KB Electronics KBWM-240 User Manual

Page 8

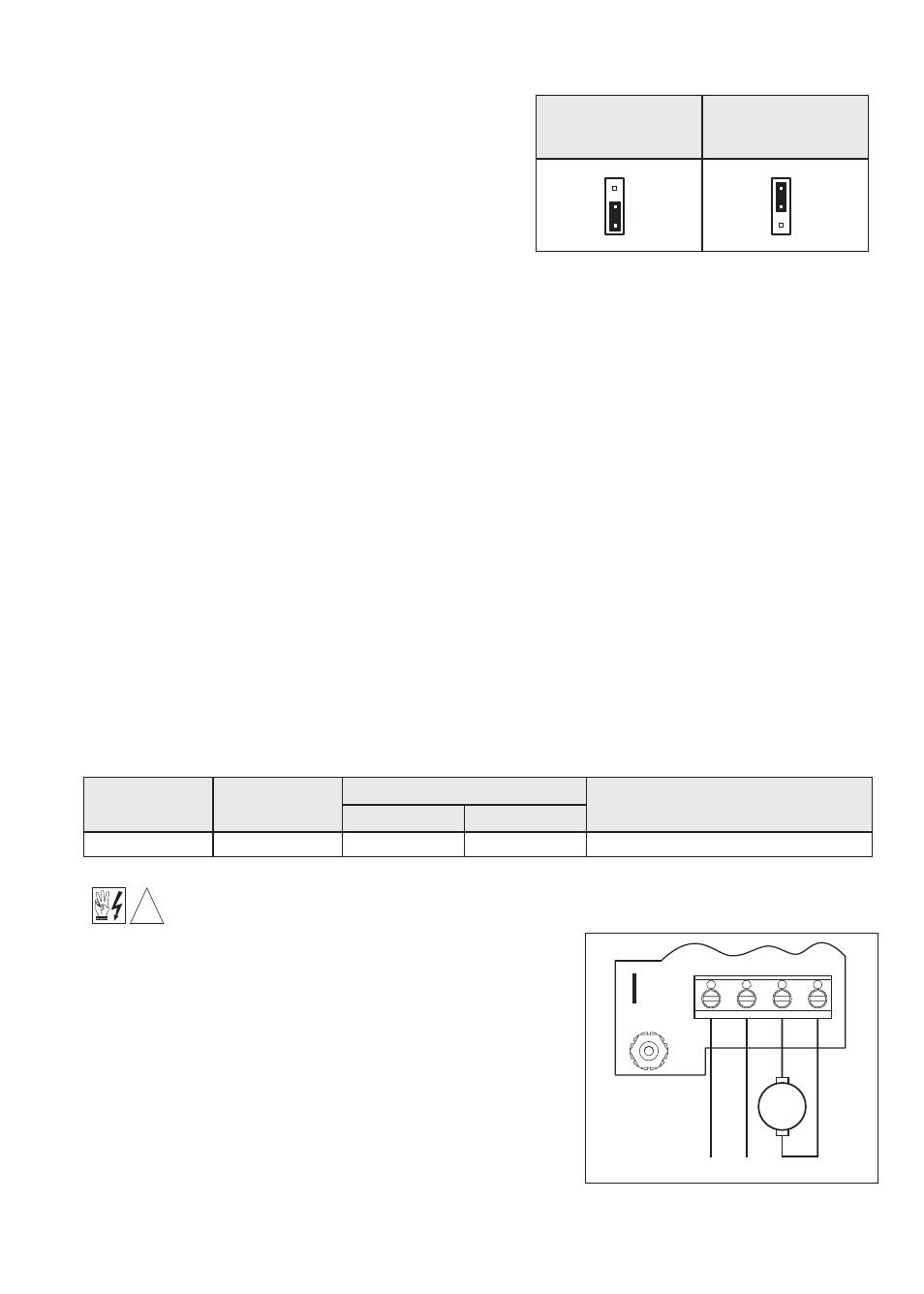

D. Jumper J2 is provided on Model KBWM-240 only

and is factory set to “180V” position. For step-

down operation (208/230 Volts AC line input and 0-

90 Volts DC output), set J2 to the “90V” position.

See Figure 3.

III.

MOUNTING

The KBWM™ is mounted via the rear cover

mounting strap. Before attempting to wire the

control, locate the mounting holes using the rear

cover as a template or use the dimensions as shown in the outline drawing. (See Figure 2,

page 4.) Be sure the control is mounted on a flat surface in a location where it will not be

exposed to contaminants such as water, metal chips, solvents or excessive vibration and/or

temperature extremes. Note: Allow adequate clearance around control to permit motor and

AC power cables to enter through the Bx knockouts on bottom of enclosure.

When mounting in an airtight enclosure, the air space should be large enough to provide ade-

quate heat dissipation. It is recommended that an enclosure with minimum dimensions of 12”H

x 12”W x 6”D (300mm x 300mm x 150mm) be used. The maximum allowable ambient temper-

ature at full rating is 50 ºC (122 ºF). Consult the Sales Department if more information is required.

Note: The KBWM™ can be oriented so that the AC power and motor wiring can be brought

in from the top of the control. Mount the rear cover so that the Bx knockouts are located on

the top by rotating the rear cover 180º. The front cover is then installed right side up using

the four (4) 6x32 screws previously removed from the top and bottom of the enclosure.

After wiring the front cover, install the mating rear cover with the four (4) 6x32 screws previ-

ously removed from the top and bottom of enclosures.

IV.

WIRING

Be sure the AC power is “off” before wiring control. Read Safety Warning on page 1 before

attempting to use this control.

WARNING!

To avoid erratic operation, do

not bundle AC line and motor wires with

potentiometer, voltage following, enable, inhibit or other

signal wiring. Use shielded cables on all signal wiring

over 12” (30 cm) – The shield should be earth ground-

ed on the control side only. Wire the control in accor-

dance with the National Electrical Code requirements

and other codes that may apply to your area.

A. AC Line – Wire the AC power to terminals L1 and

L2. Be sure that the control model corresponds to

the correct AC line input voltage. Model

KBWM–120 is for 115 VAC 50/60 Hz and model

KBWM–240 is for 208/230 VAC 50/60 Hz. See

Figure 4.

6

!

3.5

Maximum Tightening Torque

(in-lbs)

Supply Wire Gauge

Terminal Block

Designation

Connection

Designation

TB1

L1, L2, A+, A-

22

14

Minimum

Maximum

TABLE 5 – TERMINAL BLOCK WIRING INFORMATION

SW6

L2

L1

BLU

A+

A-

TB1

M

MOTOR

-

+

AC LINE

FIGURE 4 – AC LINE & ARMATURE

CONNECTION

180V

90V

180V

90V

J2 Set for

180 Volt DC Motors

(Factory Setting)

J2 Set for

90 Volt DC Motors

(Step-Down)

FIGURE 3 – MOTOR VOLTAGE SELECTION

(MODEL KBWM-240 ONLY)