Rpb12 filter/regulator accessories, Technical specifications – rpb12, Caution – Ross Controls STAINLESS STEEL SERIES 15 User Manual

Page 4

Printed in the U.S.A. – Rev. 05/12

© 2012, ROSS CONTROLS. All Rights Reserved.

Form NPS023

WARRANTY and CAUTIONS

Standard ROSS warranty and cautions apply, available upon request or at

www.rosscontrols.com.

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

ROSS ASIA K.K.

Japan

Fax: 81-427-78-7256

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

ROSS CONTROLS INDIA Pvt. Ltd.

India

Fax: 91-44-2625-8730

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

ROSS CONTROLS

(CHINA) Ltd.

China

Fax: 86-21-6915-7960

rosscontrolschina.com

ROSS CONTROLS

U.S.A.

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

www.rosscontrols.com

0

20

30

50

10

40

60

70

90

80

100

0

10

20

30

40

50

60

70

80

90

100

Pressure Dr

op - PSIG

0

0

5

10

15

20

25

30

35

40

45

Flow - SCFM

Flow - dm /s

Pressure Dr

op - bar

3

n

1

2

3

4

5

6

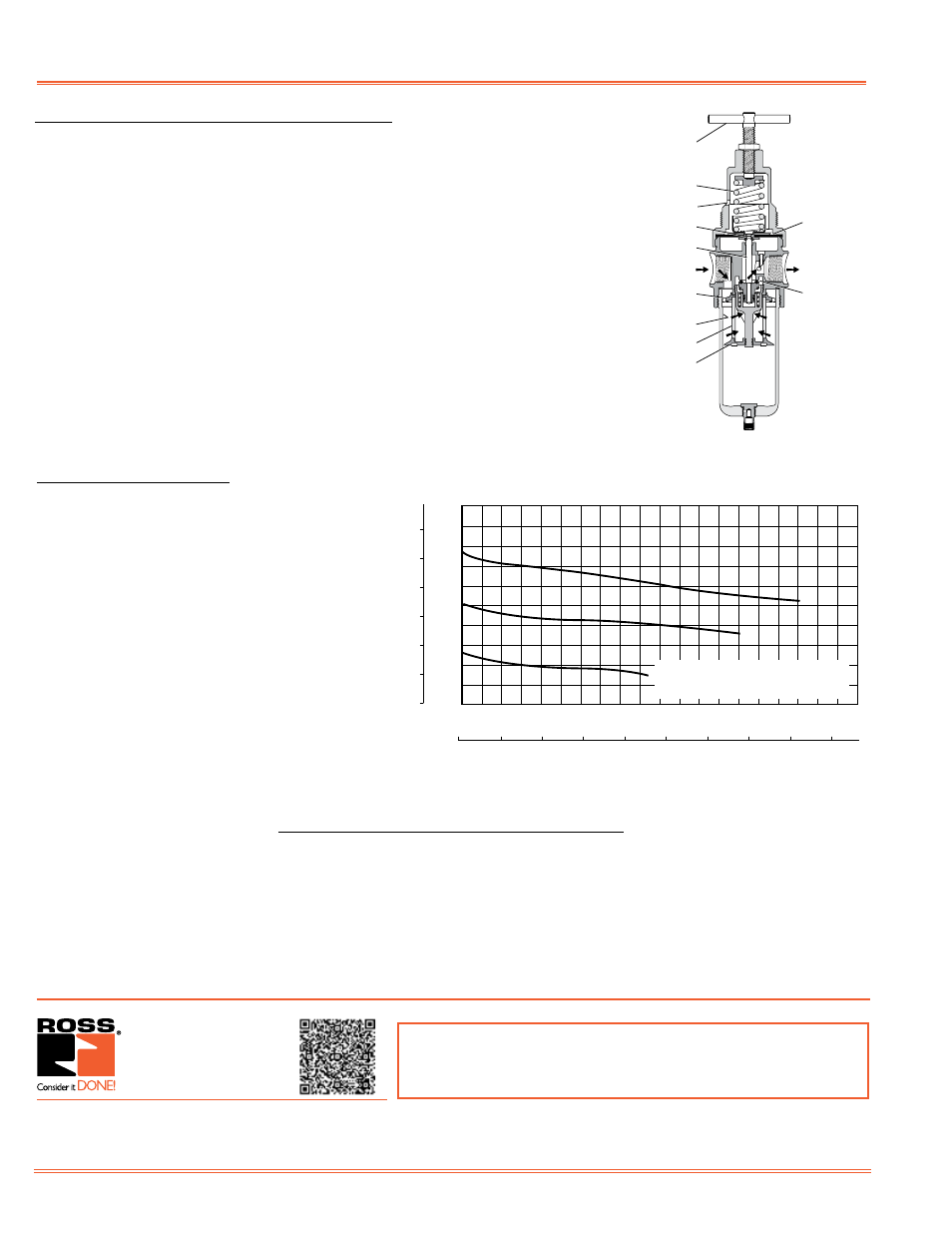

Flow Characteristics

RPB12

1/2 Inch Ports

100 PSIG (6.9 bar Primary Pressure

Gauge (Stainless) –160 PSIG (0 to 1100 kPa), 2" Face RK4520N14160SS

Panel Mount Bracket (Stainless) ............................. R10Y57-SS

Panel Mount Nut – Stainless ............................... R10X51-SS

– Plastic...................................... R10X51-P

Overview of RPB12 Regulator Operation

Technical Information

Turning the adjusting knob / T-Handle

(A) clockwise applies a load to control spring (B) which

forces diaphragm

(C) and valve poppet assembly (D) to move downward allowing filtered

air to flow through the seat area

(E) created between thepoppet assembly and the seat.

“First stage filtration”.

Air pressure supplied to the inlet port is directed through deflector plate

(F) causing a swirling

centrifugal action forcing liquids and coarse particles to the inner bowl wall

(G) and down

below the lower baffle

(H) to the quiet zone. After liquids and large particles are removed in

the first stage of filtration

“second stage filtration” occurs as air flows through element (J)

where smaller particles are filtered out and retained. The air flow now passes through seat

area

(E) to the outlet port of the unit. Pressure in the downstream line is sensed below the

diaphragm

(C) and offsets the load of spring (B). When downstream pressure reaches the

set-point, poppet valve assembly

(D) and diaphragm (C) move upward closing seat area (E).

Should downstream pressure exceed the desired regulated pressure, the excess pressure will

cause the diaphragm

(C) to move upward opening vent hole (K) venting the excess pressure

to atmosphere through the hole in the bonnet

(L). (This occurs in the standard relieving type

filter/regulators only.)

CAUTION:

REGULATOR PRESSURE ADJUSTMENT –

The working range of knob adjustment is designed

to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also

possible because the knob is not a limiting device.

This is a common characteristic of most industrial

regulators, and limiting devices may be obtained

only by special design.

For best performance, regulated pressure should

always be set by increasing the pressure up to the

desired setting.

F

G

J

B

L

D

K

A

H

C

E

RPB12 Filter/Regulator Accessories

Technical Specifications – RPB12