Operation – Lincoln Electric IM10134 COOL ARC 55 S WATER COOLER User Manual

Page 13

B-2

OPERATION

B-2

The coolant FLOW INDICATOR is accessed by removal of

the fill cap. Actual return flow is directly visible, via the fill

opening.

When first starting the unit, check all of the coolant hoses to

ensure that no water leaks are present. Water leakage

causes poor welding performance, poor cooling perfor-

mance, low welding component life and potential electrical

safety hazards.

• The cooler will automatically turn “ON” when the trigger is

pulled.

• The cooler will automatically turn "OFF" when welding is

not taking place for long periods of time.

• The manual control switch on the front of the cooler can

be used to run the cooler without the “smart” features.

This should be used to prime the system on initial setup

and when changing guns.

• Never operate the cooler with the reservoir fill cap

removed. Unless checking coolant flow.

• Avoid kinking or putting sharp bends in any water lines.

• Keep all water lines clean and free of any blockage.

• Do not operate cooler without coolant in reservoir. Never

run pump dry.

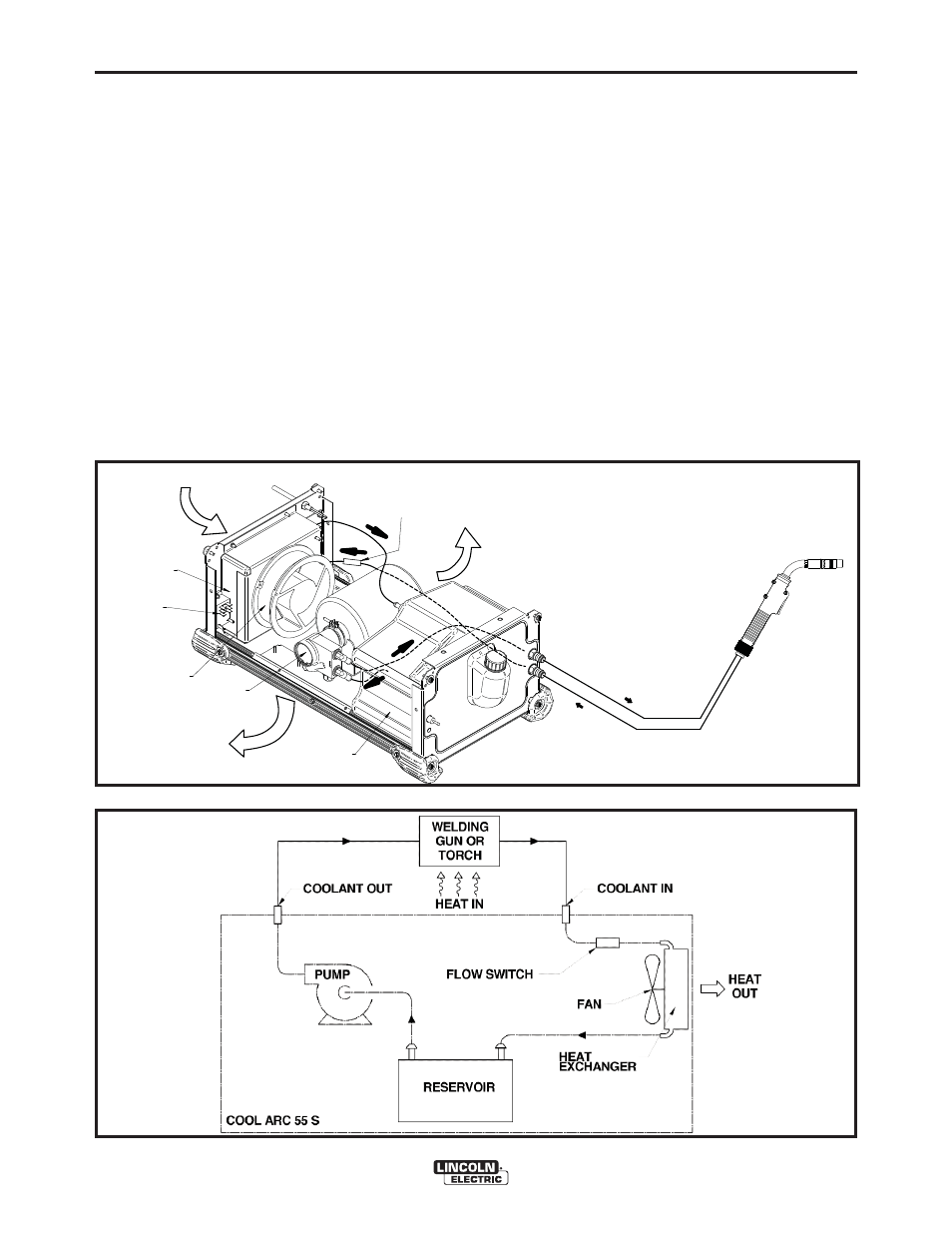

COOLING EFFICIENCY

The high cooling efficiency of the COOL ARC

®

55 S offers a

cooler, more comfortable weld than conventional air-cooled

procedures as well as leading competitors water cooled sys-

tems.

The COOL ARC

®

55 S effectively removes the heat of the

arc away from the gun or torch handle and places it into the

exiting air flow at the sides of the cooler. Ambient air tem-

perature affects the coolant temperature of the COOL ARC

®

55 S.

COOL ARC

®

55 S

CO

OL

ANT

CO

OL

ANT

ROOM AIR IN

HOT

AIR

OUT

HOT

AIR

OUT

PUMP

HEAT

EXCHANGER

FAN

RESERVOIR

FLOW

SWITCH

RELAY

FIGURE B.1

Coolant Circulation Diagram

FIGURE B.2