Ransburg, Test triggers, N o t e – Ransburg RMA202 Test Stand 77918-08 User Manual

Page 14: Hv troubleshooting, Checking plumbing in the bell), Verify trigger functions with air, Rma-202 test stand - installation

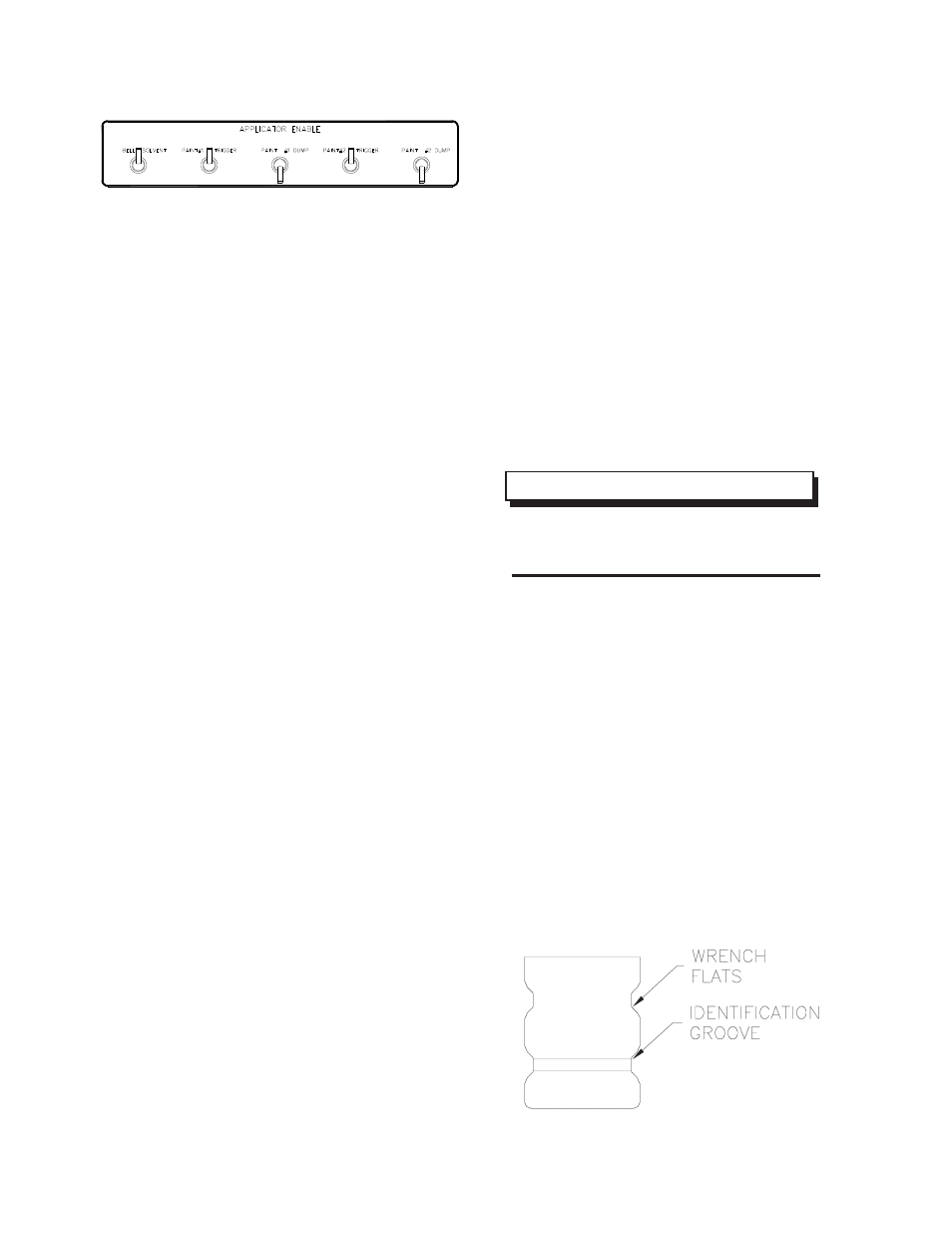

Figure 11: P#1 & P#2 Trigger Switches

Figure 12: Pressure Test Bell

N O T E

> For this part of the test, the spin

guard should be in the down position.

10. Turn off all triggers.

11. Reinstall the front shroud, bell, and voltage

containment bag.

12. Restart voltage test, sections 4 through 6. All

current and voltage readings should meet the

listed specifications for the applicator to deliver

the performance that is expected from it.

Hv Troubleshooting

If there is zero kV reading at the MicroPak display

with the voltage adjust potentiometer turned fully

clockwise, there could be several different causes.

Some of the most likely to cause the problem are:

1. The cascade connector is loose, was not prop-

erly connected at the wiring harness, or prop-

erly aligned. Remove applicator from mount-

ing plate and verify alignment marks.

2. The connection spring (78997-00) inside the

manifold may be missing. This small spring

may have been forgotten during the rebuild of

the applicator. For information on placement

and location of this spring, consult the most

current RMA-202 service manual for the appli-

cator (turbine motor must be removed to in-

spect spring placement).

3. The cascade assembly (79010-00) may be

bad. Install a known good cascade in the ap-

plicator and check for improved results. When

reinstalling the cascade, use LSCH0009, di-

electric lubricant around the circle labyrinth at

the spring connection end of the cascade as-

sembly (79010-00).

TEST TRIGGERS

(Checking Plumbing In The Bell)

The purpose of the trigger test section is to guar-

antee all the triggers on the applicator have been

properly hooked up and when they receive an air

signal, they properly cycle.

Verify Trigger Functions With Air

Air is used in the initial test to reduce the mess

associated with water if the trigger valves or dump

valves have not been properly plumbed or rebuilt.

The following procedure describes the test of each

of the following valves in the applicator:

1. Insure that the MicroPak main power control is

in the “Off” position and High Voltage switch is

in the “Off” position.

2. Remove the shaping air shroud from the end

of the applicator using RPM-419 wrench.

3. Using (2) RPM-419 wrenches, remove the

bell from the turbine shaft.

4. Install the test bell (77981-00) and seal (77982-

00) using the RPM-419 wrench. Insure the test

bell is installed on the turbine shaft properly,

hand tighten only.

5. Turn the Fluid selector switch to the “Air” posi-

RMA-202 Test Stand - Installation

12

Ransburg

LN-9527-00.1