Gun and manifold assembly, See figures 4 and 5), Robot spacer plate – Ransburg Evolver Solvent Applicator 79190-XXXXXXXX User Manual

Page 22

17

Evolver Solventborne Robotic Atomizers - Installation

GUN AND MANIFOLD

ASSEMBLY

(See Figures 4 and 5)

The tubing, hose, and low voltage cable come bundled

from the factory. Pull the bundle through the robot

spacer plate and robot wrist carefully to prevent any

cuts on the cable or hoses. Use the six (6) socket head

cap screws (7959-32C) included with the rear manifold

tubing assembly to attach the rear manifold assembly

( 79156) to the robot spacer plate (see Table 1).

Connect each signal line as required per signal legend

for both English and Metric tubing bundles, table

following.

Robot Spacer Plate

The robot spacer plate is included with the robot

manifold assembly to increase life of the tubing

bundle. The extra spacing it provides, increases the

bend radius of the tubes and decreases the hose or

cable stress at the connector.

There is only one way the spacer plate may be as-

sembled to the mounting plate. The spacer plate has

an alignment pin that may only engage in one hole

position in the robot mount plate. This provides the

final position to top dead center of the robot.

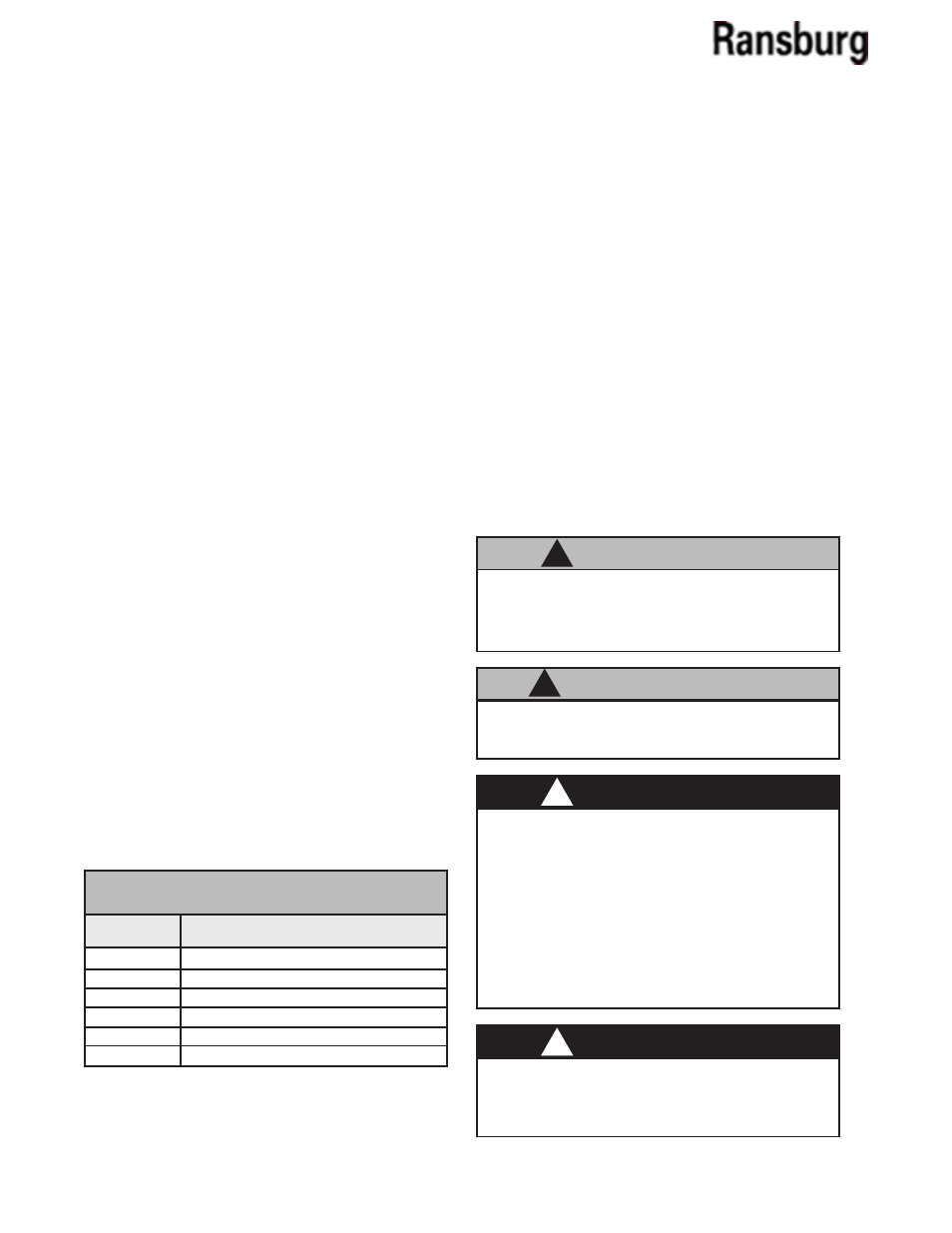

The six (6) robot spacer plates, Table 1, are available

for this product.

>

Do not exceed 100' combined length of the

low voltage cables.

C A U T I O N

!

79107-00

ABB Robots

78983-00

Fanuc P155, 145 Robots

79131-00

Fanuc P200 Robot

A10847-00

Adapter (Kawasaki-KE610L)

A10848-00

Adapter (Motoman-PX2850)

A10849-00

Adapter (Motoman-PX2900)

Part #

Description

TABLE 1 - SPACER PLATES

>

Leave 12-24 inches of extra length on all lines

to prevent extreme tension being applied to these

lines during robot movement.

C A U T I O N

!

>

Install and route the hoses and cable so that

they are NOT exposed to temperatures in excess

of 120

°

F. Ensure that all hose and cable bends

are NOT LESS THAN a 6 inch (15cm) radius and

are not subjected to more than 360

°

of torsional

twist. Failure to comply with these parameters

could cause equipment malfunctions that might

create HAZARDOUS CONDITIONS!

W A R N I N G

!

>

If a non-explosion proof junction box/termi-

nal strip is used, it must be located outside the

hazardous area.

W A R N I N G

!

For installations utilizing the LECU5004-XX Mi-

croPak Power Supply, connect the low voltage cable

(79008-XX) from the robot manifold assembly to the

LECU5004-XX MicroPak Controller or junction box.

If connecting to a junction box, use a junction cable

(77062-XX) to make the connection from the junction

box to the LECU5004-XX MicroPak. Make connections

as shown in Figure 4.

For installations utilizing the A10406-XX Evolver Mi-

croPak Power Supply, connect the low voltage cable

(A11353-XX or A11356-XX) from the robot manifold

assembly or junction box to the receptacle on the

rear of the A10406-XX power supply. To maintain

FM Approval, this cable must be secured to the

stress relief bar on the rear of the power supply. (See

"A10406-XX Evolver

MicroPak Power Supply" manual for further informa-

tion on connecting the low voltage cable.)

AA-03-02.11