Superwinch EX1 – 453 kgs/12V (1110) User Manual

Page 6

6

MOUNTING (CONT.)

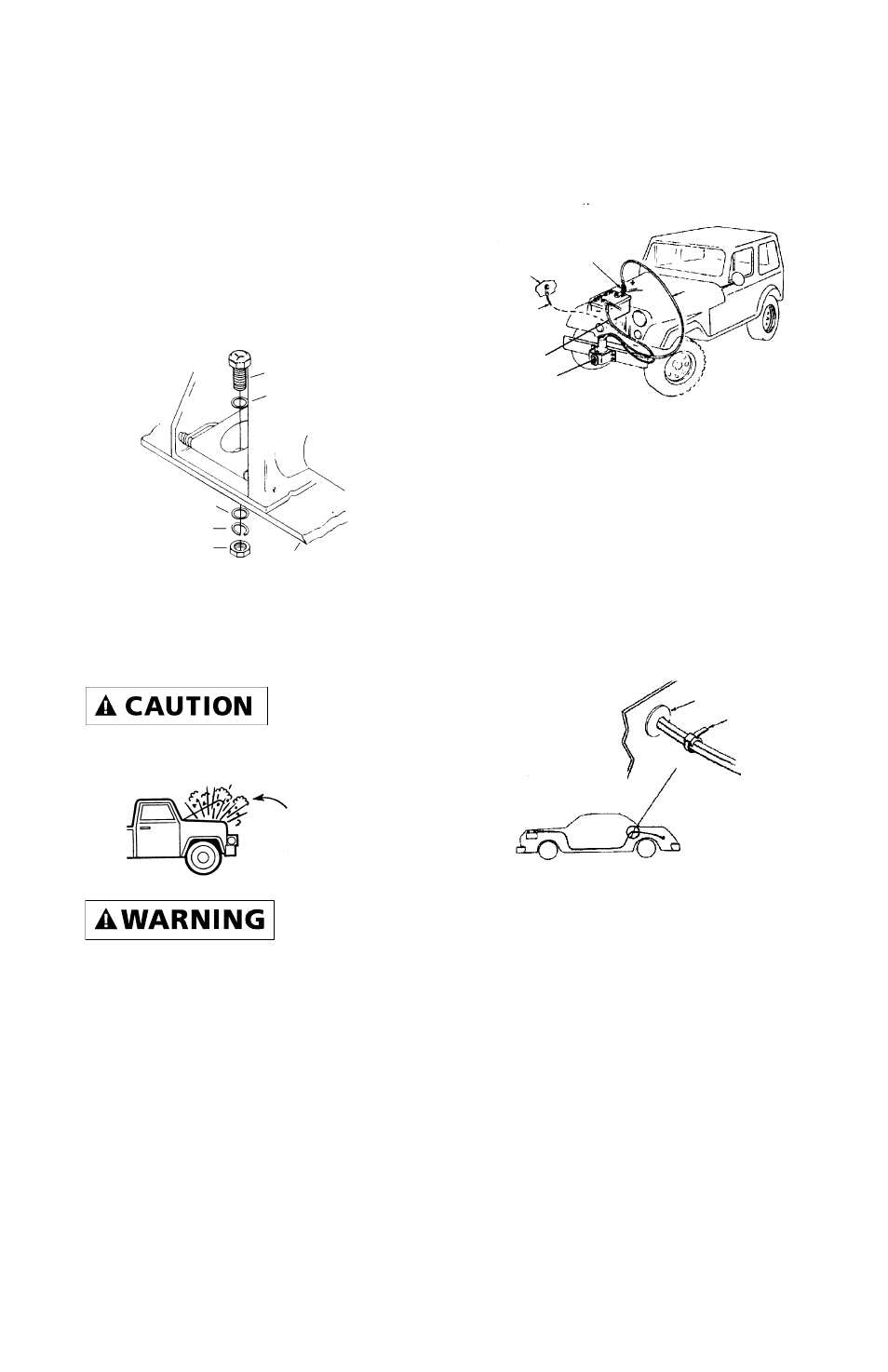

Drill two 7/16" (12mm) diameter

holes with center lines exactly

3-11/16" (93.66mm) apart (Figure 7)

in the support chosen for the

winch. Attach the winch to the sup-

port with two (2) 3/8-16 Hex Head

Bolts. Be sure the hardware is

assembled as shown. Tighten the

hardware to 35 lb. ft. torque.

ELECTRICAL INSTALLATION

This winch operates on standard

automotive 12-volt Direct Current.

Do not

connect winch

to 110 Volt house current. Motor

damage or fatal shock may occur.

Automobile

batteries con-

tain gasses which are flammable and

explosive. Wear eye protection dur-

ing installation and remove all metal

jewelry. Do not lean over the bat-

tery while making connections.

The red wire from the switch is

connected to the circuit protector

terminal using the hardware pro-

vided. The other end of the circuit

protector is connected to the bat-

tery positive terminal. The black

wire from the switch is connected

to the battery negative terminal

(Figure 8). Be sure connections are

clean and tight. Do not connect the

switch or wiring to any other power

source in the vehicle.

Starting at the winch, feed the

wires into the engine compartment.

If possible, use the routing and sup-

port for the existing wiring.

If it is necessary to drill holes, to

feed the wires, be sure the wires

are protected from damage by

using a grommet (Figure 9). Use

cable ties to secure wires along the

route.

When you make the ground con-

nection, be sure to scrape off any

dirt from the bolt that would pre-

vent a good connection.

Note: If the winch is mounted at

the rear of the vehicle, a special

wiring kit (P/N 1520) is available

from Superwinch.

When extending the lead wires for

rear vehicle mount, always use 8

gauge wire or heavier to extend the

existing wires to the battery.

Figure 7

Bolt

Flat Washer

Support

Flat Washer

Lock Washer

Nut

Figure 8

Circuit

Protector

Chassis

Ground

Red

Black

Figure 9

Grommet

Tie Strap

Be Prepared