Ramsey Winch HDG-350 RAM LOK User Manual

Page 8

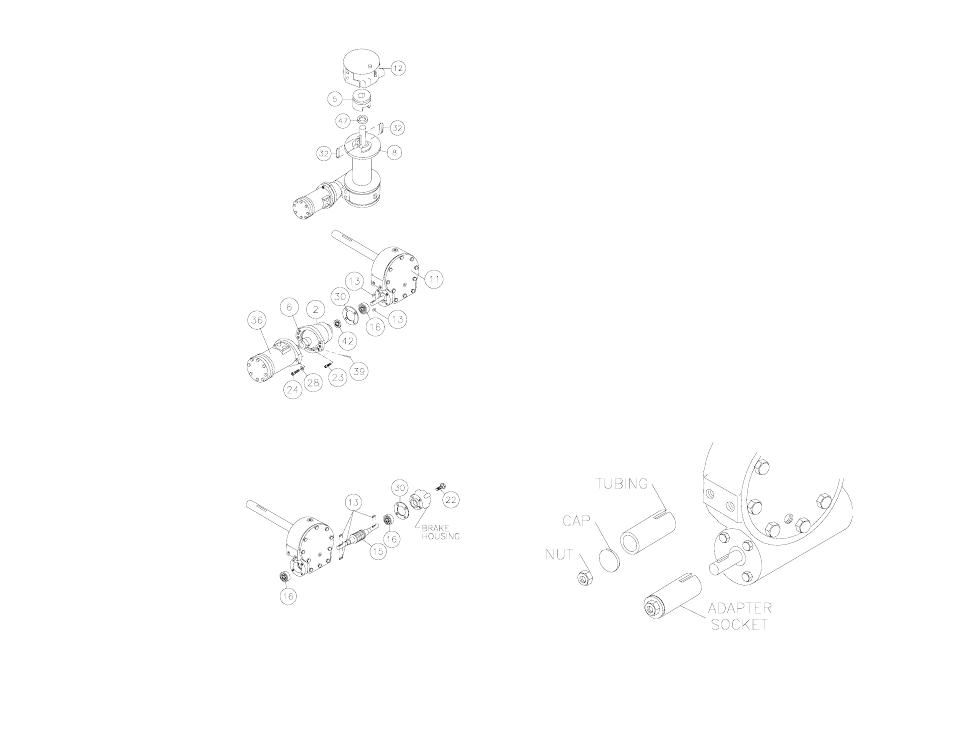

ADJUSTING THE OIL COOLED WORM BRAKE

2. Remove clutch housing #12 and clutch

#5 from winch assembly.

Remove two keys #32 from keyways. A

screwdriver can be used, at notch, to

aid in the removal of keys. Once keys

have been

removed, drum #8 and

thrust washer

#47 can be

removed

from drum shaft.

3. Remove motor #36 and coupling #6 from

adapter #2 by unscrewing two capscrews

#24 with lockwasher #28.

Remove keys #13 from worm shaft.

Unscrew four capscrews #23 and remove

adapter #2 from gear housing. Replace

adapter seal #42 and gasket #30.

4. See page 12 for servicing the oil cooled

brake. Remove brake housing mounting

screws #22 and remove brake with

gasket. Replace gasket #30. Remove

worm #15 and bearings #16 from gear

housing. Use soft hammer to gently tap

input end of worm and drive worm and

bearing from gear housing. Once worm

has been removed from housing,

bearing can be pressed from end of

worm.

Check for signs of wear or damage to

worm

#15 and bearing #16. Replace if

necessary.

The oil-cooled, fully adjustable, automatic brake operates in the worm housing

lubricant, all parts being submerged in oil. When the brake wears to the point that

the load begins to drift, the brake can be adjusted as follows:

1. Loosen the lock nut on the adjusting screw.

2. Tighten the brake by turning the adjusting screw clockwise. CAUTION: Only ¼

turn is usually required to adjust the brake. Over-tightening can cause

overheating, and damage to the brake parts. Tighten the lock nut after

adjustment is completed.

If the brake does not respond to adjustment then a new leaf spring and brake disc is

needed.

A torque wrench can be equipped with a special adapter to fit the input shaft (worm)

of the winch. The adapter can be made by welding a nut to the end of a piece of

tubing as shown below.

After welding the cap and nut to the tubing, slot the tubing as shown. This will allow

the special adapter to slide over the keyway and will then act as a large socket. A

torque wrench can then be used to apply the proper torque. Turn the torque wrench

so that the drum turns in the spool out direction or lowering direction. The torque

rating for the Model HDG-350 should be 9 to 15 ft. lbs. If the torque wrench does not

show the proper value as it turns, then the worm brake adjusting bolt should be

turned clockwise ¼ turn to increase the torque setting. Each time the adjusting bolt

is turned, check the torque reading. Continue this procedure until the proper torque

reading is achieved. Then tighten the lock nut.

11

6