISH

7

2

A

HOT

COLD

B

1

2

3

4

Supply

Suggested

Maximum

Minimum

Hot Water

Temperature

65 Cº (150ºF)

80 Cº (175ºF)

15 Cº (60ºF)

Operating

Pressure

3 BAR (44PSI)

5 BAR (73PSI)

0.5 BAR (7PSI)