Vestil PDL-800-M User Manual

Vestil Equipment

09/11/03.

09/22/03

PDL-800-M user instructions.doc

1 of 1

O

PERATION

I

NSTRUCTIONS

-- PDL-800-M

Æ

Consult standard ASME/ANSI B30.20, “ Below-The-Hook Lifting Devices,” for information regarding use and care

guidelines of this drum lifting device.

Æ

Ensure that all employees involved in the operation of this device understand and follow all of the following!

Intended use:

The PDL-800-M, Multi-Purpose Overhead Drum Lifter/Wrench, is intended to be used with 55- or 30-gallon steel, plastic,

or fiber drum having a closed head and top lip. It can transport one (1) barrel, with a maximum capacity of 800 pounds.

During use it is suspended by a hoist, fork truck attachment, or other overhead lifting means having an appropriate lifting hook.

!

Caution:

Check with the barrel manufacturer to ensure that a barrel’s rim design is adequate to be used with this style of

drum lifter.

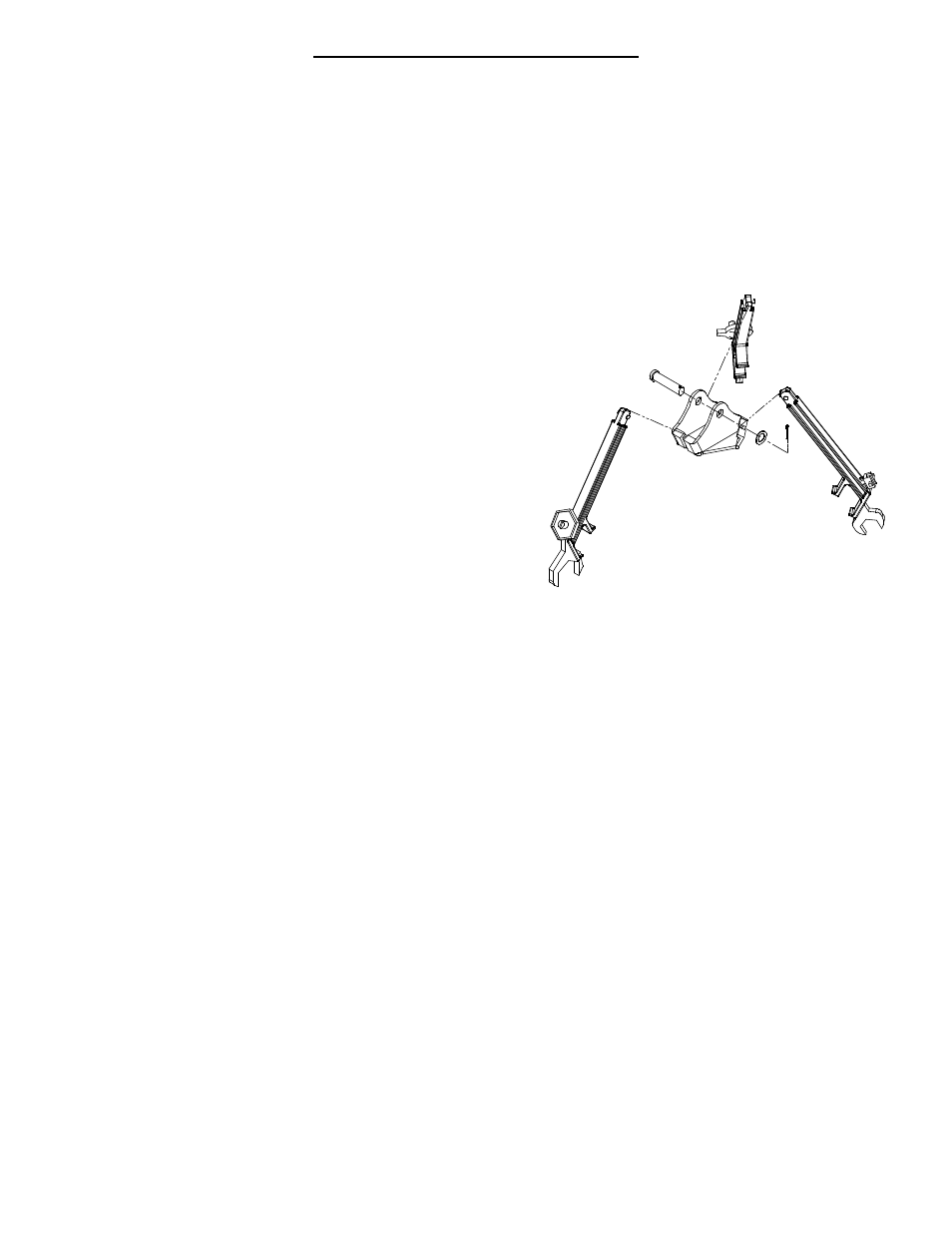

Ar m assembly:

ü Attach the blue hook casting to the hook of the hoist or

fork truck attachment that will be used to raise the barrel.

ü To assemble the drum lifter, place the narrow end of each

arm into a slot in the hook casting. When the end of the arm is

completely down into the slot, pull the arm outward so that the

cross pin at the end of the arm is captured under the flanges on

either side of the slot.

ü Release the arm so that it can hang freely from the hook casting.

Ø Note: The arms of the PDL-800-M can be removed

from the hook casting to facilitate the opening or removal

of various drum plugs, faucets, and rim ring bolts.

!

Caution:

Do not use the arms to strike or hammer on any surface.

Oper ation:

Note:

Always assess the condition of the drum and its rim before attaching the drum lifter.

Inspect the drum lifter before each use.

!

Caution:

Never use the drum lifter if any damage is seen or suspected.

!

Caution:

The drum lifter and its associated equipment must only be used on a smooth, firm, level surface.

!

Caution:

Do not exceed a rate of two (2) feet per second when transporting a drum.

•

Inspect the drum’s rim to verify that it is in good condition and is capable of supporting the load contained in the drum.

!

Warning:

Lubricants or accumulated material around the rim of the drum could affect its ability to safely hold a

suspended drum. The drum’s surface texture and the top rim projection must also be considered.

•

Center the drum lifter over the drum to be moved and lower it close to the top of the drum.

•

The arms must be held outward and the drum lifter lowered to allow the rim hook on each arm to engage the side of the

barrel underneath the drum’s top rim.

Note:

For 55-gallon drums, use the lower of the two hooks. For 30-gallon drums, use the higher of the two hooks.

•

Slowly raise the drum lifter until the hook on each arm has made contact with the drum’s rim.

•

Verify that each arm’s hook is positively engaged under the drum’s rim.

•

Slowly raise and move the drum, continuously monitoring the hooks to ensure they maintain their position under the

drum’s rim.

!

Warning:

Do not place your hands, feet, or any part of your body underneath a suspended drum. Do not transport a drum

over the heads of personnel, and keep all personnel well clear of a suspended drum at all times.

Whenever it is not being used, keep the drum lifter in a location where it will be protected against damage.

Consult the manufacturer with any questions or to inquire about replacement parts. Always include the product’s model

number and serial number in any correspondence. The product’s serial number can be found on the top of the hook casting.