PCT Engineered Electron Beam Technology for Converting Applications User Manual

Page 7

ELECTRON

BEAM

EMBOSSED

DRUM

COATER

REWIND

UNWIND

EMBOSSED

PATTERN

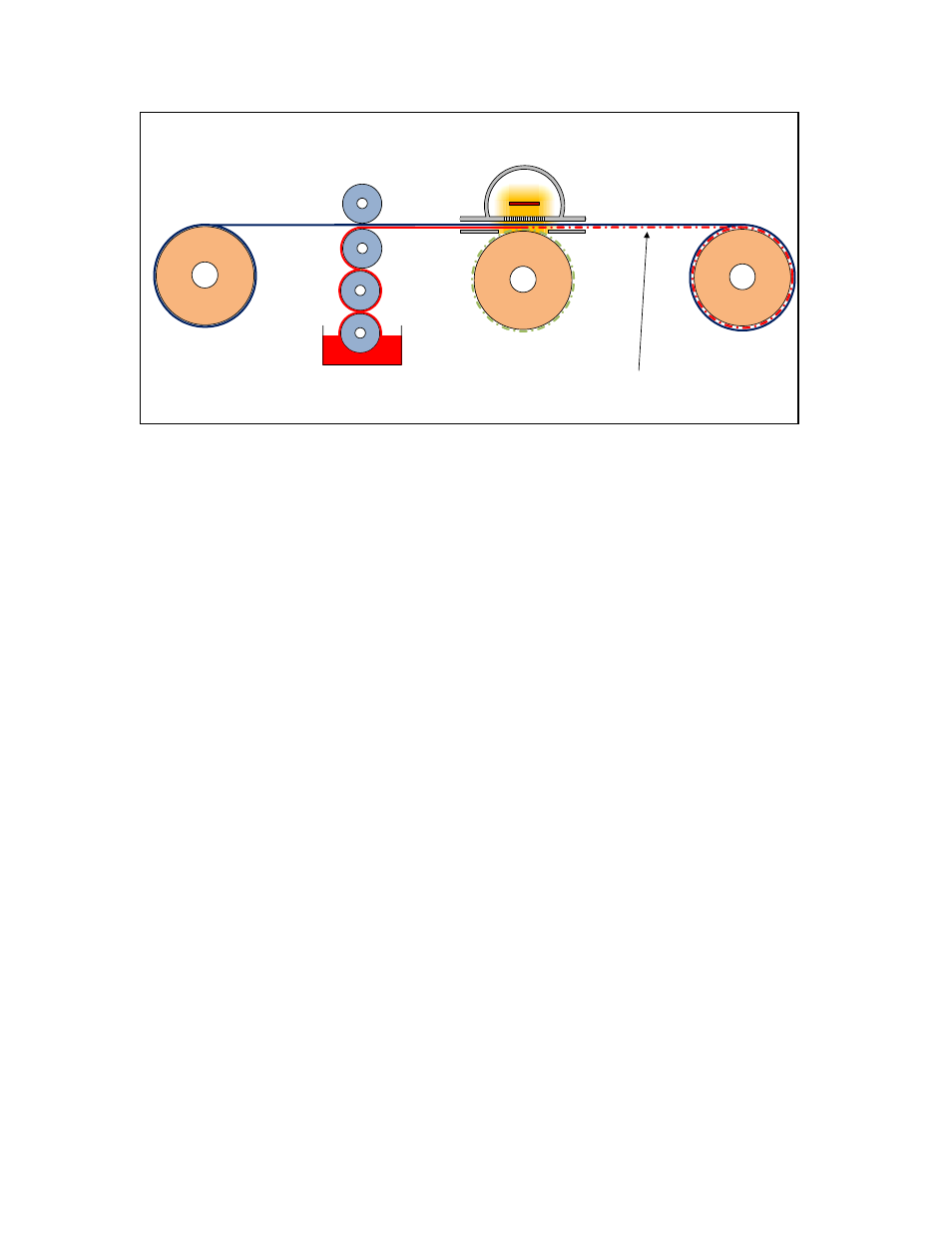

Figure 7. Backside Embossing

Backside Embossing

The process of EB backside embossing is shown in Figure 7. Many different types of

substrates including paper can be used. The voltage of the EB equipment should be

appropriate for penetration through the substrate. The pattern defined by the embossed

drum can produce almost any feature size ranging from on the order of 1 micron to more

than several inches. Pattern reproduction using EB technology is known to be more

accurate than thermal embossing. The resulting embossed coatings are highly

crosslinked which results in excellent chemical and thermal resistance properties.

Manufacturing of casting papers is an established application of this technology. The

casting papers are used for the subsequent production of textured vinyl and urethane

based films that are found in many consumer products. Patterns defined by EB casting

can also be used to produce wide array of unique tactile and optical effects including

reflective materials and lenticular or holographic images.