Imperial, Metric, Marking* – for all material thicknesses – Lincoln Electric 718115 Spirit II 275 User Manual

Page 98

Section 5: Torch Consumables and Cutting Charts

Spirit II User’s Manual

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

5-28

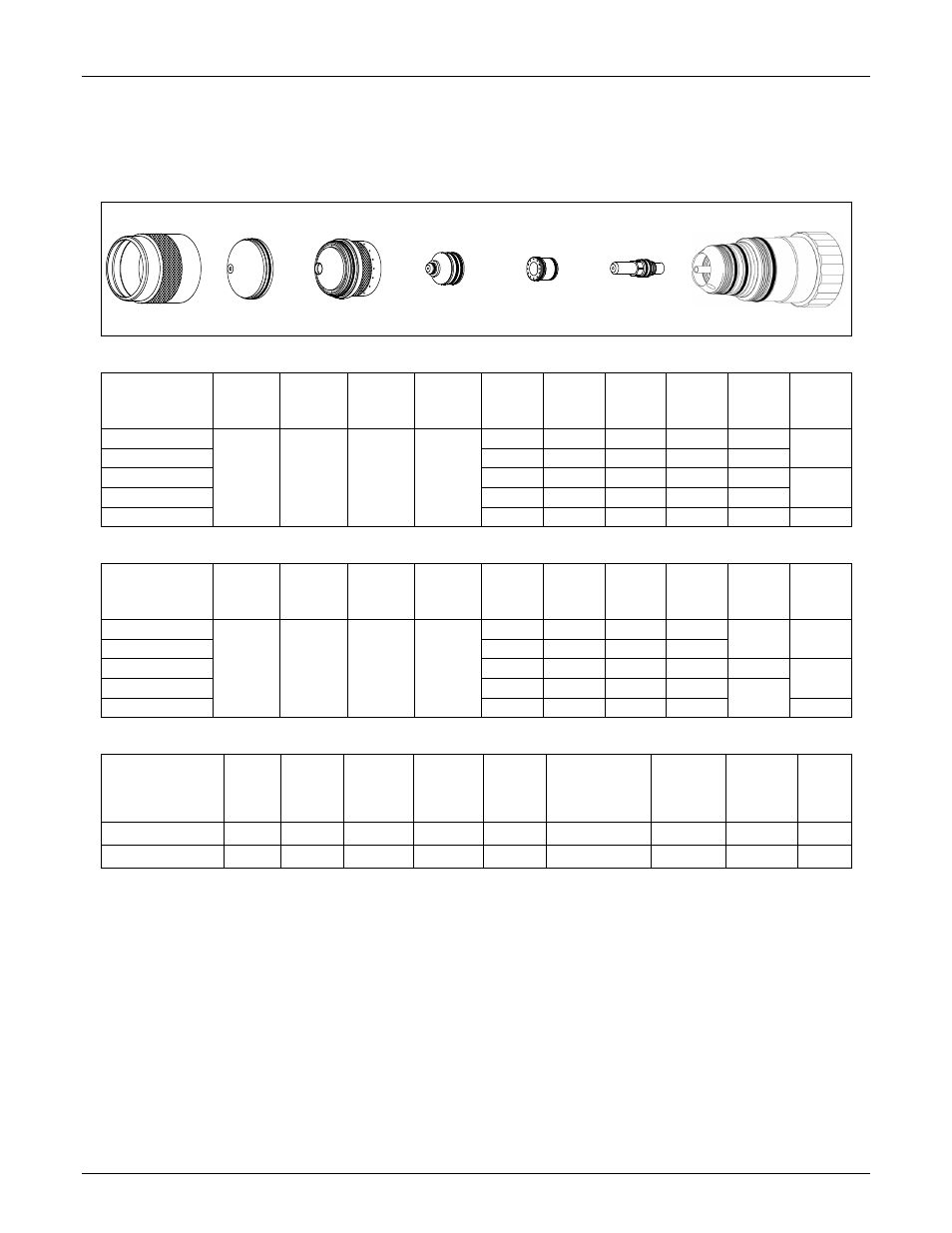

Stainless Steel - 200 Amps - H17 Plasma / Nitrogen Shield

Copper Electrode

(H17 = 17.5% Hydrogen / 32.5% Argon / 50% Nitrogen)

This gas combination gives the good cut quality and minimum dross levels

Shield Cap

Nozzle

Electrode

277274

277287

277135

Outer Cap

Retaining Cap

Swirl Ring

Torch Head

284150

277266

277259

279100

Imperial*

Material

Thickness

Preflow

Plasma

Shield

Postflow

Arc

Voltage

Travel

Speed

Cutting

Height

Pierce

Height

Pierce

Time

Kerf

Width

(in)

(psi)

(psi)

(psi)

(psi)

(volts)

(ipm)

(in)

(in)

(msec)

(in)

3/8

37

72

79

68

156

80

.195

.250

500

.150

1/2

148

75

.130

.300

600

5/8

155

60

.190

.350

800

.155

3/4

160

50

.200

.400

1200

1.0

170

35

.240

.450

1500

.160

Metric*

Material

Thickness

Preflow

Plasma

Shield

Postflow

Arc

Voltage

Travel

Speed

Cutting

Height

Pierce

Height

Pierce

Time

Kerf

Width

(mm)

(psi)

(psi)

(psi)

(psi)

(volts)

(mm/m)

(mm)

(mm)

(msec)

(mm)

10

37

72

79

68

154

2010

4.7

6.5

600

3.8

12

149

1935

3.6

7.3

16

155

1515

4.8

8.9

800

3.9

20

161

1215

5.2

10.3

1500

25

169

915

6.0

11.3

4.1

Marking* – For All Material Thicknesses

Type of Gas

Preflow Plasma

Shield

Postflow

Arc

Voltage

Travel

Speed

Marking

Height

Initial

Height

Pierce

Time

(Plasma) (Shield)

(psi)

(psi)

(psi)

(psi)

(volts)

(ipm) (mm/min) (in) (mm) (in) (mm) (msec)

Nitrogen Nitrogen

N/A

25

25

N/A

120

250

6350

.100 2.5 .100 2.5

0

Argon** Nitrogen**

N/A

50

25

N/A

72

100

2540

.120 3.0 .100 2.5

0

* Use an arc transfer height (ignition height) of .200” (5.1 mm) for cutting and .100” (2.5 mm) for marking.

** Only available on systems with the Automatic Gas Console.

(Revised 04/26/2013)