Harwin Z30-021 User Manual

Page 5

IS-36 Issue: 2 Date: 27.07.12 C/Note: 11786

Page 5 of 7

Correct crimp height, as per crimp height values given on front page.

A destructive pull-off force test should also be performed occasionally, to confirm the hand crimp

tool is still operating correctly. The correct values for this test are given on the front page of this

instruction sheet. Insulation should be stripped back beyond insulation crimp area before

preparing samples for pull-off force test.

ASSEMBLY – CRIMP INTO HOUSING

The completed crimp can now be inserted into the appropriate Trio-Tek crimp housing. For larger

wire sizes, no other tooling should be required for this operation; the crimps can be pushed in by

hand. Crimps are assembled into the mould with the retaining tang towards the outer edge of

the housing. With thinner wires, it may be helpful to push onto the back of the crimp.

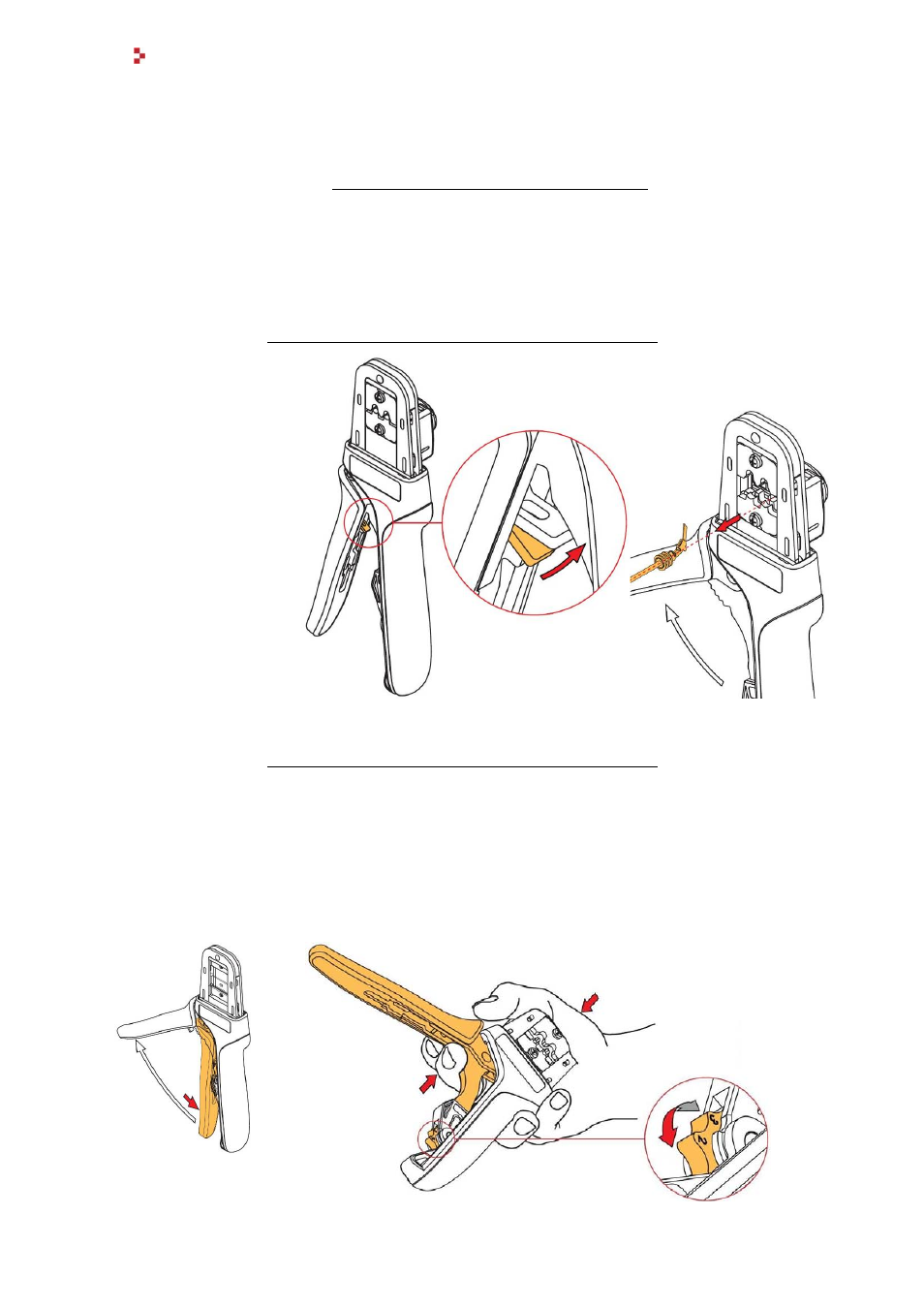

TROUBLESHOOTING – MISCRIMPS OR JAMS

Should the tool become

stuck or jammed in a

partially closed position,

Do Not

force the handles

open or closed

. There is

a ratchet release lever

located inside the

movable handle.

Pressing up on this lever

will release the ratchet,

and the handles should

then easily open. The

jam or miscrimp can then

be removed.

TROUBLESHOOTING – LOW PULL-OFF FORCE

This tool is supplied as new, set to the right preload force necessary to crimp the contacts.

However, over time, this force may fall off slightly. The tool can be adjusted to cater for this

wear, and raise the preload force to give correct crimps.

If you need to carry out this procedure, Harwin recommend that you crimp a number of samples

before and during adjustment, until the pull-off force achieved is up to your standards.

.

Ensure that the crimp tool

is at the fully open

position

Hold the hand tool as shown in the above figure, and

squeeze the link bar in towards the top of the tool. This

releases the preload adjustment wheel.