Operation, Case back controls – Lincoln Electric IM10083 POWER WAVE R350 User Manual

Page 22

B-4

OPERATION

B-4

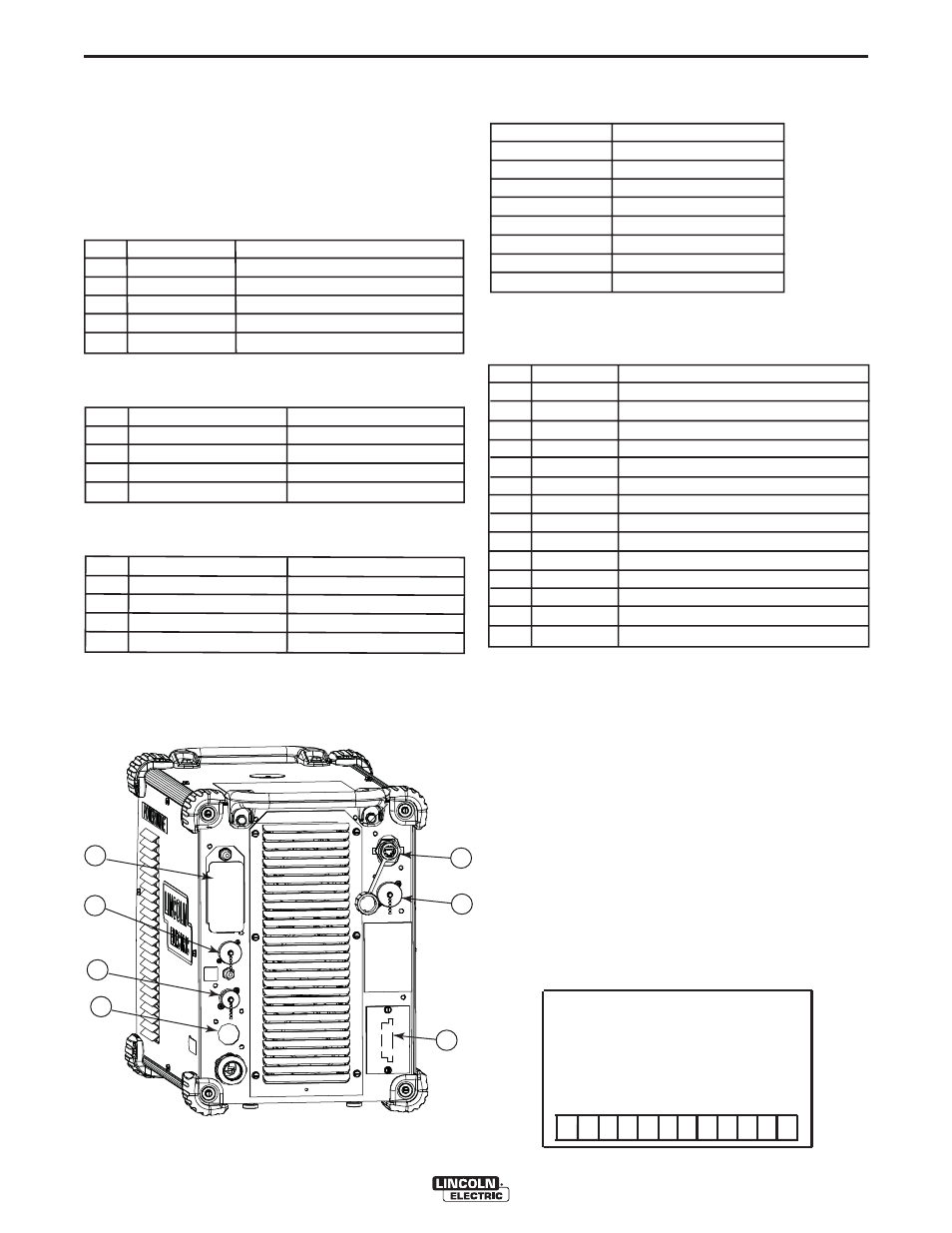

CASE BACK CONTROLS

(See Figure B.2)

1. 115V / 15A DUPLEX RECEPTACLE AND

CIRCUIT BREAKER 1 (10 AMP): Provides protec-

tion for the 115V auxiliary.

2. ARCLINK

®

RECEPTACLE AND CIRCUIT

BREAKER 2 (10 AMP):

Pin

Lead

Function

A

53A / 53B

Communication Bus L

B

54A / 54B

Communication Bus H

C

67A / 67B

Electrode Voltage Sense

D

52A / 52B

+40V DC

E

51A / 51B

0 VDC

3. SYNC-TANDEM CONNECTOR (4 PIN – MS

STYLE):

Pin

Lead Function

A

WHITE

“Ready” H

B

BLACK/RED

“Ready” L

C

GREEN

“Kill” H

D

BLACK/GREEN

“Kill” L

4. OPTIONAL DEVICENET CONNECTOR (5 PIN –

SEALED MINI STYLE):

Pin

Lead Function

2

894

+24 VDC DeviceNet

3

893

Common DeviceNet

4

892

DeviceNet H

5

891

DeviceNet L

5. ETHERNET CONNECTOR (RJ-45): Used for

ArcLink

®

XT communication. Also used for diag-

nostics and reprogramming the Power Wave R350.

Pin

Function

1

Transmit +

2

Transmit -

3

Receive +

4

---

5

---

6

Receive -

7

---

8

---

6. WIRE FEEDER RECEPTACLE (14-PIN): For con-

nection to the Auto Drive 4R100/4R220 and

PF10R series wire feeders.

Pin

Lead

Function

A

539

Motor +

B

541

Motor -

C

521

Solenoid +

D

522

Solenoid Common

E

845

Tach 2A differential signal

F

847

Single Tach input

G

841

+15V Tach supply

H

844

Tach common

I

Open

Reserved for future use

J

Open

Reserved for future use

K

842

Tach 1A differential signal

L

843

Tach 1B differential signal

M

846

Tach 2B differential signal

N

67G

Electrode Voltage Sense

7. OPTIONAL EXTERNAL I/O CONNECTOR:

Terminal Strip for making simple input signal connec-

tions. (See Figure B.2a)

The terminal strip is divided into three groups:

Group #1 - TRIGGER

Group #2 - FEED FORWARD/REVERSE

Group #3 - SHUTDOWN INPUTS

When the Power Wave S350(CE) is controlled via

DeviceNet, the “TRIGGER” and “Feed” groups can

interfere with the welding sequence and should not be

used.

All inputs use "normally open" logic except the shut-

down group. The shutdown inputs use "normally

closed" logic, and are always enabled. Unused shut-

downs must be tied to the +15V supply for the shut-

down group. Machines are shipped from the factory

with jumpers installed on both shutdown inputs.

POWER WAVE

®

R350

1

2

3

4

5

6

7

FIGURE B.2

FIGURE B.2a

1

2

3

4

5

6

7

8

9

10

11

12

+15VDC - Group #1

T

rigger

Dual Procedure

+15VDC - Group #2

Feed Forward

2/4 Step

Gas Purge

Feed Reverse

+15VDC - Group #3

Shutdown 1 Input

Shutdown 2 Input