Fluid & air pressure requirements, Fluid valve control – Ransburg Turbodisk 2 Assembly 78715 User Manual

Page 21

Turbodisk 2 - Operation

17

FLUID & AIR PRESSURE

REQUIREMENTS

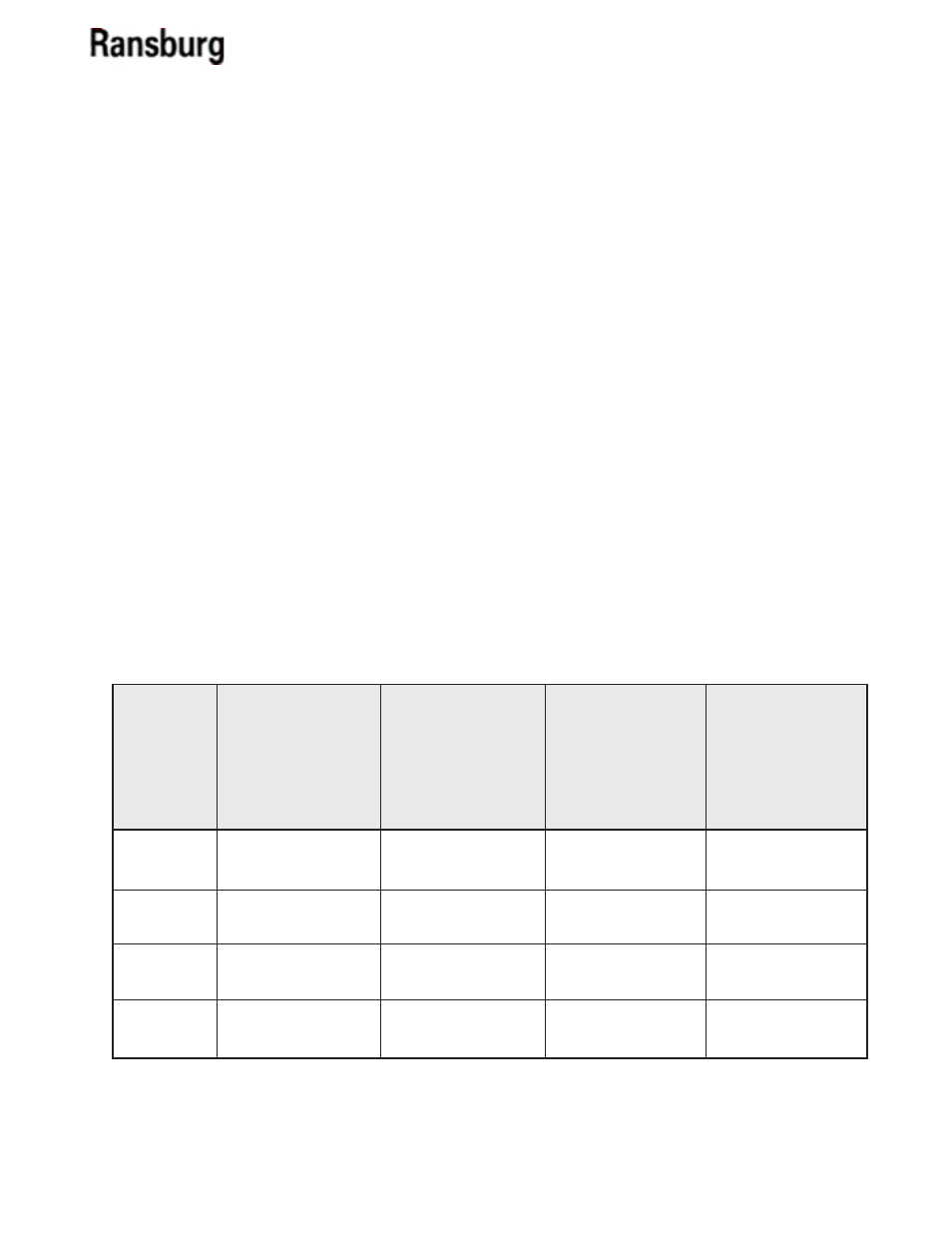

-REFER TO FIGURE 4

Fluid and air pressure requirements are dependent

on the fluid trigger valve configuration.

Figure 4: Turbodisk 2 Fluid & Air Pressure Requirements

Note: Trigger/dump valves (CCV-403-SS) are rated to 300 psi maximum inlet fluid pressure but are

limited to the lower pressure limit of the fluid regulators.

3-Way ON/OFF

(18283)

78718-11 thru -20

Air Pilot Fluid

Regulator

Air Inlet Trig/

Dump Valve

Fluid Inlet

Pressure

Solvent Inlet

------------------

120 psi max.

300 psi max.

30-60 psi max.

No Valves

78718-01 thru -10

------------------

------------------

------------------

------------------

Trigger/Dump

w/High Flow

(70171-04)

Regulator

78718-21 thru -30

100 psi max.

70-100 psi

80-100 psi max.

30-60 psi max.

Trigger/Dump

w/Low Flow

DR-1 (74151)

Regulator

78718-31 thru -xx

100 psi

70-100 psi

80-100 psi max.

30-60 psi max.

FLUID VALVE CONTROL

Trigger and Dump

-REFER TO FIGURES 4 & 25

The fluid valves in the Turbodisk 2 are actuated by an

air signal. The air pressure must exceed 70 psi to assure

proper actuation of the valve. Applying air to the valve

actuator turns on the fluid flow for that valve.

The trigger valve controls the paint flow to the disk.

When actuated, paint flows through the valve to

the fluid tube. The disk should be spinning at a RPM

speed that is fast enough, (that when fluid is turned

on) to enable the fluid to flow through the disk paint

passage holes and be atomized.

The dump valve controls the paint flow through the

dump line. When actuated, paint flow is directed to the

dump return line. This provides a method of rapidly

removing paint from the incoming line for cleaning

and/or color change. Normally, the dump valve is not

actuated at the same time as the paint trigger valve

since the trigger valve is intended to cause the fluid

flow to the disk at the prescribed input pressure.

LN-9240-02.1