Overview of dm, Series e double valve function – Ross Controls CATEGORY 3 - 3_2 VALVES SERIES DM1 E User Manual

Page 2

Overview of DM

1

Series E Double Valve Function

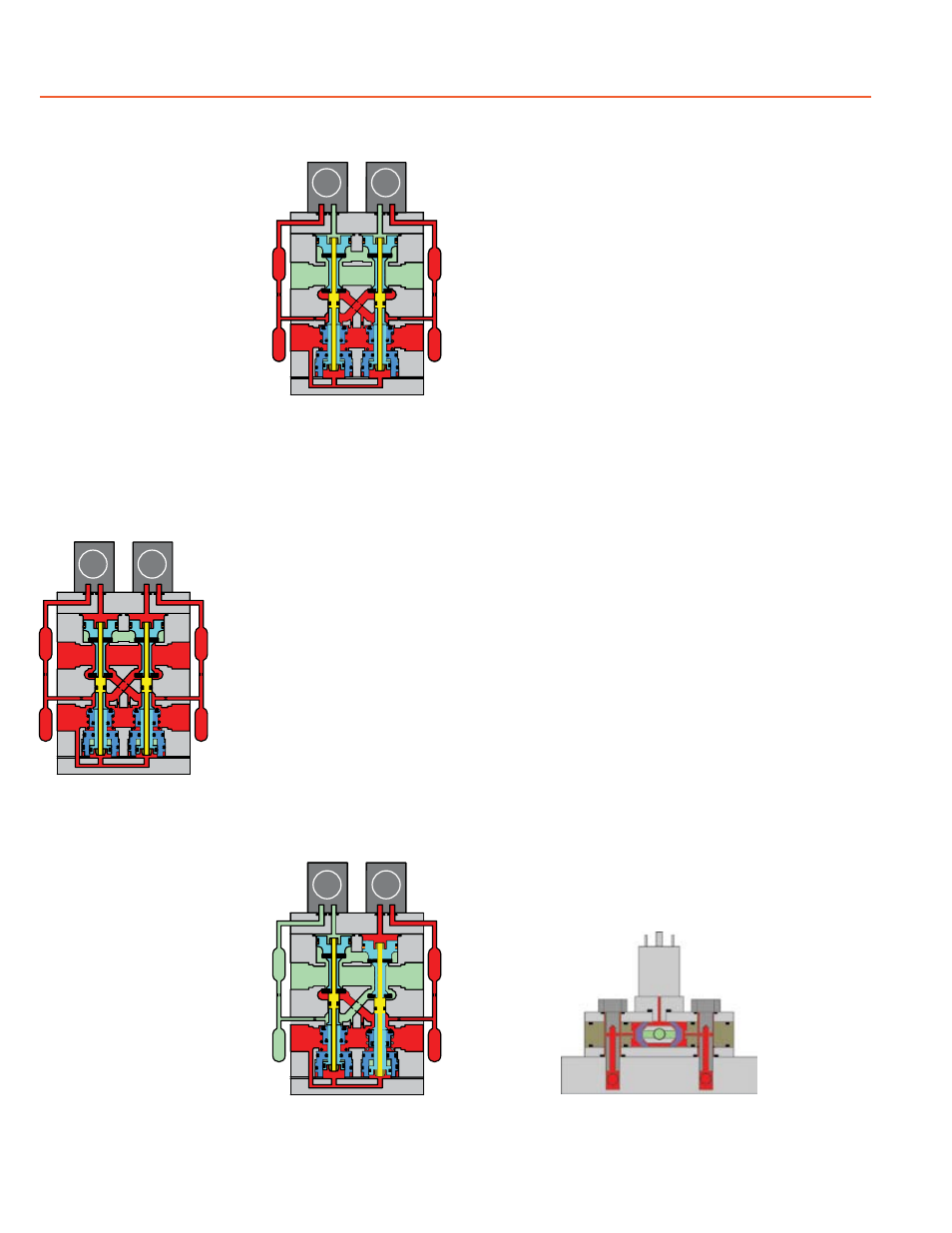

Valve de-actuated

(ready-to-run):

The flow of inlet air pressure

into the crossover passages

from the inlet chamber is

restricted by orifices that allow

air pressure to bypass the lower

inlet poppets. Flow is sufficient

to quickly pressurize the pilot

supply/timing chambers on both

sides A and B. The upper inlet

poppets prevent air flow from

the crossover passages into the

outlet chamber. Air pressure

acting on the inlet poppets and

return pistons securely hold

the valve elements in the de-

actuated position. (Internal air

passages shown out of the valve

body for clarity.)

Valve actuated:

Energizing the pilot solenoids

simultaneously applies pressure

to both pistons, forcing the

internal parts to move to their

actuated position, where inlet

air flow to outlet is open and

both exhaust poppets are

closed. The outlet is then quickly

pressurized, and pressure in

the inlet, crossovers, outlet, and

timing chambers are quickly

equalized. De-energizing the

main solenoids causes the valve

elements to return to the ready-

to-run (de-actuated) position.

Asynchronous operation:

If the valve elements operate

in a sufficiently asynchronous

manner on ACTUATION, the

valve will shift into a position

where one crossover and its

related timing chambers will

be exhausted, and the other

crossover and its related timing

chambers will be pressurized.

In the illustration, side B is in the

de-actuated position, but has

no pilot air available to actuate

with and has full pressure on its

upper and lower inlet poppets and return piston to hold it in

place. Inlet air flow on side B into its crossover is restricted

and flows through the open upper inlet poppet on side A,

through the outlet into the the exhaust port, and from the

exhaust port to atmosphere. Residual pressure in the outlet

is less than 1% of inlet pressure.

Once the main solenoids are de-energized, actuating pressure

is removed from the top of the main pistons and then the

lower inlet poppet return spring along with inlet air pressure

acting on the side A return piston will push side A back into

the de-actuated position. Inlet air pressurizes the crossovers

and volume chambers. Pressure in the crossovers helps

hold the upper inlet poppets on seat. The valve will then be

in the ready-to-run position. On the next attempt to actuate

normally, if side B is still unable to actuate synchronously

with side A, the same sequence of events described above

will occur again.

WARNING:

If asynchronous operation occurs while DE-ACTUATING,

the pilot supply/timing chambers on one side will still be

exhausted as described above. However, this could be a

temporary situation because the cause of the asynchronous

operation may be able to correct itself allowing the stuck or

slow acting side of the valve to eventually move back into

the de-actuated position. Once the slow or stuck side has

de-actuated, the pilot supply/timing chambers that were

exhausted will then repressurize. If an external monitoring

system is only checking the status indicator periodically this

fault signal could be missed. The machine’s safety system

must be designed to ensure that this does not cause a

hazardous situation.

Status indicator:

The status indicator pressure switch will actuate when the

main valve is operating normally, and will de-actuate when

the main valve operation is sufficiently asynchronous or inlet

pressure is removed. This device is not part of the valve

lock-out function, but, rather, only reports the status of the

main valve.

Status indicator in normal

ready-to-run position.

.004.004

.004

B

A

EXHAUST

OUTLET

INLET

Valve actuated.

B

A

EXHAUST

OUTLET

INLET

Valve ready-to-run.

Valve in restricted outlet

to exhaust state.

B

A

EXHAUST

OUTLET

INLET

ROSS CONTROLS

®