Ransburg, Turbine tests, N o t e – Ransburg RMA202 Test Stand 77918-08 User Manual

Page 16: Rma-202 test stand - installation

7. Manually turn up the water pressure to 70 psig

(read on the front panel) by adjusting the pres-

sure regulator on the pressure pot. Verify by

looking at the pressure gage for fluid pressure.

8. Verify the test station test bell cup is still on the

applicator.

9. Turn “Fluid Enable” Paint #1, Paint #2, and sol-

vent In to the “On” position.

10. Turn “Applicator Enable” switches Bell Sol-

vent, Paint #1, and Paint #2 Trigger (if equipped)

to the “On” position.

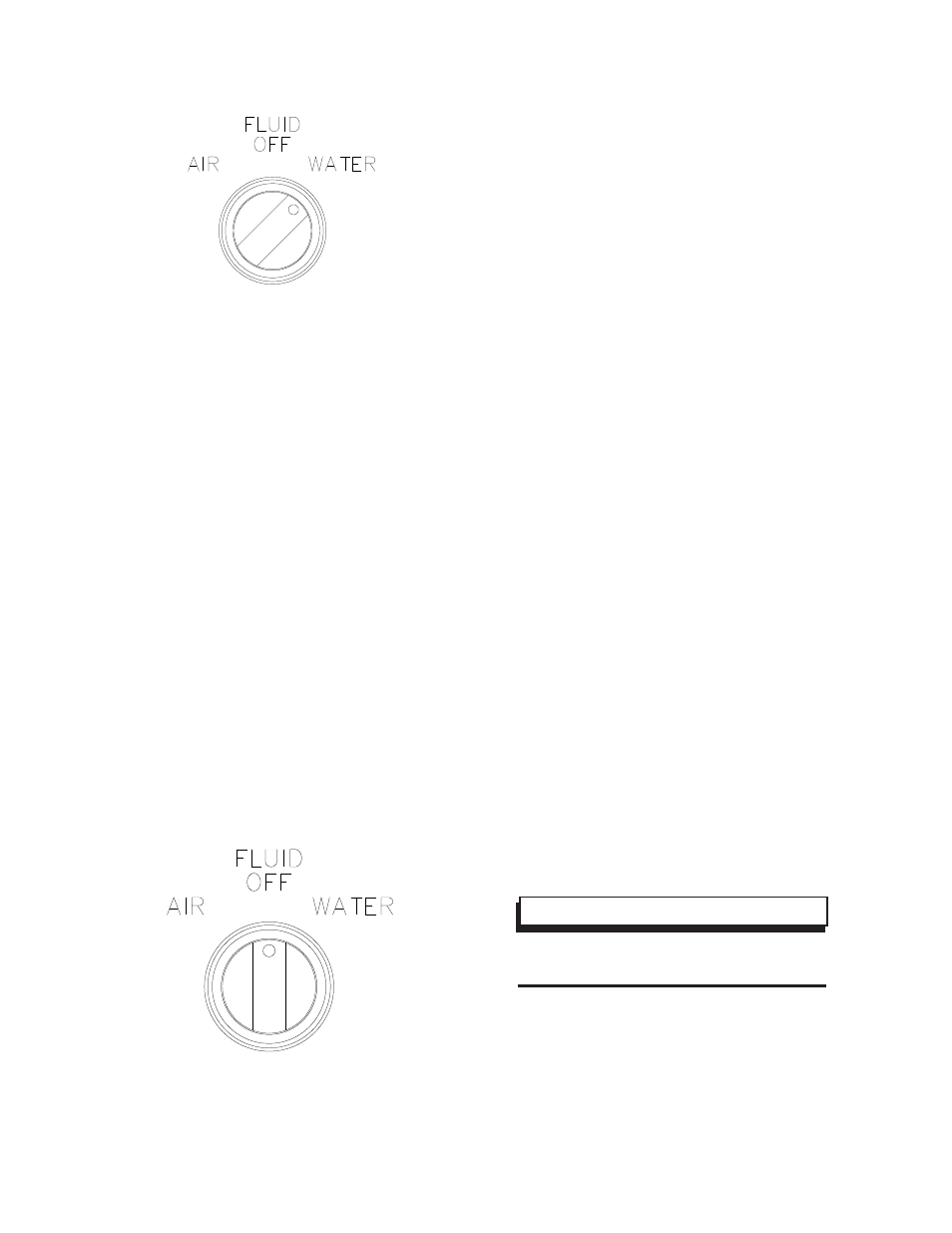

11. Visually inspect each of the coiled fluid tubes

to verify there is fluid in them.

12. Visually inspect around the applicator to in-

sure there are no visible water leakage.

13. Turn the fluid selector switch to the “Off” posi-

tion.

Figure 14: Fluid Selector Switch Position

for Water Tests

Figure 15: Fluid Selector Switch “OFF” Position

N O T E

> Bell cup and shroud must be attached to

end of turbine.

14. Observe the test pressure gauge for 2 to 3

minutes. The leak pressure should stay con-

stant over this period. If it does not, locate the

source of the leak, repair it and retest the ap-

plicator.

15. If the system does not hold pressure, visually

inspect for leaks. Potential areas are paint and

dump valves and their seats.

16. Turn the fluid selector switch back to air. De-

pressurize the pressure pot.

17. Actuate the dump triggers and blow out the

lines per the procedure outlined in the “HV

Troubleshooting” in this section.

18. Remove the test bell from the end of the appli-

cator. Adequately blow out all fluid in the coil

and upper section of the applicator. Install the

production bell cup and shroud per the instruc-

tions in the most current RMA-202 applicator

service manual.

19. Dump contents of “dump bucket.”

TURBINE TESTS

The purpose of this test is to verify the applicator

rotates properly and sprays reasonable well. With

de-ionized or distilled water as the test fluid, it is

difficult to accurately access the spray performance

characteristics. However, it can give a relative

indication of how the bell will spray in production.

RMA-202 Test Stand - Installation

14

Ransburg

LN-9527-00.1