Installation instructions, Save these instructions – King Electric SCM User Manual

Page 9

9

SAVE THESE INSTRUCTIONS

INSTALLATION INSTRUCTIONS

KING ELECTRIC MFG CO · 9131 10TH AVENUE SOUTH · SEATTLE, WA 98108 · PH:206 762 0400 · FAX: 206 763 7738 · www.king-electric.com

Electrical Installation

Install junction boxes in the location (s) planned during the design process (Refer to page 6 under “Determine Junction Box(s) Location”).

Install conduit and branch circuit wiring from the circuit breaker panel to the control location, and from the control to the junction boxes.

Follow local code for wire size, conduit requirements, and proper installation procedure.

Install conduit from the junction box to the edge of the slab to be heated. Extend this conduit into the slab edge about 2”-6” and attach a

bushing to the end to prevent damaging the cable/mat power leads.

Plan carefully if you are installing edge pavers, edge drainage systems, landscaping, or other items that affect where the conduit comes in.

If a slab sensor is to be embedded in the heating area, install conduit from the control location to the desired slab location. Follow the sensor

instructions for proper placement and connections.

Install the circuit breaker size and type as determined earlier. DO NOT connect the branch wiring to the breaker yet.

Label the circuit breaker in the panel which feeds this Snow Melt system with “Snow Melt” or similar.

Sensor Installation

Installing a Feeder Cable

A feeder cable for a sensor may be needed. A 50’ (15m) cable is supplied with each sensor. Approx. 1.5’ (0.5m) of this cable should be coiled

inside the bottom of the sensor tube. The remaining cable may be lengthened. The feeder cable must be four wire cable.

Installing a Sensor and a Conduit

The sensor and the conduit may be installed in connection with the actual construction work and connected at a later date. The following applies

for all types of installations:

Ensure that the conduit is sealed when the concrete is poured.

The conduit must be positioned so that it is flush with the surrounding terrain. The sensor must be placed so that the upper brass sur-

face is horizontal.

The base below the tube must be hard, e.g. a concrete tile, in order to ensure that the sensor is not pushed into the ground if for exam-

ple a vehicle runs over it. The tube is designed to be mounted on a plate using the two screw holes inside the conduit.

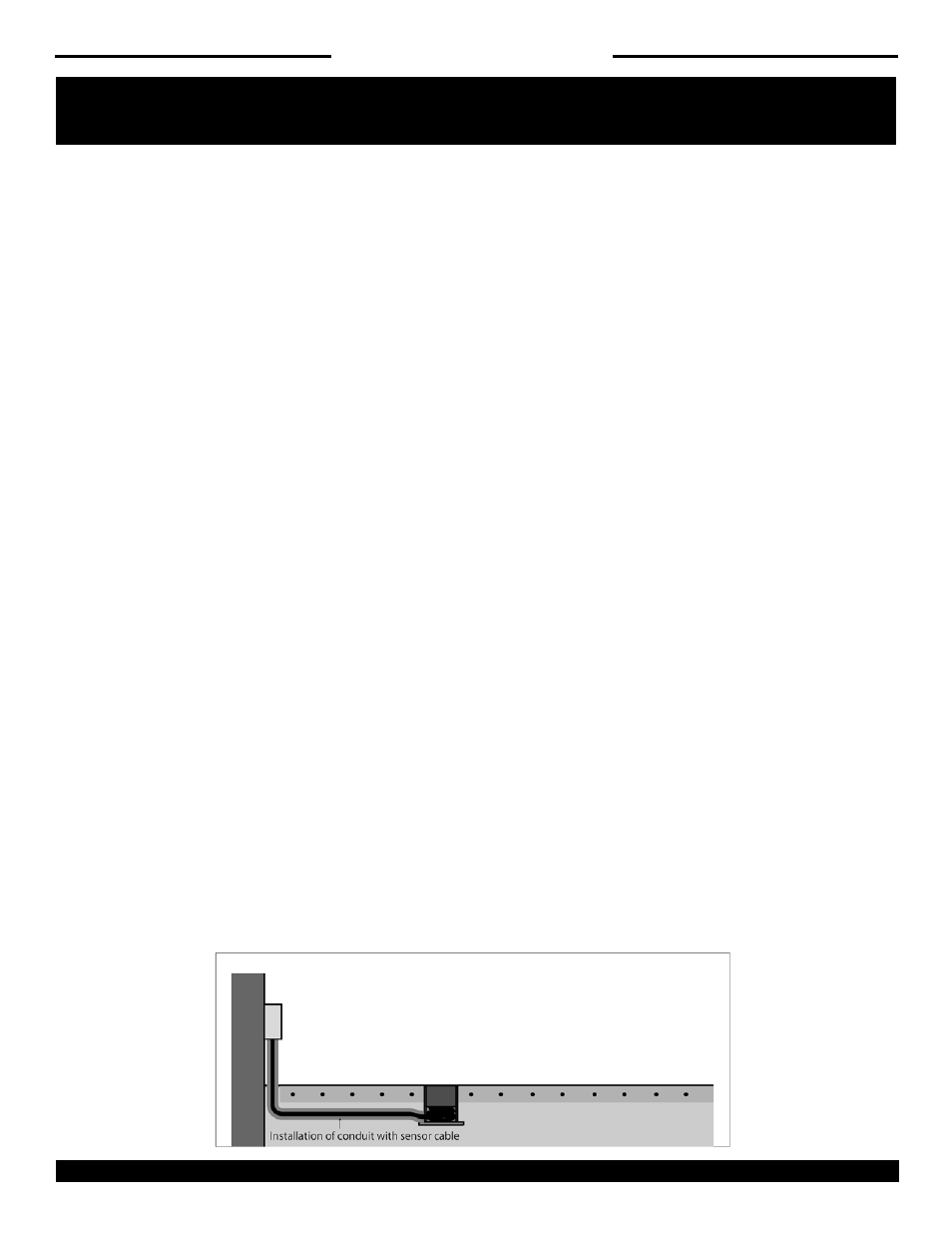

A metal/plastic pipe, through which the sensor cable may be passed, should be run as far as the sensor conduit.

Coil approx. 1.5’ (0.5m) of the sensor cable inside the conduit.

Place the sensor inside the tube until it is horizontally flush with the edge of the conduit and resting on the internal collar inside the con-

duit. The sensor may be extracted at a later date using the two holes found around the edge of the sensor conduit. The grooves on the

outside of the sensor should correspond with the holes in the conduit.