Maintenance, Overload protection, Opera t orʼs manual – Lincoln Electric IMt10100 WIRE FEEDER WELDER 140_180 User Manual

Page 25

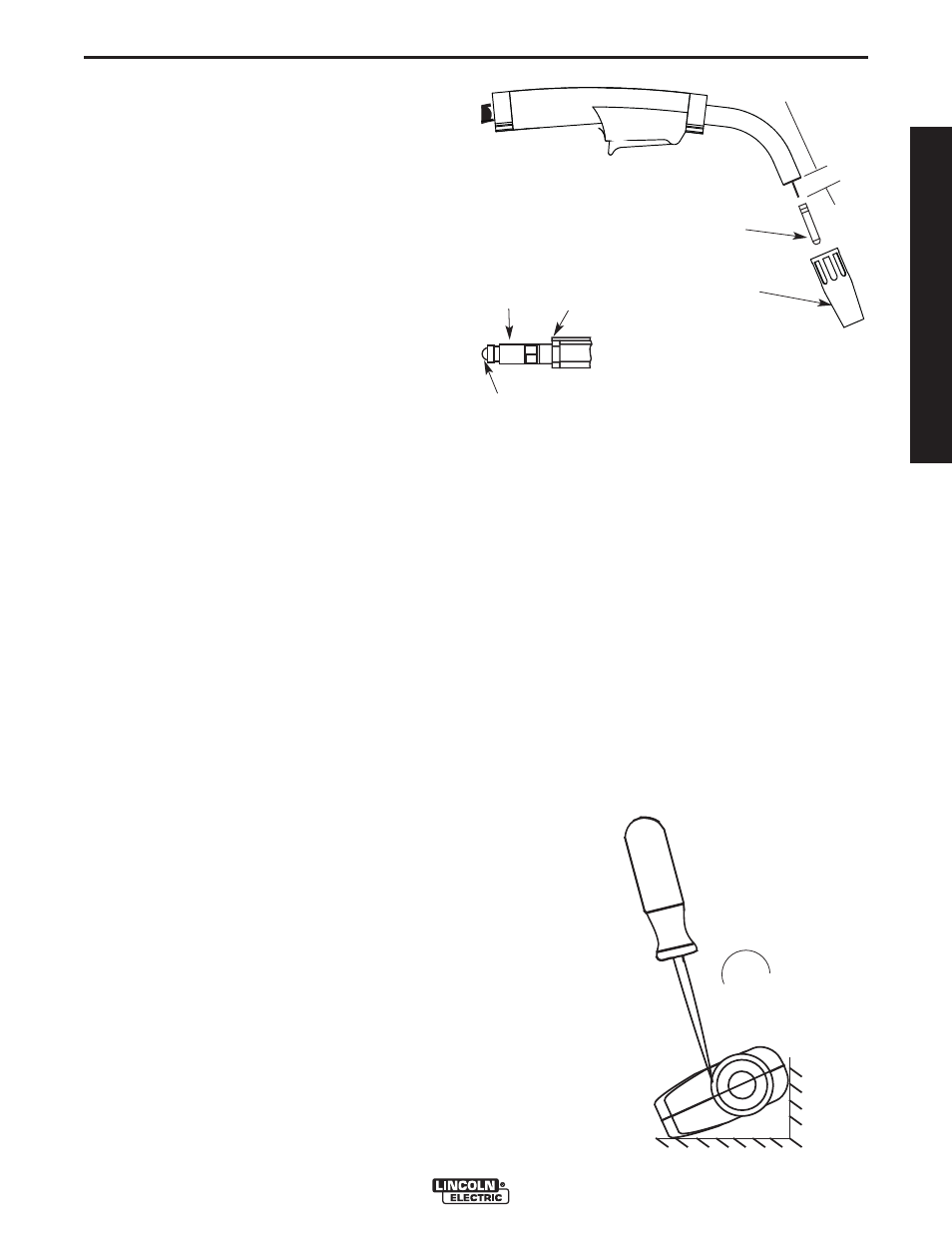

1-1/4”(31.8 mm)

Liner Trim Length

Gas Diffuser

Gas Nozzle or

Gasless Nozzle

D-2

MAINTENANCE

D-2

WIRE FEEDER WELDERS (140, 180 MODELS)

OVERLOAD PROTECTION

Output Overload

The WIRE FEEDER WELDERS (140, 180 MODELS)

is equipped with a circuit breaker and a thermostat

which protects the machine from damage if maximum

output is exceeded. The circuit breaker button will

extend out when tripped. The circuit breaker must be

manually reset.

Thermal Protection

The WIRE FEEDER WELDERS (140, 180 MODELS)

has a rated output duty cycle as defined in the

Technical Specification page. If the duty cycle is

exceeded, a thermal protector will shut off the output

until the machine cools to a reasonable operating tem-

perature. This is an automatic function of the WIRE

FEEDER WELDERS (140, 180 MODELS) and does

not require user intervention. The fan continues to run

during cooling.

Electronic Wire Drive Motor Protection

The WIRE FEEDER WELDERS (140, 180 MODELS)

has built-in protection for wire drive motor overload.

Set Screw

Brass Cable

Connector

Liner Assembly

(Liner bushing to be sealed tight

against brass cable connector)

FIGURE D.2

Liner trim length

CHANGING LINER

NOTICE: The variation in cable lengths prevents the

interchangeability of liners. Once a liner has been cut

for a particular gun, it should not be installed in anoth-

er gun unless it can meet the liner cutoff length

requirement. Refer to Figure D.2.

1. Remove the gas nozzle from the gun by unscrew-

ing counter-clockwise.

2. Remove the existing contact tip from the gun by

unscrewing counter-clockwise.

3. Remove the gas diffuser from the gun tube by

unscrewing counter-clockwise.

4. Lay the gun and cable out straight on a flat surface.

Loosen the set screw located in the brass connec-

tor at the wire feeder end of the cable. Pull the liner

out of the cable.

5. Insert a new untrimmed liner into the connector end

of the cable. Be sure the liner bushing is stenciled

appropriately for the wire size being used.

6. Fully seat the liner bushing into the connector.

Tighten the set screw on the brass cable connector.

At this time, the gas diffuser should not be installed

onto the end of the gun tube.

7. With the gas nozzle and diffuser removed from the

gun tube, be sure the cable is straight, and then

trim the liner to the length shown in the Figure D.2.

Remove any burrs from the end of the liner.

8. Screw the gas diffuser onto the end of the gun tube

and securely tighten.

9. Replace the contact tip and nozzle.

GUN HANDLE PARTS

The gun handle consists of two halves that are held

together with a collar on each end. To open up the

handle, turn the collars approximately 60 degrees

counter-clockwise until the collar reaches a stop. Then

pull the collar off the gun handle. If the collars are diffi-

cult to turn, position the gun handle against a corner,

place a screwdriver against the tab on the collar and

give the screwdriver a sharp blow to turn the collar

past an internal locking rib. See Figure D-3.

¢

Counter-clockwise

FIGURE D.3

OPERA

T

ORʼS MANUAL