Operation, Welding controls – Lincoln Electric IM10047 RED-D-ARC GX300 User Manual

Page 18

B-2

OPERATION

B-2

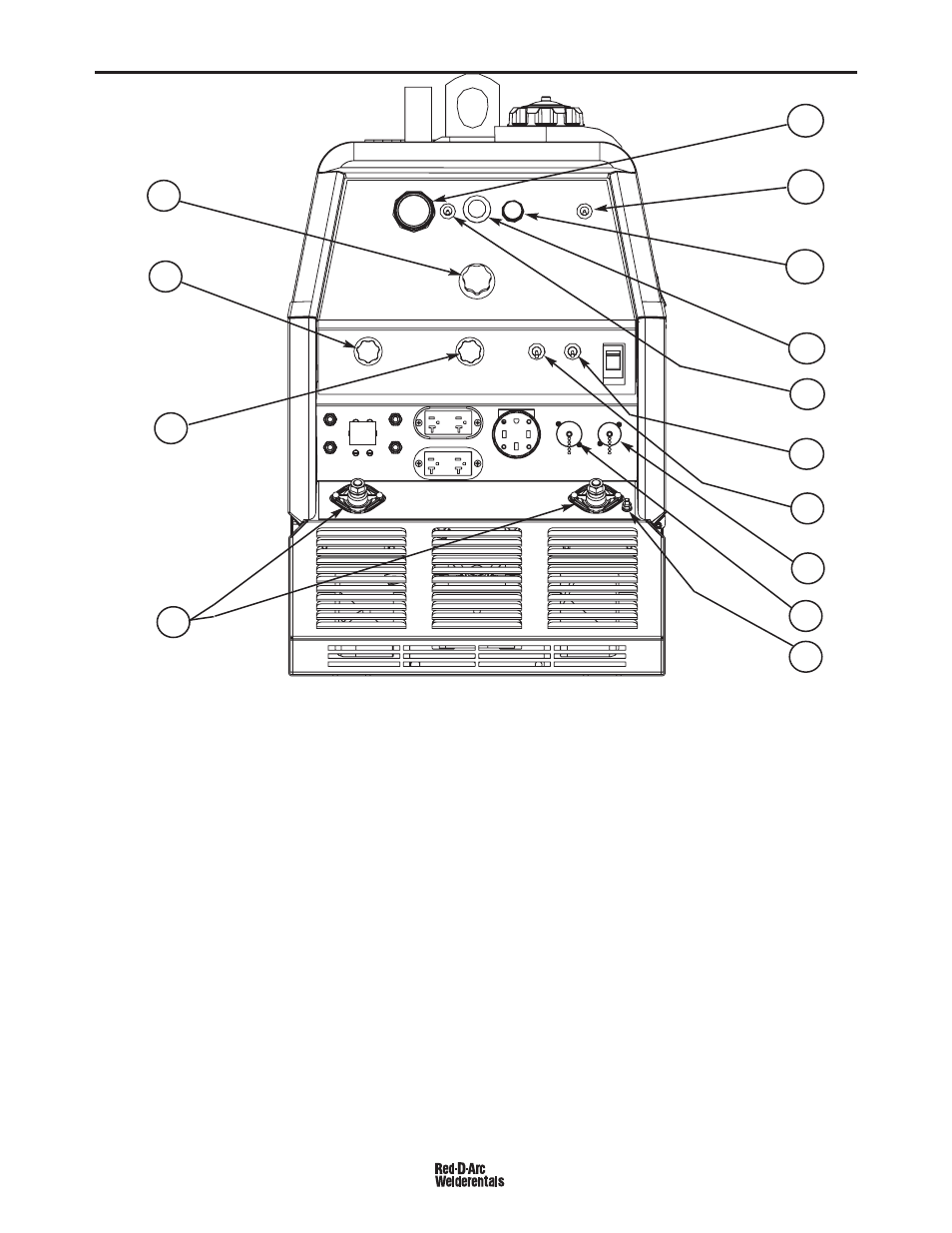

WELDING CONTROLS

1. OUTPUT CONTROL:

The CONTROL dial provides continuous control of the

welding current or welding voltage depending on the

selected welding mode. This control is not active in the

CC-STICK, PIPE, and CV-WIRE modes when a remote

control or wire feeder with remote control is connected

to either the 3-pin or 14-pin Amphenol.

2. WELD MODE SELECTOR SWITCH:

(Provides four selectable welding modes)

CV-WIRE

PIPE

CC-STICK

TOUCH START TIG

3. ARC CONTROL

:

The ARC CONTROL WIRE/STICK dial is active in the

WIRE, STICK and PIPE modes, and has different func-

tions in these modes. This control is not active in the TIG

mode.

CC-STICK, PIPE modes In these modes, the ARC CON-

TROL knob sets the short circuit current during stick

welding (arc-force). Increasing the number from -10 to

+10 increases the short circuit current and prevents stick-

ing of the electrode to the plate while welding. This can

also increase spatter. It is recommended that the ARC

CONTROL be set to the minimum number without elec-

trode sticking. Start with a setting at 0.

CV-WIRE mode: In this mode, turning the ARC CON-

TROL clock wise from –10 (soft) to +10 (crisp) changes

the arc from soft and washed-in to crisp and narrow. It

acts as an inductance control. The proper setting

depends on the procedure and operator preference. Start

with a setting of 0.

GX 300

1

9

6

3

8

4

7

10

11

12

5

14

13

2