Troubleshooting, 7troubleshooting – Lincoln Electric IM10070 Control Box CB-WCS User Manual

Page 14

CONTROL BOX CB-WCS

6

Observe all safety guidelines detailed throughout this

instruction manual.

This troubleshooting guide is provided to help you locate

and repair possible machine malfunctions. Simply follow the

four-step procedure listed below.

Step 1: Symptom

The first column labeled “Symptom” describes possible

symptoms that the machine may exhibit. Find the listing that

best describes the symptoms that the machine is exhibiting.

Step 2: Locate Problem

The second column “Problem” describes the possible

consequences of the found symptom.

Step 3: Possible Cause

The third column labeled “Possible cause” lists the obvious

external possibilities that may contribute to the machine

symptom.

Step 4: Solution

The fourth column labeled “Solution” provides a course of

action for the possible cause. Generally it states to contact

your local Lincoln Authorized Field Service Facility.

7

TROUBLESHOOTING

A number problems in the checklist below can also

be caused by defects in the connected equipment.

This manual mainly deals with problems and

solutions directly related to the product itself.

WARNING!

Service and repair should only be performed by

Lincoln Electric Factory Trained Personnel.

Unauthorized repairs performed on this equipment

may result in danger to the technician and machine

operator and will invalidate your factory warranty.

For your safety and to avoid electrical shock,

please observe all safety notes and precautions

detailed throughout this instruction manual.

CAUTION!

If for any reason you do not understand the test

procedures or are unable to safely perform the

tests and repairs, contact your Local Lincoln

Authorized Field Service Facility for technical

troubleshooting assitance before you proceed.

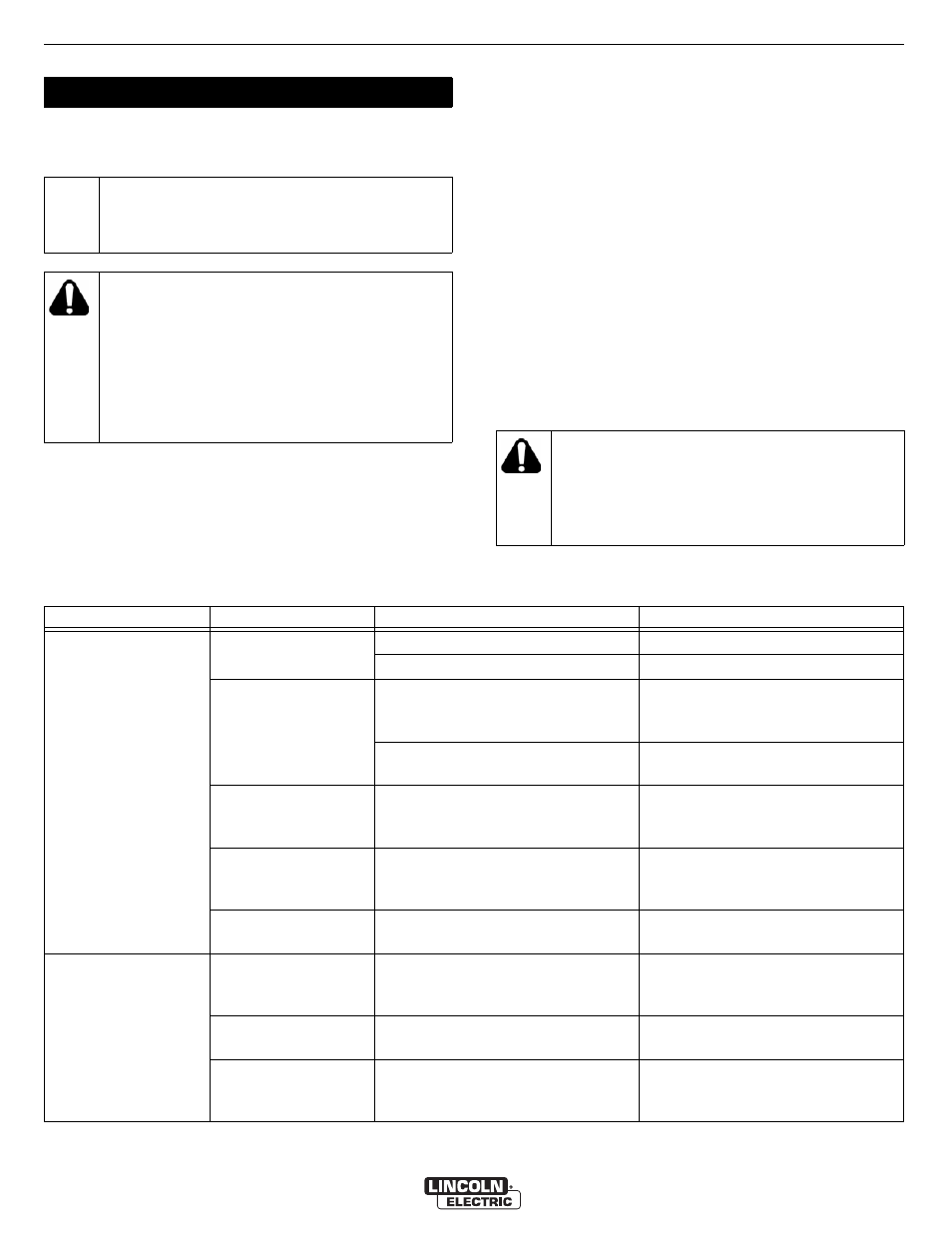

Table 1: Troubleshooting guide

Symptom

Problem

Possible Cause

Solution

No extraction when

welding starts.

Fan motor does not

start.

Thermal breaker activated.

Reset thermal breaker.

No power connected to the CB-WCS. Check power supply.

Sensor of WCS not

activated.

Sensor defective.

Check sensor function with a small

magnet. Red LED should lit on the

sensor.

Sensor not connected to the ground

cable of the welding machine.

Connect sensor to the ground cable

of the welding machine.

Sensor

malfunctioning.

Sensor broken.

Check sensor input on circuit board.

Input LED should be lit when the

sensor LED is activated

Power supply failing.

Fuse in CB-WCS broken.

Check fuse and try to determine why

the fuse blew (e.g. short circuit) and

repair.

Delay timer.

Start delay timer activated.

Please see if you want the start delay

timer to be active.

Fan keeps running

without welding

activities.

Sensor.

Sensor defective.

Check sensor function with a small

magnet. Red LED should lit on the

sensor.

Delay timer.

Stop delay timer activated (0-5

minutes).

Please see if you want the stop delay

timer to be active.

Arc sensor in use.

AST has its own delay time with a

minimum of 12 seconds stop delay

and a maximum of 2 minutes.

See if you need to change the delay

time in the AST sensor.