Ramsey Winch HDG-350 LEVER EQUIPPED User Manual

Page 11

9

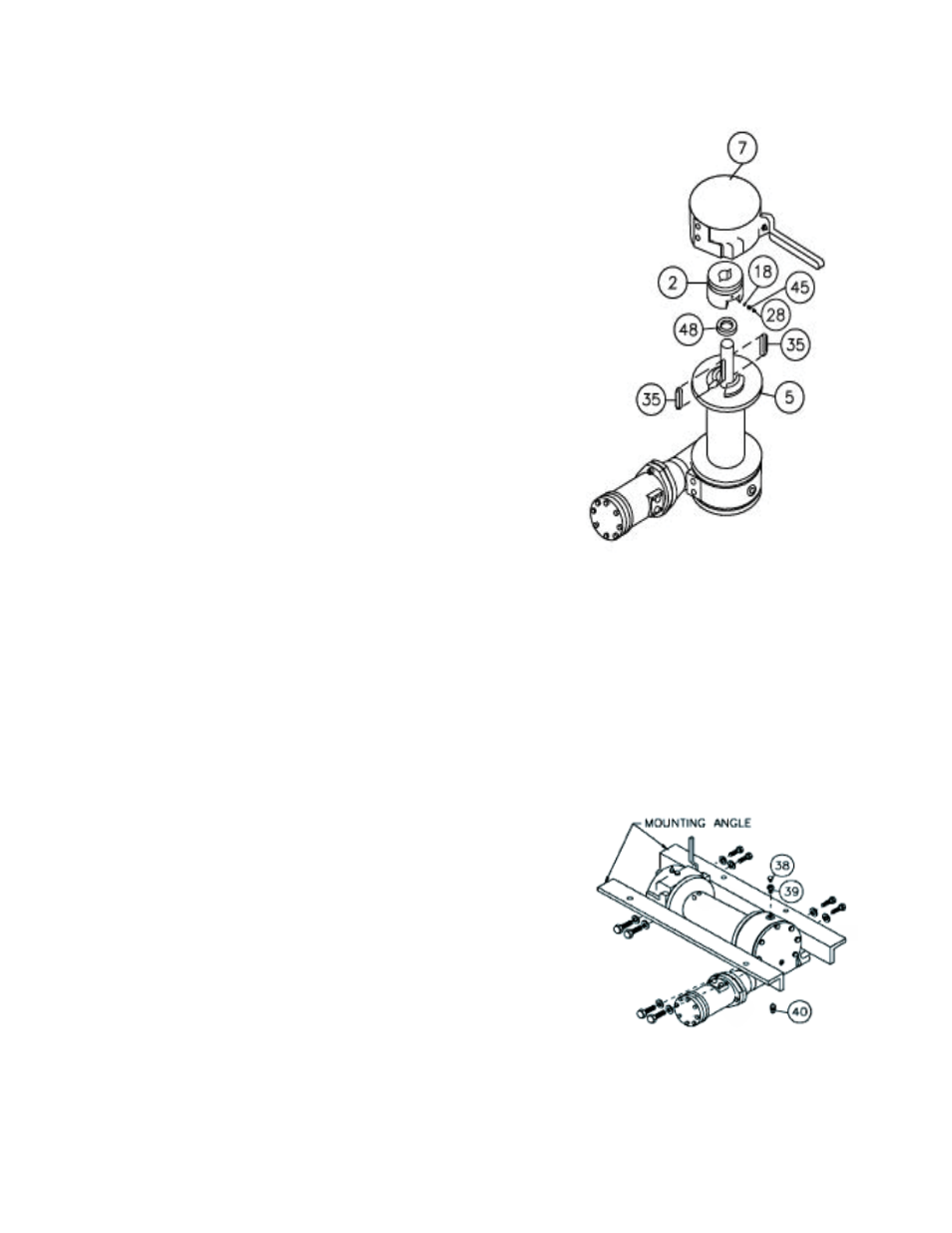

15. Slide spacer #48 over end of drum shaft. Press drum

downward to compress drag brake springs in gear

housing. Insert keys #35 into keyways with sharp

edge of keys pointing outward and notched end of

keys upward. A rubber or brass mallet will be needed

to gently tap keys into position.

Apply grease to keys and end of shaft. Place jaw

clutch #2 over end of shaft and slide jaw clutch over

keys.

NOTE: Be sure that tapped hole on side of jaw clutch

is on same side of shaft as the ball detents. Insert ball

poppet #18, spring #45, & setscrew #28 into tapped

hole of jaw clutch.

If jaw clutch and/or drum shaft have been replaced

two detents for ball must be drilled as follows:

Slide jaw clutch over end of shaft. Align jaws of clutch

with jaws of drum. Use a ¼” dia. drill, using hole in

jaw clutch as a guide, to drill a 1/8” deep detent in

shaft. Slide jaw clutch upward ¾” and drill 2nd detent.

Apply grease to bushing in clutch housing assembly #7.

Set clutch housing onto end of drum shaft. Pull jaw

clutch upward, toward clutch housing, enough to allow

yoke in clutch housing to fit properly in groove around

jaw clutch. Slide clutch housing assembly and jaw

clutch downward into place.

The setscrew should be tightened enough to allow

ball, when placed in ball detents, to sufficiently lock

jaw clutch “IN” and “OUT”.

16. Attach mounting angles using hardware shown.

Torque capscrews to 34 ft. lbs. (46 Nm) each. Insert

plug #40 into bottom of gear housing. Permatex may

be applied to threads to prevent leakage.

Pour 1 pint of SAE 140 EP gear oil into housing through

hole in top of housing. Insert relief fitting #38 into reducer

#39. Reducer should then be placed into hole on top of

gear housing. Tighten fitting and reducer secur