0 installation – Ronan X55-600 Series User Manual

Page 4

Temperature Drift: 0.01% of span per °F

from 30 to 150°F (.025% below 30°F).

Feed Flow (Output) Capacity: 3.0 SCFM at

20 psi supply, 10.5 SCFM at 100 psi supply.

Bleed Flow (Exhaust) Capacity: 3 SCFM

(20 SCFM optional).

Pneumatic Connections: 1/4" MPT

Electrical Connection: Screw compression

(#30 to #16 awg. wire).

Weight, Sizes & Ratings:

Model X55-600-GP

X55-600-N4 X55-600-Ex

Rating General Purpose NEMA4

Exp. Proof

Weight 1.5 lbs.

1.75 lbs.

3.0 lbs.

Size(in.) 3x2x5.2"

3.8x2.3x6.8" 4x4x5.4"

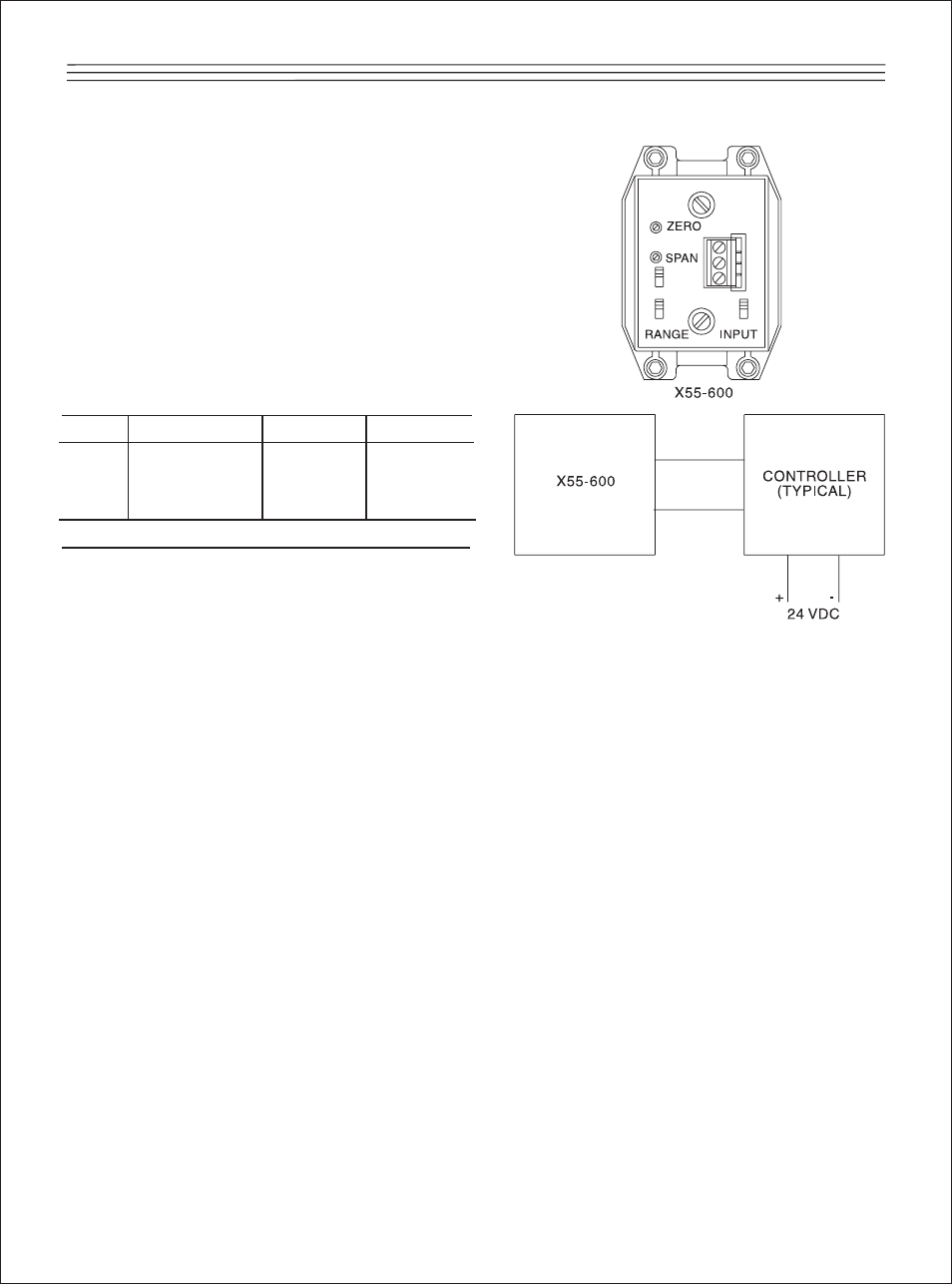

3.0 INSTALLATION

3.1 Electrical Connections

The Electrical connections are made to

screw terminals located at the top of

the module (See Figure 1). The “+” and

“-” terminals are identified on the top

cover. If the NEMA 4 watertight cover is

used, the wire entry is through a 1/2-14

NPT female conduit opening.

Remove the top cover of the watertight

enclosure for access to the screw termi-

nals. The explosion-proof enclosure also

utilizes a 1/2-14 female conduit opening

for wire entry. The wires are then routed

internally to the “+” and “-” terminals

(See Figure 1).

3.2 Pneumatic Connections;

General Purpose, NEMA 4 and

Explosion-Proof Models

Connect the supply pressure tubing to

the 1/4-18 NPT female inlet labeled

“IN”. A dry, clean and filtered air supply

in the range of 20 to 120 psig is

required (at least 5 psig over the maxi-

mum output). The regulated pressure

output is via the 1/4-18 NPT female out-

let labeled OUT. The output piping

should be 1/4" pipe or 3/8" tubing. On

NEMA 4 and explosion-proof models,

position air vent covers to prevent water

from entering the unit.

It is extremely important that the X55-

600 air supply is clean (oil and dirt free)

and dry (moisture free). It is recom-

mended that Ronan's X55-77-4, or a

similar quality filter/preregulator, be

installed with every I to P. Unit malfunc-

tions due to dirt or moisture damage

are not covered under warranty.

Figure 1: Typical Wiring.

+ +

- -

2