Ransburg, Pressurized water tests – Ransburg RMA202 Test Stand 77918-08 User Manual

Page 15

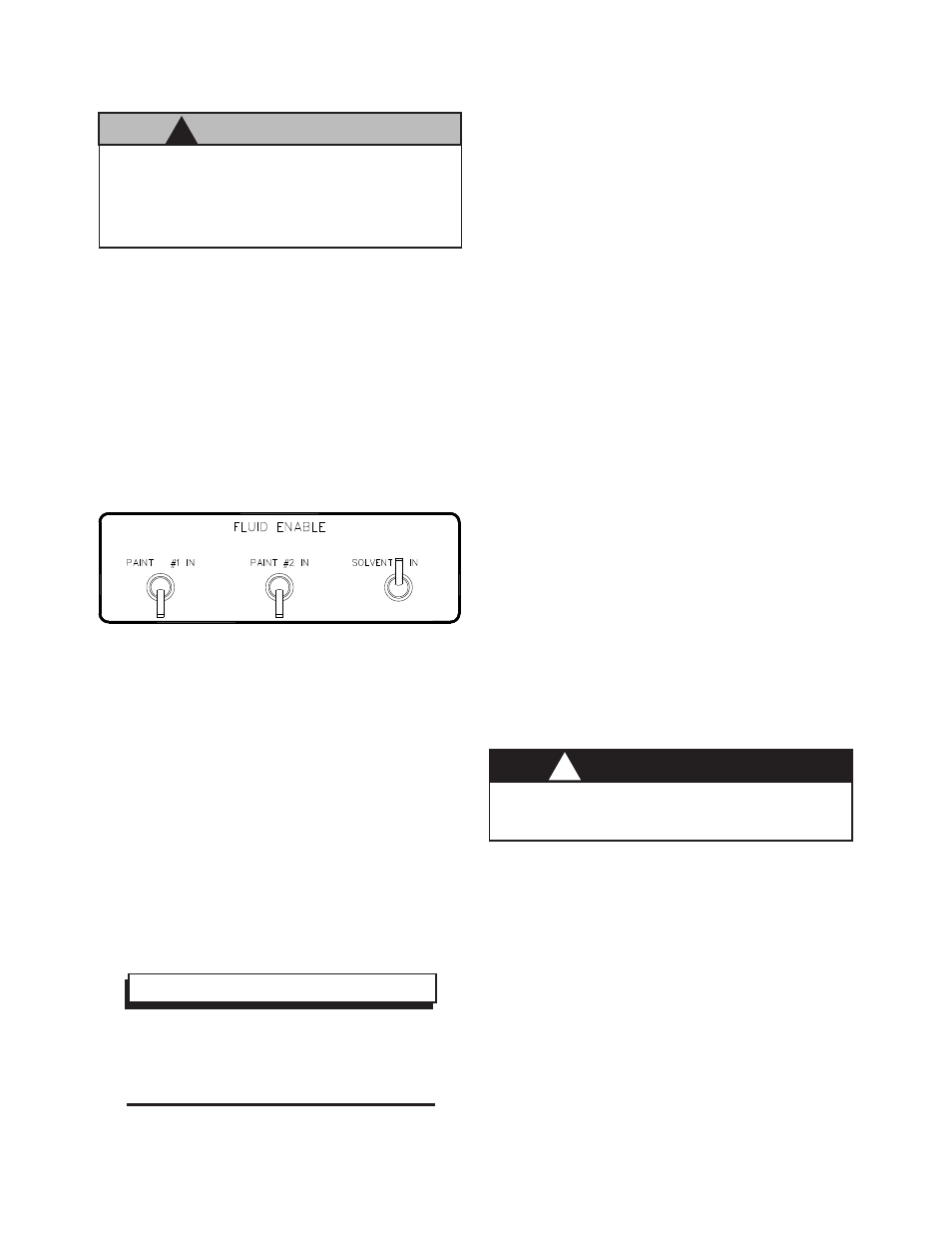

Figure 13: Bell Solvent Switch

N O T E

> For signal line verification consult the

most current RMA-202 applicator service

manual. Pull valves out of manifold.

tion (See Figure 7).

6. Trigger the bell solvent switch (See figure 13).

When this is triggered, you see the valve actu-

ate via a flag through the opening in the valve

cover. Each of the valve positions is engraved

on the fluid manifold. Once actuation function

is verified, turn switches to off position.

7. Each of the valve positions is engraved on the

C A U T I O N

!

> With the test bell and seal installed, DO

NOT attempt to rotate the turbine shaft.

Any attempt to rotate the turbine shaft WILL

CAUSE DAMAGE to the fluid feed tube.

W A R N I N G

!

> Never use solvent as a test fluid for this

device.

fluid manifold such as solvent, Paint #1, Paint

#2, etc. By triggering each of these functions,

verify visually each respective valve triggers

when its toggle switch is turned on. The trig-

ger functions that require verification are:

• Paint #1 Trigger

• Paint #1 Dump

• Paint #2 Trigger

• Paint #2 Dump

• Solvent

8. If the valves do not function as expected, re-

check to insure micro valves or micro valve

seats are properly installed and seated in “Fluid

Enable” and “Applicator Enable”.

PRESSURIZED WATER

TESTS

(Static)

The purpose of this section of the test is to verify

that each of the valves in the applicator will pass

fluid. Also, this test verifies all seals along the fluid

passages have been properly located to prevent

any fluid leakage.

To complete the pressurized water tests, complete

the following:

1. Insure all toggle switches are set to the “Off”

or “Down” position.

2. Position the applicator where any water

sprayed out of the bell may be collected and

properly disposed of.

3. Verify there is no residual pressure in the pres-

sure pot included with the test stand. Turn the

regulator adjustor on the pressure pot counter-

clockwise until all pressure is released. Pull

the bleed-off valve to release the pressure if

any.

4. Loosen the pressure pot clamps till the lid may

be removed from the pot itself. Fill the pres-

sure pot with de-ionized or distilled water.

5. Close the lid, tighten the lid clamps so that the

lid is secure and no air pressure may escape.

6. Turn the fluid actuation switch to water (See

Figure 14).

RMA-202 Test Stand - Installation

13

Ransburg

LN-9527-00.1