Harwin Gecko User Manual

Page 2

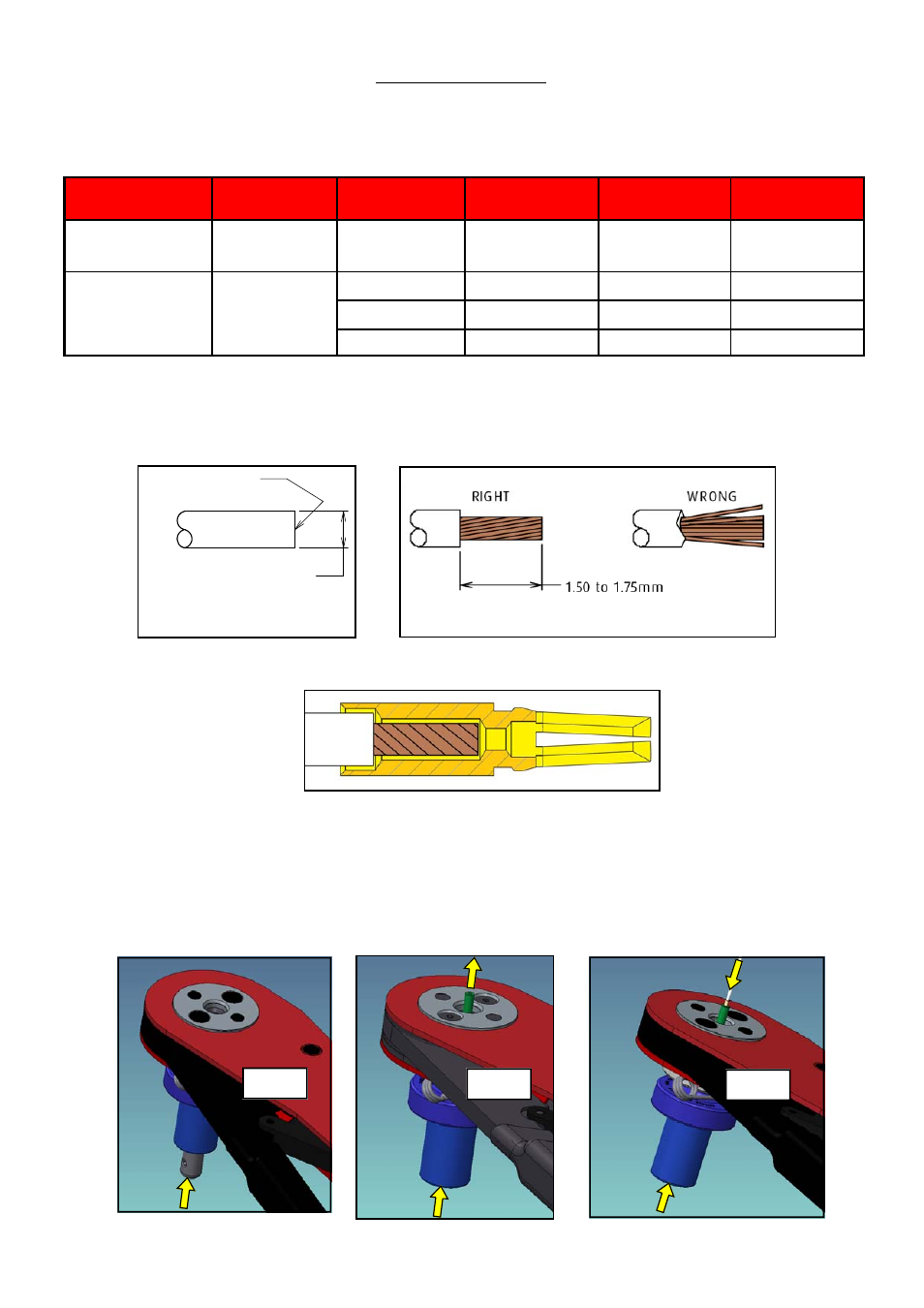

Crimping Procedure

1.

Ensure that the wire to be crimped is within the specified range of sizes for the contact and the crimp tool. Failure

to use the specified wire size will result in poor quality crimps and possible tool damage.

Table 1

2.

Cut the end of the cable to be terminated so that there is a clean cut end (Figure A). Strip the cable to the correct

length (Figure B) using a PTFE Wire stripper, preferably with adjustable rotating cutter. This should result in all the

strands lying together neatly. If the lay of the strands is disturbed, it may be re-imposed with a slight twist.

3.

Load the terminated end of the cable into the crimp barrel of the socket. Ensure the wire is fully inserted, with all

strands in place (see Figure C, contact may not be as shown).

4.

Apply pressure to contact positioner plunger in direction shown by the arrow (See Figure D). Release pressure to

ensure plunger is free moving and returned to default position without jamming. Once you are satisfied with

plungers operation (See Figure D), re-apply pressure in direction shown by the arrow.

5.

Hold positioner in the load position (See Figure E).

6.

Continue holding positioner in the load position and locate the crimp contact with cable, fully into the positioner

(see Figure F).

Contact

Crimp Type

Wire Gauge

(AWG)

Stranding (mm)

Crimp Tool

Setting

Minimum pull-

off force

G125-00100XX

G125-10100XX

Large Bore

26

7/0.15

6

18N

G125-00200XX

G125-10200XX

Small Bore

28

7/0.12

5

12.5N

30

1/0.25

5

7N

32

7/0.08

5

4N

Clean cut

Ø0.72mm max 28-32 AWG

Ø0.80mm max 26 AWG

Figure C

Figure A

Figure B

Figure D

Figure E

Figure F

IS‐37 Issue: 2 Date: 11.03.14 C/Note: 12412

Page 2 of 3