Lincoln Electric IM10180 POWER FEED 25M NNS User Manual

Page 25

B-10

OPERATION

POWER FEED™ 25M NNS

Process

SMAW

(Stick)

GMAW

(MIG) and

FCAW

(Flux-cored)

GMAW-P (Pulsed

MIG), Steel and

Stainless

Wave Control

Name

Arc Force

Pinch

Ultimarc

Effect / Range

Soft (-10.0) to

Crisp (10.0)

Soft (-10.0) to

Crisp (10.0)

Soft (-10.0) to

Stiff (10.0)

Description

Arc Force adjusts the short circuit current for a soft arc, or for a forceful, driving

arc. It helps to prevent sticking and shorting of organic coated electrodes, partic-

ularity globular transfer types such as stainless and low hydrogen. Arc Force is

especially effective for root pass on pipe with stainless electrode and helps to

minimize spatter for certain electrodes and procedure as with low hydrogen, etc.

Pinch controls the arc characteristics when short-arc welding.

Ultimarc regulates the focus or shape of the arc. Ultimarc values greater than

0.0 increase the pulse frequency while decreasing the background current,

resulting in a tight, stiff arc best for high speed sheet metal welding. Ultimarc

values less than 0.0 decrease the pulse frequency while increasing the back-

ground current, for a soft arc good for out-of-position welding.

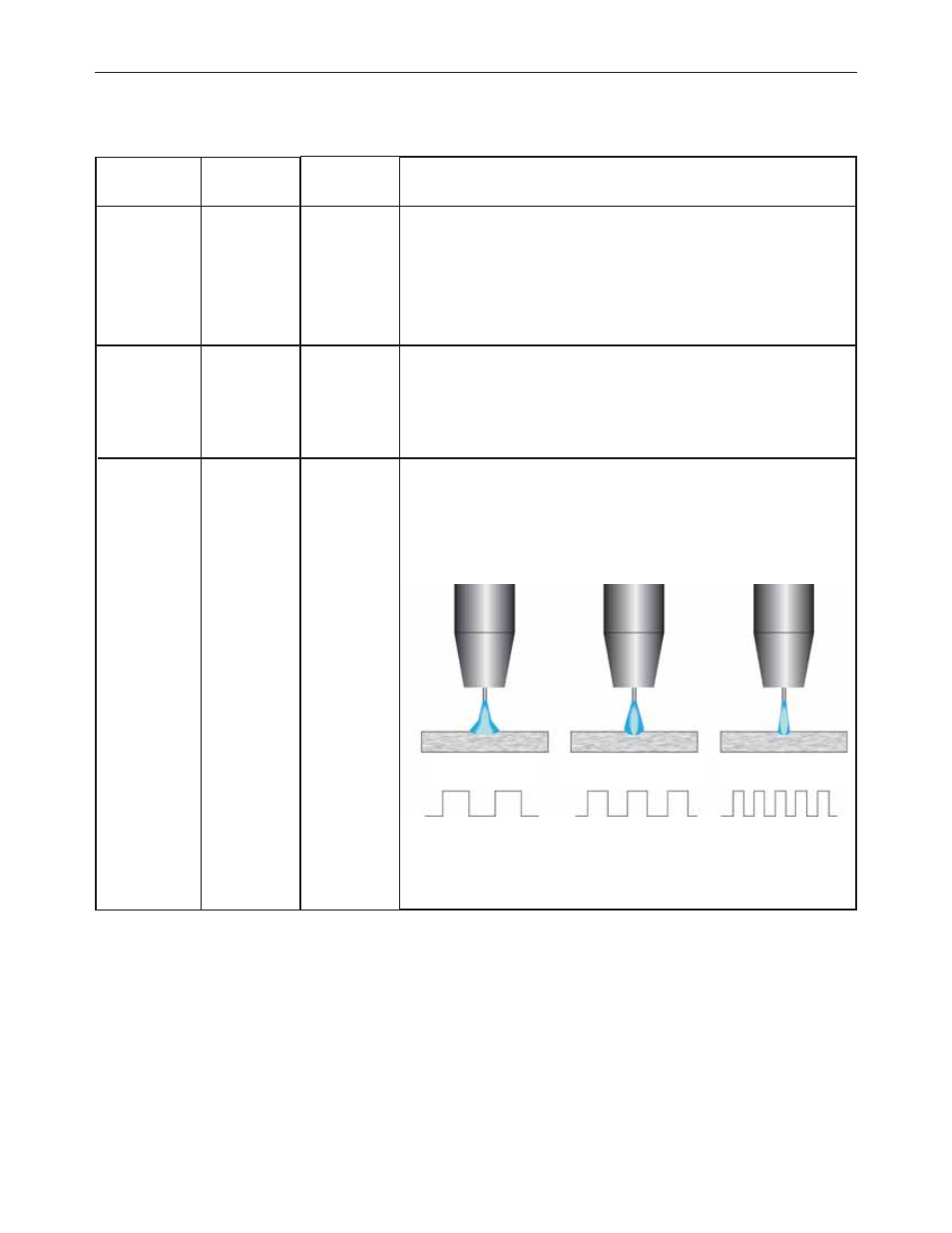

For Pulse modes, Arc Control changes the pulsing frequency. When the frequen-

cy changes, the Power Wave system automatically adjusts the background cur-

rent to maintain a similar heat input into the weld. Low frequencies give more

control over the puddle and high frequencies minimize spatter.

WAVE CONTROL

Wave Control is used to adjust the arc for exact preferences. The wave control functions vary for different processes and weld modes.

Arc Control -10.0

Low Frequency, Wide

Arc Control OFF

Medium Frequency and Width

Arc Control +10.0

High Frequency, Focused