Vestil OLA series User Manual

Page 2

2

OPERATION

This lifter is designed to be used in conjunction with

closed bottom skids. Loads used wit this lifter needs to

be secure on the skid and symmetrically distributed on

the skid. Loose items falling off the pallet midair can

cause the center of gravity to shift and cause the entire

load to dump.

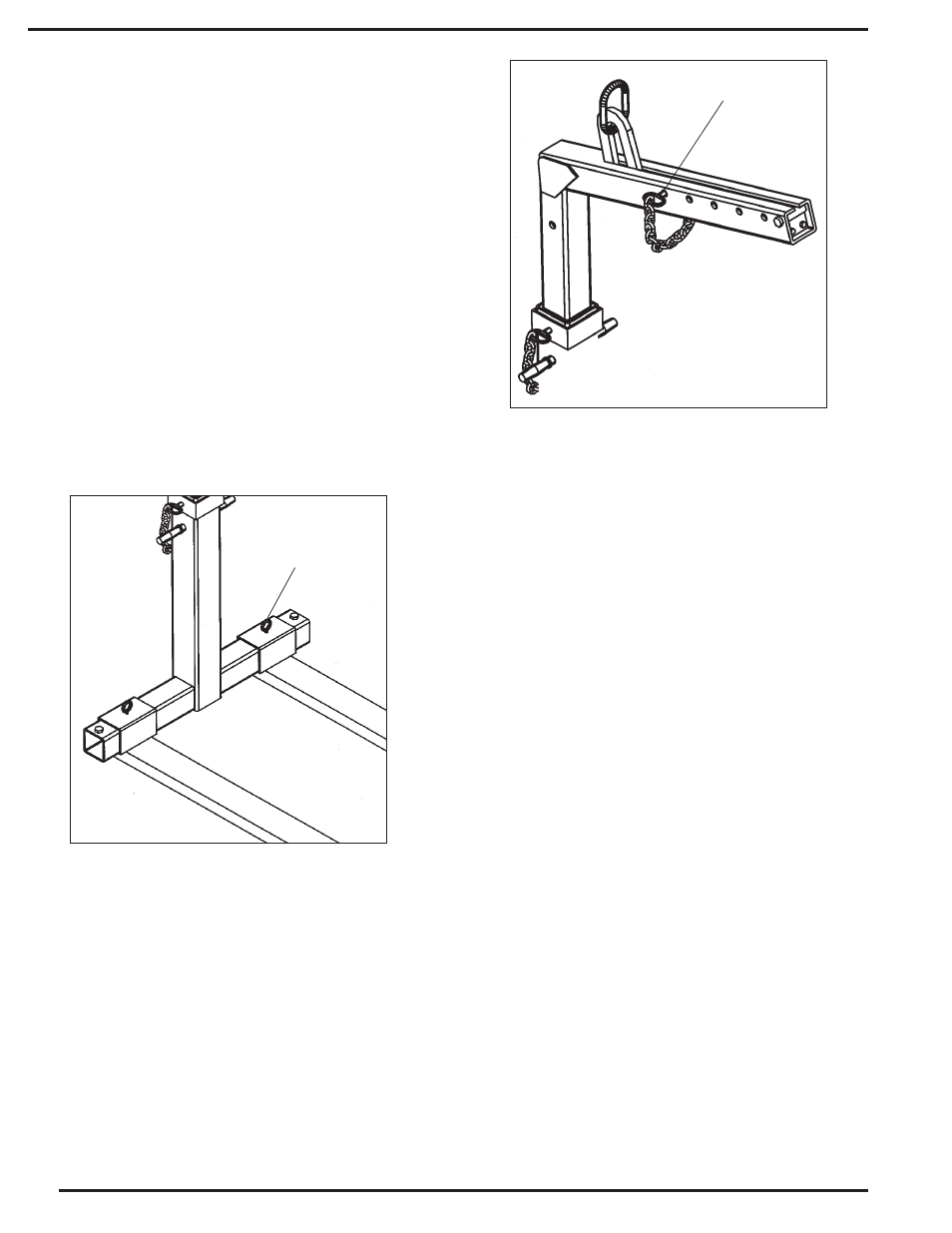

Place the forks of the pallet lifter through the pallet fork

slots until the forks are fully inserted. If the inside

clearance height needs to be adjusted, remove the rear

pin and either set the height with a hoist hooked into the

bail or by hand. After setting the height, replace the pin

and install the safety pin. Models with the adjustable

fork width option can set the fork width by loosening the

retainer bolts on the top of each fork and sliding the

forks to the desired width. The forks must be set the

same distance from the center in order to insure proper

balance. After the forks have been set retighten the

retaining bolts securely.

Fork Retaining Bolt

Using the overhead hoist, pick up the pallet lifter and

load slowly to check for load balancing and stability. If

the load is not balanced position the pallet on the forks

and retry. Never extend the pallet past the edge of the

forks. Never extend the pallet past the edge of the forks.

If the pallet center balance is off enough, the bail stop

pin may need to be repositioned.

When trying to position the pallet lifter with the load, use

the handles located on the rear of the unit. Never place

your feet underneath the unit when positioning the

load. To remove the pallet from the lifter, place the load

on the ground and with the lifter slightly raised remove

the pallet lifter from the rear of the pallet. When the

weight of the pallet has been removed from the forks,

the pallet lifter bail will slide back and allow the lifter to

balance when unloaded.

INSPECTIONS

As with all equipment, frequent inspections should be

preformed on this unit to insure safe operation. The

intervals of inspection should be determined by the

frequency of use. Inspect for cracked welds, worn or

damaged components or torn or damaged warning

labels. This lifter is built in accordance with ASME

B30.20. A copy of this standard can be attained from

ASME. Guidelines for testing and inspections are given

in this standard.

Bail Restraint Pin

Set the bail restraint pin so that the bail will stop at

approximately the center of the load. Be sure all pins

are in place and the safety pins are inserted into the

pins. Connect the hoist hook through the bail pickup

loop on the pallet lifter. Be sure that the hoist has a

safety latch to insure the hook cannot slide off the bail.

When moving the pallet lifter empty, the bail will return

to the lower position. To be sure the bail does not slide

forward, place the bail adjustment pin into the first hole

position (first hole on the lower end).