PCT Engineered Electron Beam Technology for Converting Applications User Manual

Page 4

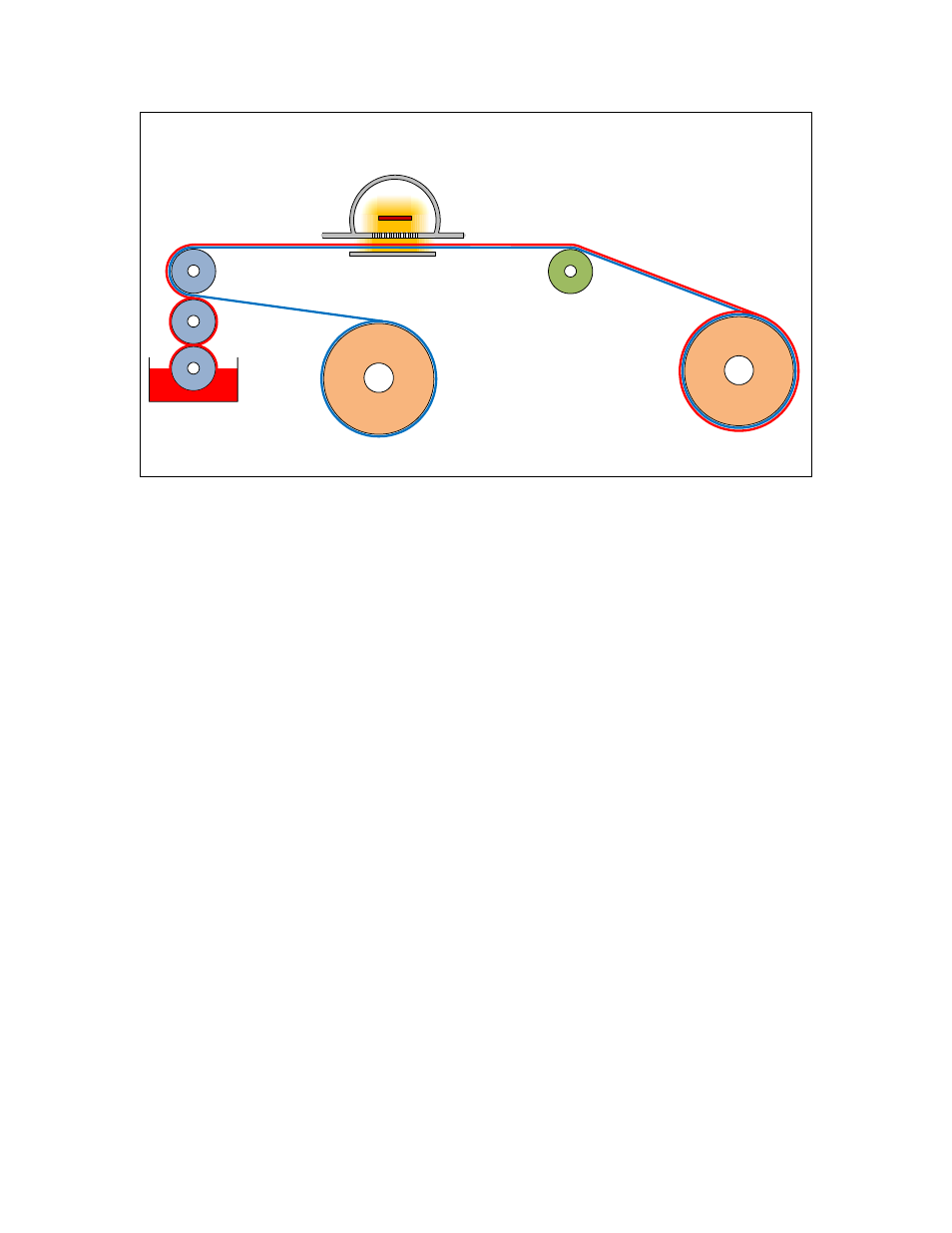

ELECTRON

BEAM

UNWIND

COATER

REWIND

Figure 4. Direct Coating

Direct Coating

There is a large variety of functional coatings that may be cured using EB technology.

EB curable release coatings are well known. They include premium silicone release

coatings used in the manufacture of release liners for PSA’s. Silicone and non-silicone

release coatings may also be produced for use in various industrial applications.

EB curable coatings can be used together with vacuum metallization processes.

Premetallization primers may be used to provide a uniform receptive surface for

subsequent metallization. EB coatings over the metalized surface can enhance or

preserve barrier properties of the film. EB can also provide corrosion protection for the

metal layer under some end-use conditions.

The use of EB protective coatings is well known. An example is EB coatings for

decorative paper that is subsequently laminated to furniture or countertops. The

crosslinked nature of the EB coating provides the desired resistance to damage by

staining and scratching.

EB excels at curing pigmented and filled coatings. The ability of EB to penetrate opaque

materials allows curing of coatings that can not be cured using UV technology. Examples

include magnetic media and abrasive binders. Curing of pigmented and filled coatings

may be achieved by new generation lower voltage (70 to 125 kV) or higher voltage (150

to 300 kV) equipment depending on the thickness and density of the coating layer.