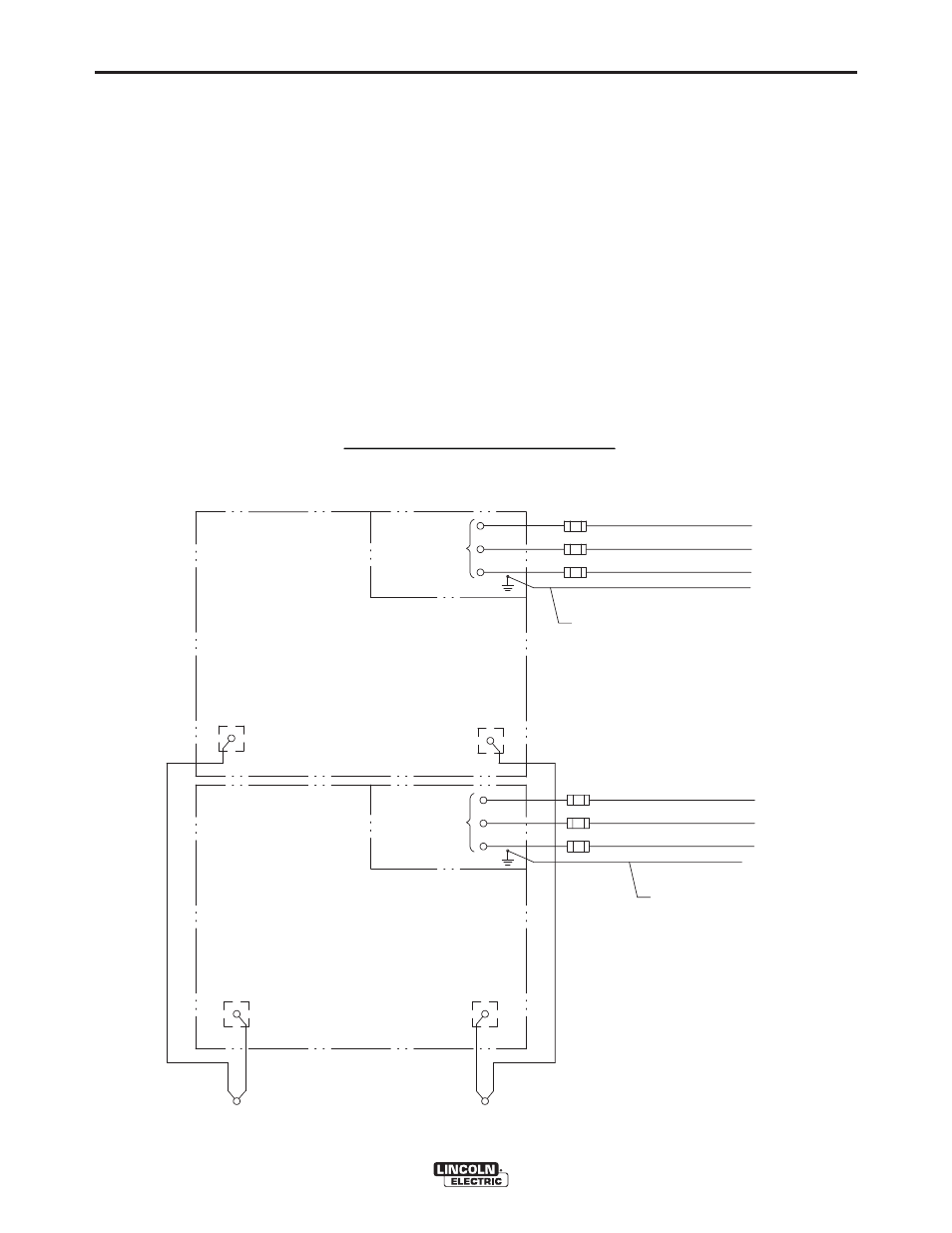

Installation, Paralleling diagram, A-7 control cable connections – Lincoln Electric IM10132 FLEXTEC 650 User Manual

Page 13: Paralleling

A-7

INSTALLATION

FLEXTEC™ 650

A-7

CONTROL CABLE CONNECTIONS

General Guidelines

Genuine Lincoln control cables should be used at all

times (except where noted otherwise). Lincoln cables

are specifically designed for the communication and

power needs of the FLEXTEC™ 650. Most are

designed to be connected end to end for ease of

extension. Generally, it is recommended that the total

length not exceed 100 feet (30.5 m). The use of non-

standard cables, especially in lengths greater than 25

feet, can lead to communication problems (system

shutdowns), poor motor acceleration (poor arc start-

ing), and low wire driving force (wire feeding prob-

lems). Always use the shortest length of control cable

possible, and DO NOT coil excess cable.

Regarding cable placement, best results will be

obtained when control cables are routed separate

from the weld cables. This minimizes the possibility of

interference between the high currents flowing

through the weld cables, and the low level signals in

the control cables.

PARALLELING

FLEXTEC™ 650 power sources may be paralleled for

increased output requirements. No kit is required for

paralleling of FLEXTEC™ 650 power sources. The

FLEXTEC™ 650 can only be paralleled for constant

current processes (mode switch must be in the SMAW

position). Connect the power sources as shown, and

set the output control of each power source to one

half of the desired arc current. (See Figure A.3)

POSITIVE

AT W

WORK P

PIECE

POSITIVE

AT W

WORK P

PIECE

POSITIVE

A A

NEGATIVE

VE

W

W

PARALLELING DIAGRAM

V

U

U

IIN

NP

PU

UT

T

T

TE

ER

RM

MIIN

NAL

AL

V

V

W

W

IIN

NP

PU

UT

T L

LIIN

NES

ES

A A

N

NE

EG

GA

AT

TIIVE

VE

TO G

GROUN

UND

ELECTRICAL C

CODE

PE

PER N

NATIONAL

U

GND

N

NE

EG

GA

AT

TIIVE

VE

T

TO G

GROUN

UND

G

GND

PER N

NATIO

ONAL

ELECTRICAL C

CODE

BLOCK

F

FL

LE

EX

XT

TE

EC

C 6

65

50

0

((M

MA

AC

CH

HIIN

NE

E #1

#1))

F

FL

LE

EX

XT

TE

EC

C 6

65

50

0

((M

MA

AC

CH

HIIN

NE

E #2

#2))

IIN

NP

PU

UT

T

T

TE

ER

RM

MIIN

NAL

AL

B

BL

LO

OC

CK

K

W

W

V

U

U

V

V

W

W

IIN

NP

PU

UT

T L

LIIN

NES

ES

U

U

FIGURE A.3