KB Electronics KBMG-212D User Manual

Page 26

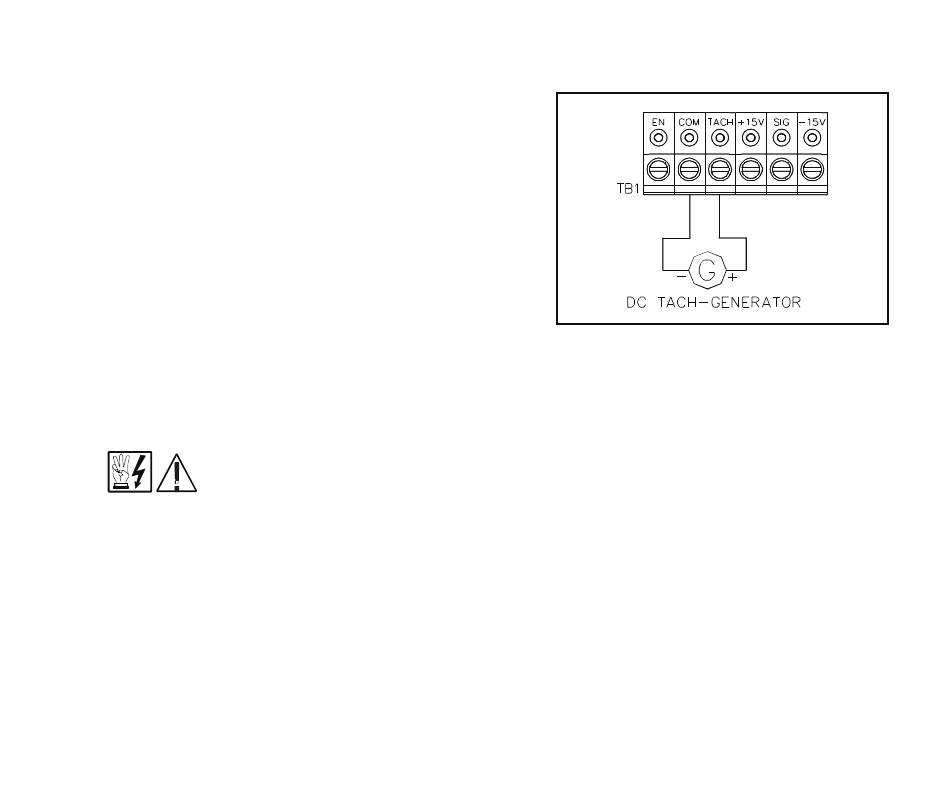

FIG. 17 – TACH-GENERATOR

FEEDBACK

i. Regen to a stop using terminals EN and COM on terminal block TB1 –

When a contact is opened between terminals “EN” and “COM,” with jumper J6

in the “RTS” position, the motor will regeneratively brake to a rapid stop.

Application note (See fig. 15): If controlled regen to stop is required, a contact

can be installed in series with the signal “SIG” connection. The braking time will

be equal to the REV ACCEL setting when the motor is in the forward direction,

and equal to the FWD ACCEL setting when the motor is in the reverse direction.

Note: J4 must be in the “15V” position. (See fig. 11D, p. 19.)

ii. Coast to a stop using terminals “EN” and “COM” on terminal block TB1 –

If coast to stop operation is required, move jumper J6 to the coast to stop (CTS)

position. When the contact is opened between “EN” and “COM,” the motor will

coast to a stop. See fig. 16.

ENABLE

OPEN TO REGENERATE TO STOP

FIG. 15 – REGENERATE TO STOP

ENABLE

OPEN TO COAST TO STOP

FIG. 16 – COAST TO STOP

*FWD Accel and REV Accel do not affect the stopping time when the enable circuit is opened.

23

H. Tach-generator Feedback – The KBMG-

212D is factory set for armature feedback,

which provides good load regulation for most

applications. For superior load regulation,

analog tach-generator feedback can be

used.

Wire the tach-generator so that the polarity of

the tach-generator is the same with respect

to the input signal polarity (see fig. 17).

Note: If tach-generator is wired with reverse

polarity, the motor will run at full speed.

Note: Jumper J3 must be set to the proper

position for tach feedback. See sec III, C, p. 9 and fig. 2 on page 10.

Note: Check

tach voltage polarity with respect to input signal if polarity does not match reverse

tach leads.

Be sure AC line is disconnected when rewiring tach-generator.

VI. FUSING.

Armature Fuse – It is recommended that the correct size armature fuse be installed,

depending on the rating of the motor and form factor (RMS/AVG current). Fuse type

should be Littelfuse 326 ceramic or Buss ABC, or equivalent. A fuse chart is presented

below which suggests appropriate armature fuse ratings. However, the specific

application may require larger fuse ratings based on ambient temperature, CL set point

and duty cycle of operation (see table 8, p. 25). Fuses may be purchased from your

distributor. Wire fuse in series with armature lead.

24

J6

CTS

RTS

J6

CTS

RTS