Calibration, Sampling, Calibration adapter setup (figure 10) – SKC 225-70A IOM Inhalable Dust Sampler with MultiDust Foam Discs User Manual

Page 7: Calibrating pump flow rate

7

Calibration

Calibrate pump fl ow rate using a primary standard calibrator, IOM Calibration

Adapter accessory, and a representative loaded IOM Sampler in line.

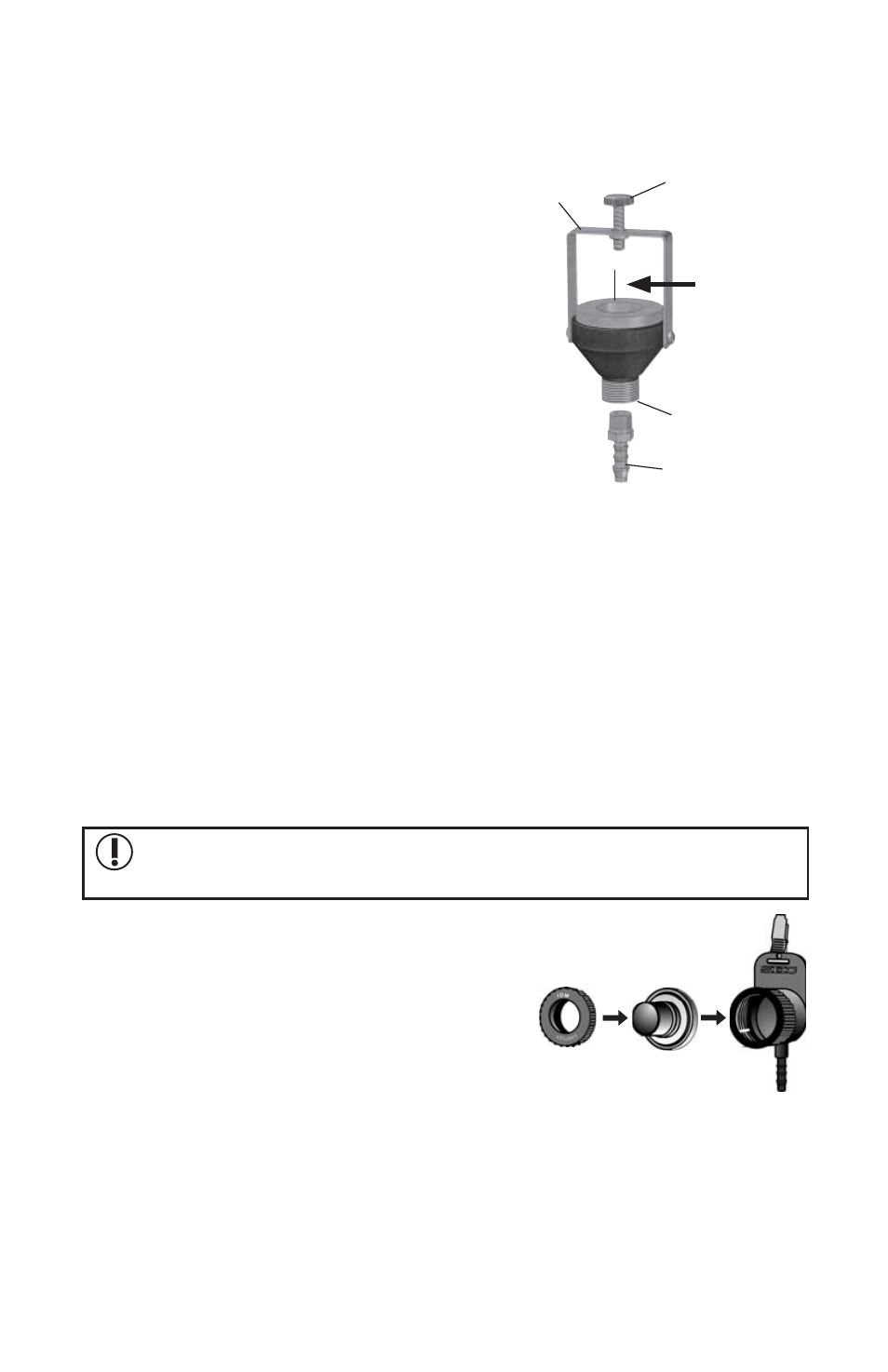

Calibration Adapter Setup (Figure 10)

1. Push an IOM Sampler loaded with a

representative fi lter and cassett e through

the hinged bracket and place inlet against

the adapter’s foam ring.

2. Clamp IOM in place with plastic clamping

screw until foam ring compresses by 1 mm.

Ensure IOM inlet is centered.

3. Screw supplied hose barb into threaded hole

in calibration adapter inlet.

4. Use a length of fl exible tubing to connect

hose barb to calibrator outlet.

5. Remove sampler dust cap from outlet.

6. Connect IOM outlet to the inlet of a sample

pump.

Calibrating Pump Flow Rate

Calibrate pump fl ow rate using the IOM Calibration Adapter accessory and an IOM

sampler loaded with a representative fi lter and cassett e in line.

1. Insert IOM with loaded fi lter cassett e into the calibration adapter (see Calibration

Adapter Setup and Figure 10).

2. Calibrate pump fl ow rate to 2 L/min. See calibrator and sample pump operating

instructions for additional information.

3. Disconnect IOM from pump and calibrator and remove representative cassett e.

Set aside for fl ow rate verifi cation aft er sampling.

Sampling

Wear powder-free gloves when handling cassett es. Users may wish to

use sterile gloves depending on the contaminant of interest.

1. Remove a newly loaded cassett e from its

transport clip and remove the cassett e cover.

Ensure the O-rings are fi tt ed correctly inside

the sampler housing body. Insert the cassett e

into a clean IOM housing body. Screw the

front plate into the housing body. Tighten

to achieve a good seal (Figure 11).

2. Clip onto a worker’s clothing in the breathing

zone (Figure 12).

3. Ensure sampler dust cap is removed from the

outlet. Using fl exible tubing, connect outlet of

the IOM Sampler with the inlet of a sample

pump calibrated to 2 L/min (Figure 12).

4. Remove cover, start pump, and sample for

the time specifi ed in the method used.

Figure 11. Insert loaded cassette

in sampler body and screw on

front plate.

Figure 10. IOM Calibration

Adapter

Foam ring

Plastic

clamping

screw

Hinged

bracket

Adapter

inlet

Hose barb

Insert IOM here,

inlet side down