General information, Tool preparation, Crimping procedure – Harwin M22520/2-01 User Manual

Page 2

IS-01 Issue: 5 Date: 19.07.12 C/Note: 11782

Page 2 of 3

GENERAL INFORMATION

The Hand crimp tool M22520/2-01 consists of a basic hand tool, which should be used with a

positioner.

The contact is correctly crimped when the tool is free to open at the fully closed position, i.e.,

when the ratchet releases. The tool cannot be opened without completing the cycle.

TOOL PREPARATION

1.

Check that the tool is in the open position. Remove the safety clip from the positioner

guide (do not discard).

2.

Insert the Positioner into the positioner guide and turn it 90° in the direction shown on the

tool, until the bayonet pins lock.

3.

Install the safety clip back into the positioner guide (optional).

4.

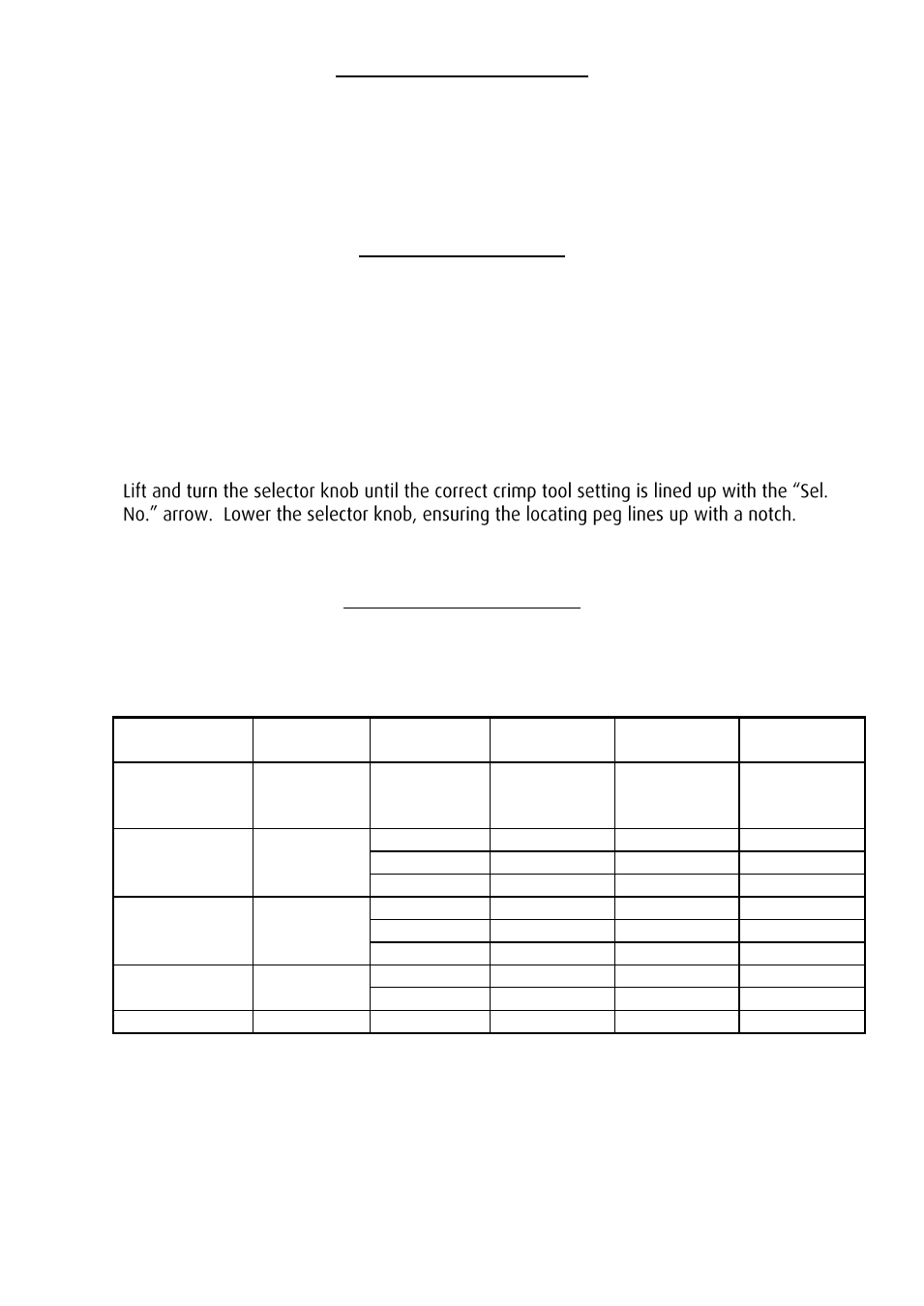

Check Table 1 for the correct crimp tool setting of the wire size you wish to crimp.

5.

Remove the safety clip from the selector knob (do not discard).

6.

7.

Install the safety clip back into the selector knob.

CRIMPING PROCEDURE

1.

Ensure that the wire to be crimped is within the specified range of sizes for the contact and the

crimp tool. Failure to use the specified wire size will result in poor quality crimps and possible tool

damage.

Table 1

Contact

Crimp Type

Wire Gauge

(AWG)

Stranding

(mm)

Crimp Tool

Setting

Minimum

pull-off force

M80-01100XX

M80-04000XX

M80-19400XX

Large Bore

22

19/0.15

6

50N

M80-01300XX

M80-04100XX

M80-19500XX

Small Bore

24

7/0.2

6

44N

26

7/0.15

6

25N

28

7/0.12

6

12.5N

M80-01900XX

Extra small

bore

28

7/0.12

5

12.5N

30

1/0.25

4

7N

32

7/0.08

4

4N

M80-05500XX

Power Crimp

20

19/0.2

8

85N

18

19/0.26

8

140N

K36XX-46

Power Crimp

18

Variable

8

142N

2.

Cut the end of the cable to be terminated so that there is a clean cut end (Figure A). Strip the cable

to the correct length (Figure B) using a PTFE Wire stripper, preferably with adjustable rotating cutter.

This should result in all the strands lying together neatly. If the lay of the strands is disturbed, it

may be re-imposed with a slight twist.